In modern dental laboratories, furnaces are categorized primarily by the function they perform—firing, sintering, or pressing ceramic materials. While all are electrically powered and programmable, the key distinctions lie in their maximum temperature capabilities, their use of vacuum, and whether they include a mechanical pressing mechanism. These differences directly correspond to the types of restorations they are designed to create, from traditional porcelain-fused-to-metal (PFM) crowns to high-strength monolithic zirconia.

Your choice of furnace is not about selecting a generic "type," but about matching the equipment's core function—its temperature range and mechanical capabilities—to the specific requirements of the dental materials your lab works with.

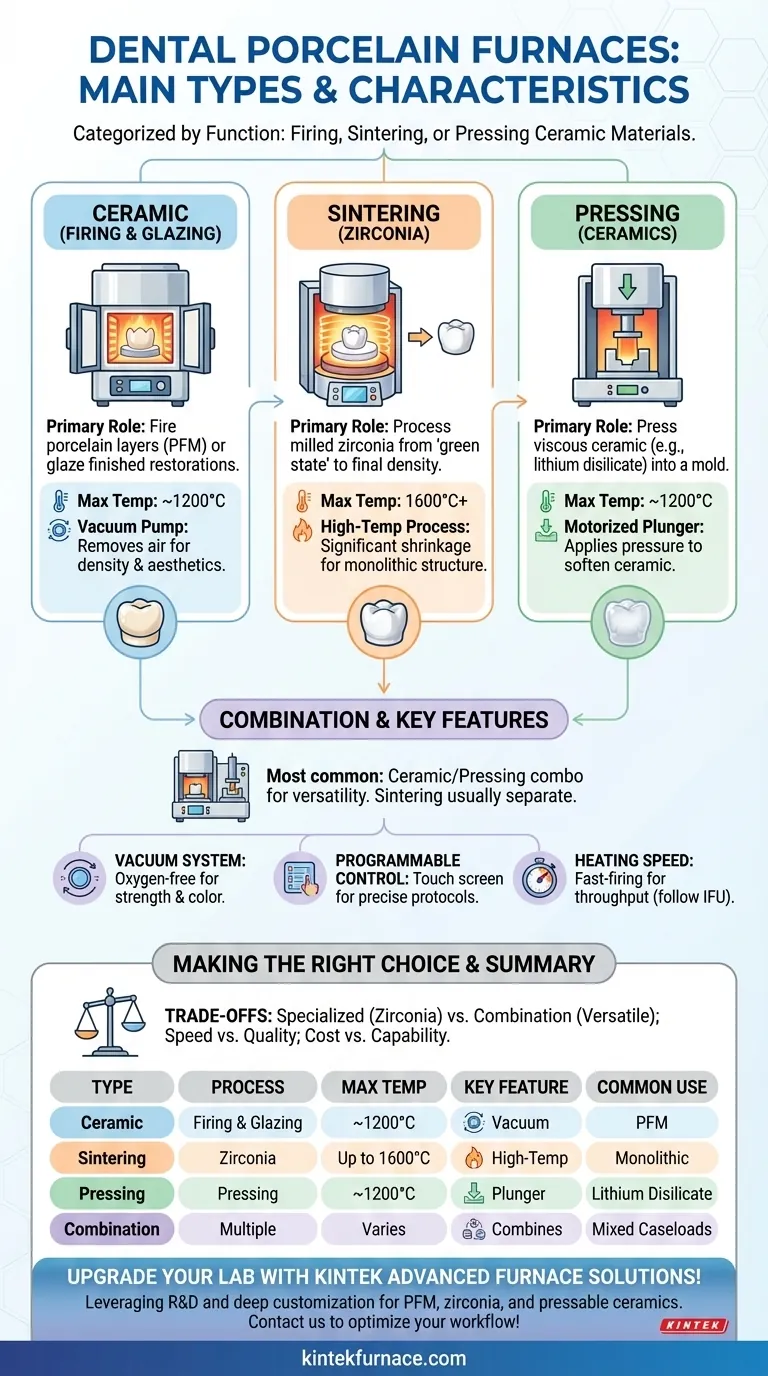

The Primary Furnace Categories by Process

The most accurate way to understand dental furnaces is to classify them by their primary technical process. Each category is designed to handle a specific class of dental materials.

Ceramic (Firing & Glazing) Furnaces

These are the traditional workhorses of the dental lab. Their primary role is to fire layers of porcelain onto a core or framework, such as in PFM crowns, or to glaze the surface of a finished restoration.

Key characteristics include a maximum temperature of around 1200°C and an integrated vacuum pump. The vacuum is critical for removing air during the firing cycle, which prevents porosity and results in a denser, stronger, and more aesthetic restoration.

Sintering Furnaces

These furnaces are purpose-built for one primary task: processing zirconia. After a zirconia restoration is milled from its soft, chalk-like "green state," it must be sintered at extremely high temperatures to achieve its final density and strength.

Sintering furnaces are defined by their ability to reach temperatures up to 1600°C or higher. This process causes the zirconia to shrink significantly—a factor that must be accounted for in the initial design—as the particles fuse together into a monolithic structure.

Pressing Furnaces

Pressing furnaces are designed for "pressable" ceramics, such as lithium disilicate (e.g., IPS e.max). The process involves heating a ceramic ingot until it becomes viscous and then mechanically "pressing" it into a void created within a specialized investment mold.

These units operate similarly to ceramic furnaces but include a motorized plunger that applies pressure to the softened ceramic. Most modern pressing furnaces can also function as standard ceramic furnaces, making them highly versatile.

Combination Furnaces

To maximize efficiency and footprint, many manufacturers offer combination units. The most common type is a Ceramic/Pressing combination furnace, which can handle both traditional porcelain firing/glazing and the pressing of materials like lithium disilicate. Sintering, however, almost always requires a separate, dedicated high-temperature unit.

Key Features That Define Performance

Beyond the primary category, several features differentiate modern furnaces and impact lab productivity and quality. These are not types of furnaces, but rather critical characteristics to evaluate.

The Vacuum System

A high-quality vacuum pump is non-negotiable for firing most porcelains. By creating an oxygen-free environment, it prevents discoloration and ensures the ceramic particles fuse without trapping gas bubbles, which would weaken the final restoration.

Programmability and Control

Virtually all modern furnaces are programmable, typically via a color touch screen. This allows technicians to create and store custom firing schedules with multiple stages of temperature, time, and vacuum. This precision is essential for following the specific protocols required by different ceramic manufacturers.

Heating Speed (Fast-Firing Capability)

Many furnaces now offer "fast-firing" cycles that significantly reduce processing time. While this boosts productivity for busy labs, it is a feature that must be used judiciously. The material being fired must be specifically approved for rapid heating to avoid thermal shock, which can cause cracking or incomplete vitrification.

Understanding the Trade-offs

Choosing the right equipment involves balancing cost, capability, and workflow.

Specialized vs. Combination Units

A dedicated sintering furnace is essential for any lab producing zirconia restorations. For other ceramics, a combination press/ceramic furnace offers excellent versatility and value for a lab handling a mixed caseload of PFM, veneers, and pressable crowns. A specialized, firing-only unit may be a cost-effective addition for high-volume glazing work.

Speed vs. Final Quality

Fast-firing cycles are a powerful tool for improving throughput, but they are not a substitute for proper technique. The manufacturer's instructions for use (IFU) for each ceramic material are the ultimate authority. Deviating from these protocols to save time can compromise the strength and aesthetics of the final restoration.

Cost vs. Required Capability

The investment correlates directly with capability. A basic ceramic furnace for glazing is the most affordable. A combination pressing furnace represents a moderate investment. A high-temperature sintering furnace is the most significant investment, justified only by a lab's commitment to producing zirconia restorations in-house.

Making the Right Choice for Your Lab

Base your decision on the types of restorations you produce most frequently.

- If your primary focus is PFM and layered ceramic crowns: A reliable ceramic furnace with precise vacuum control is your essential workhorse.

- If your primary focus is high-strength zirconia restorations: A dedicated high-temperature sintering furnace is a non-negotiable, foundational piece of equipment.

- If your primary focus is aesthetic pressable ceramics (e.g., e.max): A pressing furnace is required, and a combination press/ceramic unit provides the most operational flexibility.

- If you run a versatile, full-service digital lab: Your ideal setup likely includes both a high-temperature sintering furnace and a separate combination press/ceramic furnace to cover all material types.

Ultimately, the best furnace is the one that reliably and accurately executes the specific firing programs required by the materials you use every day.

Summary Table:

| Furnace Type | Primary Process | Max Temperature | Key Characteristics | Common Uses |

|---|---|---|---|---|

| Ceramic | Firing & Glazing | ~1200°C | Vacuum pump for porosity prevention | PFM crowns, glazing |

| Sintering | Zirconia processing | Up to 1600°C | High-temperature sintering for strength | Monolithic zirconia restorations |

| Pressing | Pressing ceramics | ~1200°C | Motorized plunger for pressure application | Lithium disilicate (e.g., IPS e.max) |

| Combination | Multiple processes | Varies | Combines ceramic and pressing functions | Versatile labs with mixed caseloads |

Upgrade your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're working with PFM, zirconia, or pressable ceramics, KINTEK ensures reliable performance and enhanced efficiency. Contact us today to discuss how our furnaces can optimize your workflow and deliver superior results for your target restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures