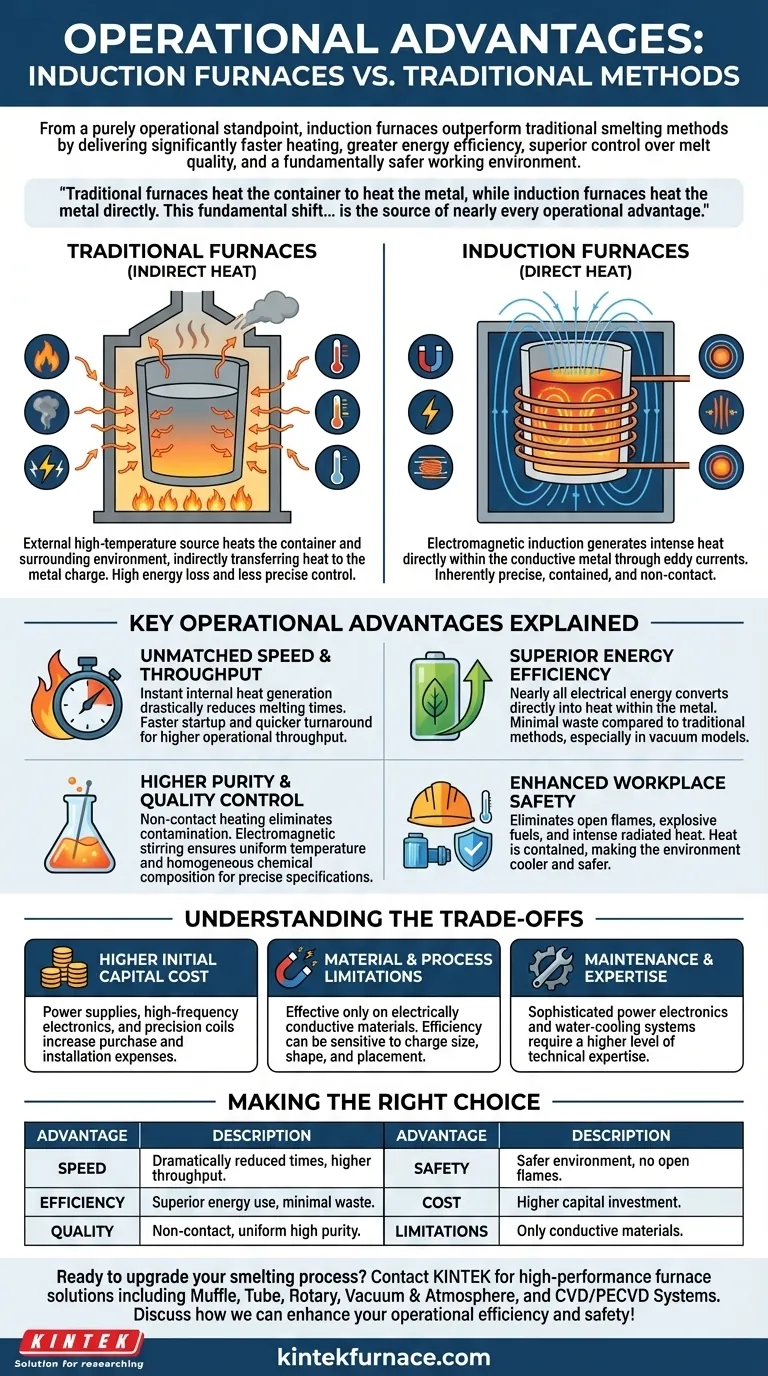

From a purely operational standpoint, induction furnaces outperform traditional smelting methods by delivering significantly faster heating, greater energy efficiency, superior control over melt quality, and a fundamentally safer working environment. This is achieved by using electromagnetic induction to generate heat directly within the metal itself, a process that is inherently more precise and contained than external combustion or electric arcs.

The core difference is simple: traditional furnaces heat the container to heat the metal, while induction furnaces heat the metal directly. This fundamental shift from indirect to direct heating is the source of nearly every operational advantage, eliminating the immense waste, imprecision, and safety hazards of older methods.

The Core Principle: Direct vs. Indirect Heating

To understand the advantages of induction, we must first compare the fundamental heating mechanisms. The difference is the key to appreciating the gains in efficiency, speed, and quality.

How Traditional Furnaces Work (Indirect Heat)

Traditional smelting, whether in a cupola, reverberatory, or electric arc furnace, relies on indirect heating. An external, high-temperature source is created—such as burning coke, gas, or creating an electric arc—and that heat is then transferred to the metal charge.

This process is inherently inefficient. A significant amount of energy is lost heating the furnace walls, the surrounding atmosphere, and the exhaust gases. Control is also less precise, often leading to temperature gradients and potential contamination from fuel byproducts.

How Induction Furnaces Work (Direct Heat)

Induction furnaces operate on the principle of electromagnetic induction. A high-frequency alternating current is passed through a copper coil, which creates a powerful, rapidly changing magnetic field within the furnace chamber.

This magnetic field penetrates the conductive metal placed inside the coil, inducing electrical currents (known as eddy currents) within the metal itself. The metal's natural resistance to these currents generates intense heat from the inside out. It is a non-contact process where the metal becomes its own heating element.

Key Operational Advantages Explained

This shift to direct, internal heating creates a cascade of tangible benefits that directly impact throughput, cost, quality, and safety.

Unmatched Speed and Throughput

Because heat is generated instantly within the charge material, melting times are dramatically reduced. There is no need to preheat a large chamber or wait for thermal energy to slowly transfer from an external source. This allows for faster startup, quicker turnaround between melts, and significantly higher operational throughput.

Superior Energy Efficiency

Induction heating is remarkably energy-efficient. Almost all the electrical energy is converted directly into heat within the metal, with very little waste. Traditional methods lose a vast amount of energy to the environment. In vacuum induction models, a vacuum acts as a perfect insulator, further minimizing heat loss and reducing overall energy consumption.

Higher Purity and Quality Control

The non-contact nature of induction heating is critical for quality. The metal never touches a heating element or fuel source, which eliminates contamination that is common in traditional smelting.

Furthermore, the electromagnetic forces naturally stir the molten bath, ensuring a uniform temperature and a homogeneous chemical composition. This precision allows operators to meet exacting metallurgical specifications with high repeatability.

Enhanced Workplace Safety

Induction furnaces create a safer operating environment. The design eliminates the primary hazards of traditional smelting, such as open flames, explosive fuels, and intense radiated heat from external sources. The heat is contained within the metal itself, making the surrounding equipment cooler and the process far less hazardous for personnel.

Understanding the Trade-offs

While operationally superior in many ways, induction technology is not without its considerations. A balanced assessment requires acknowledging its specific requirements.

Higher Initial Capital Cost

The primary drawback is the higher initial investment. The power supplies, high-frequency electronics, and precision-engineered copper coils make induction furnaces more expensive to purchase and install than many simpler, traditional furnace types.

Material and Process Limitations

Induction heating works only on electrically conductive materials. While this covers most metals, it is a key limitation. Additionally, the efficiency of the process can be sensitive to the size, shape, and placement of the material within the coil, requiring more careful charge management.

Maintenance and Expertise

The sophisticated power electronics and water-cooling systems that support an induction furnace require a higher level of technical expertise to maintain and troubleshoot compared to the more mechanical nature of older furnace technologies.

Making the Right Choice for Your Goal

The decision between induction and traditional methods ultimately depends on your operation's primary strategic priorities.

- If your primary focus is maximizing throughput and speed: The rapid, on-demand heating of an induction furnace offers a clear advantage for high-volume production.

- If your primary focus is achieving the highest material purity: The non-contact, controllable nature of induction heating, especially in a vacuum, is unparalleled for producing clean, high-specification alloys.

- If your primary focus is minimizing long-term operational costs: The superior energy efficiency of induction will generate significant savings that can offset the higher initial capital investment over the furnace's lifespan.

- If your primary focus is on a low initial investment for basic melting: Traditional furnaces may remain a viable option, particularly where metallurgical precision and energy costs are less critical.

Choosing the right technology is a strategic investment in the quality of your product and the efficiency of your entire operation.

Summary Table:

| Advantage | Description |

|---|---|

| Speed | Dramatically reduced melting times and higher throughput due to direct internal heating. |

| Energy Efficiency | Superior energy use with minimal waste, as heat is generated directly in the metal. |

| Quality Control | Non-contact heating prevents contamination and ensures uniform, high-purity melts. |

| Safety | Eliminates open flames and reduces hazards, creating a safer work environment. |

| Initial Cost | Higher capital investment required compared to traditional methods. |

| Material Limitations | Only effective on electrically conductive materials like metals. |

Ready to upgrade your smelting process with advanced induction furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-performance furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering faster melting, higher purity, and cost savings. Contact us today to discuss how we can enhance your operational efficiency and safety!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications