The primary benefits of an in-office ceramic furnace are a significant increase in clinical efficiency, direct control over aesthetic outcomes, and improved practice profitability. By bringing this capability in-house, you eliminate reliance on external labs for key finishing steps, allowing for faster treatment delivery and a higher degree of customization for porcelain restorations.

For a practice performing a significant volume of porcelain restorations, an in-office furnace shifts control from an external lab to your own hands. This transition directly translates to faster turnaround times, superior aesthetic customization, and a more streamlined, profitable workflow.

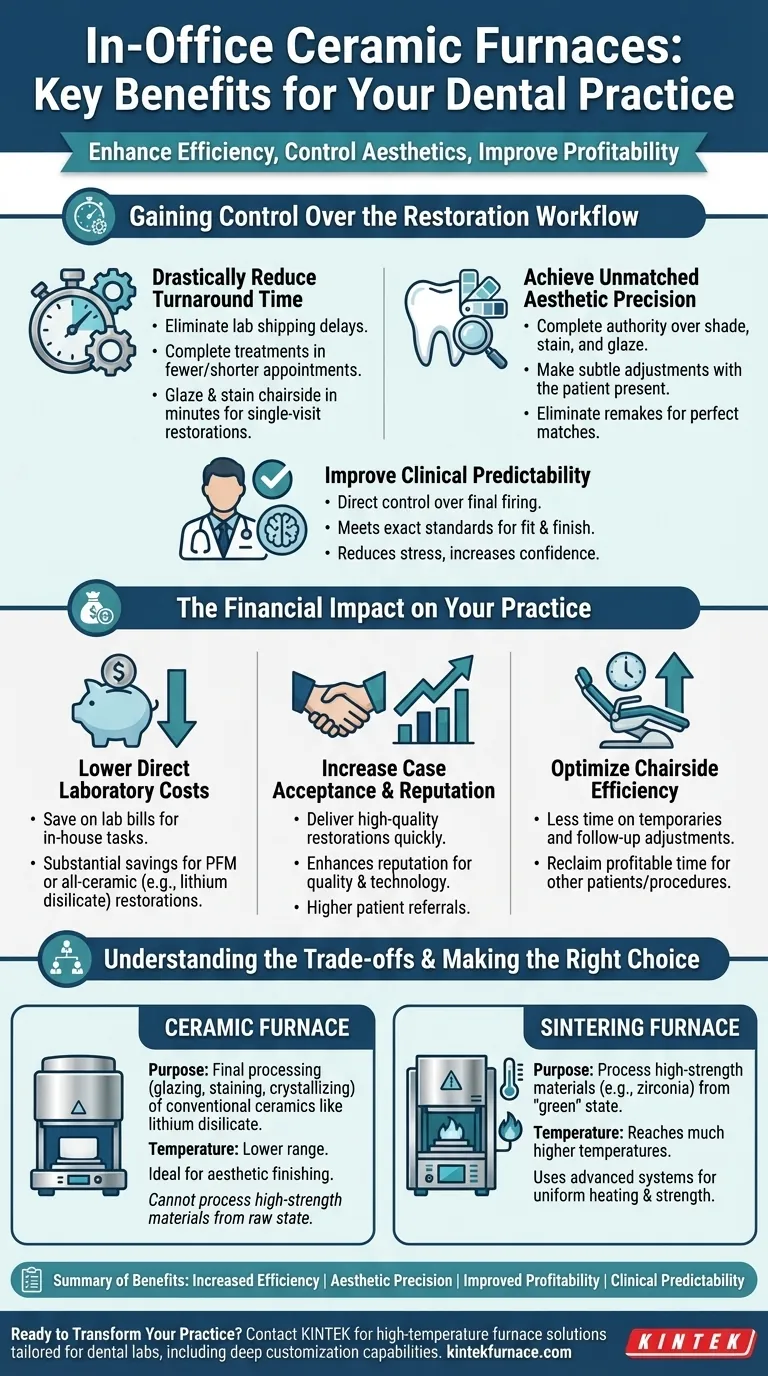

Gaining Control Over the Restoration Workflow

The most profound impact of an in-office furnace is the control it gives you over the timing, quality, and final look of your restorations. This eliminates the uncertainty and delays associated with external laboratory communication.

Drastically Reducing Turnaround Time

An in-office furnace removes the logistical delays of shipping cases to and from a lab. This allows you to complete treatments in fewer or shorter appointments.

For procedures like glazing and staining, what might take days with a lab can be done chairside in minutes. This makes single-visit restorations for certain cases a practical reality.

Achieving Unmatched Aesthetic Precision

Owning a furnace gives you complete authority over the final shade, stain, and glaze of a restoration. You can make subtle adjustments immediately with the patient present, ensuring a perfect match.

This ability to customize restorations on the spot eliminates frustrating remakes due to minor aesthetic mismatches, leading to higher patient satisfaction and predictable clinical results.

Improving Clinical Predictability

When you control the final firing process, you control the final outcome. You are no longer subject to a lab technician's interpretation of your prescription.

This direct oversight ensures that every restoration meets your exact standards for fit and finish, reducing stress and increasing your confidence in the final product.

The Financial Impact on Your Practice

Beyond clinical control, a ceramic furnace has a direct and positive effect on your practice's bottom line by reducing costs and creating new efficiencies.

Lowering Direct Laboratory Costs

Each time you use your in-office furnace for a task you would have outsourced, you are saving on a lab bill.

For practices that focus heavily on porcelain-fused-to-metal (PFM) or all-ceramic restorations like lithium disilicate, these savings can be substantial and lead to a quick return on the initial investment.

Increasing Case Acceptance and Reputation

The ability to deliver high-quality, perfectly matched restorations quickly becomes a powerful marketing tool. Patients value the convenience and superior results.

This enhances your practice's reputation for quality and technological advancement, which can lead to higher case acceptance and more patient referrals.

Optimizing Chairside Efficiency

Faster turnaround times mean less chair time is spent on temporary restorations and follow-up adjustment appointments.

This reclaimed time is more profitable, as it can be dedicated to seeing other patients or performing additional revenue-generating procedures.

Understanding the Trade-offs: Ceramic vs. Sintering Furnaces

It is critical to understand that not all furnaces are the same. The term "ceramic furnace" refers to a specific piece of equipment with a distinct purpose.

The Role of a Ceramic Furnace

A ceramic furnace is designed for the final processing of conventional dental ceramics. Its primary functions are glazing, staining, and crystallizing materials like lithium disilicate.

These furnaces use heating elements like Kanthal or Nichrome and operate at a lower temperature range, making them perfect for aesthetic finishing but unsuitable for processing high-strength materials from their raw state.

The Role of a Sintering Furnace

A sintering furnace is a different class of equipment designed to process high-strength materials, most notably zirconia, from their pre-sintered or "green" state.

These furnaces reach much higher temperatures and use advanced, computerized systems to ensure uniform heating, which is essential to achieve the material's final strength and structural integrity.

Choosing the Right Tool for the Material

A ceramic furnace cannot perform the function of a sintering furnace, and vice versa. The choice depends entirely on the types of restorations you intend to fabricate in-house.

Making the Right Choice for Your Practice

Integrating a furnace is a strategic decision that should align with your clinical goals and practice model.

- If your primary focus is aesthetic control over crowns and veneers: An in-office ceramic furnace is an essential tool for glazing, staining, and final crystallization of materials like lithium disilicate.

- If your primary focus is fabricating high-strength zirconia restorations from scratch: You will need a sintering furnace, as a standard ceramic furnace cannot reach the required temperatures.

- If your primary focus is cost reduction: Analyze your recent lab bills to confirm you have a sufficient volume of porcelain-based cases to justify the initial investment in a ceramic furnace.

By understanding the specific role of a ceramic furnace, you can make a strategic investment that empowers your practice with greater control, efficiency, and clinical excellence.

Summary Table:

| Benefit | Description |

|---|---|

| Increased Efficiency | Faster turnaround times and reduced reliance on external labs for single-visit restorations. |

| Aesthetic Precision | Direct control over shade, stain, and glaze for perfect matches and higher patient satisfaction. |

| Improved Profitability | Lower lab costs, higher case acceptance, and optimized chairside time leading to quick ROI. |

| Clinical Predictability | Ensures restorations meet exact standards, reducing remakes and increasing confidence. |

Ready to transform your dental practice with advanced in-office solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique requirements for ceramic and sintering furnaces. Contact us today to enhance your clinical efficiency and profitability!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations