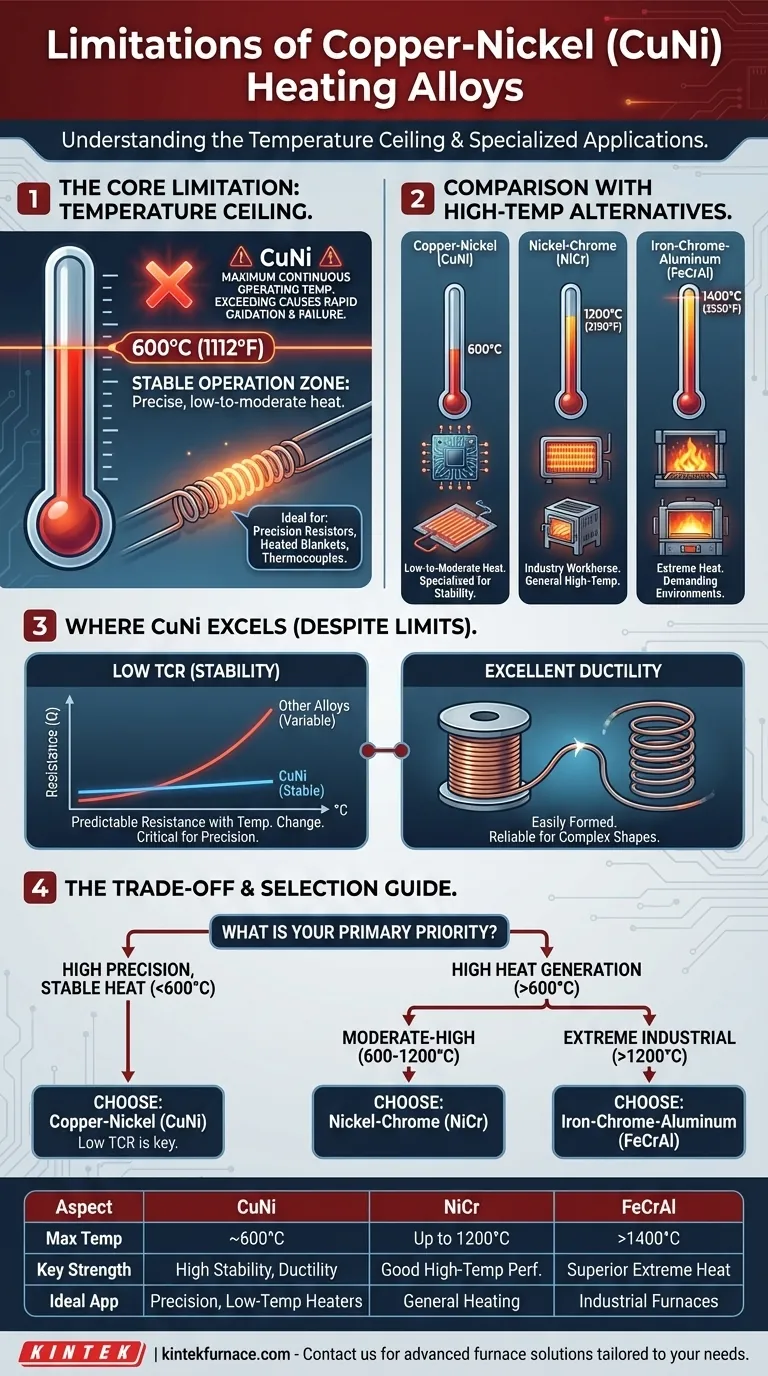

The primary limitation of Copper-Nickel (CuNi) alloys for heating applications is their relatively low maximum operating temperature. While valued for their stability and ductility, they cannot be used for continuous operation above 600°C (1112°F), which is significantly lower than the temperatures handled by other common resistance alloys.

The choice of a heating alloy is dictated by its intended operating temperature. Copper-Nickel is the superior choice for precise, low-to-moderate heat applications, while high-temperature tasks demand materials like Nickel-Chrome or Iron-Chrome-Aluminum.

The Core Limitation: Temperature Ceiling

The defining factor when selecting a resistance heating alloy is its ability to withstand its own generated heat without degrading. For CuNi, this creates a clear operational boundary.

The 600°C Boundary

Copper-Nickel alloys, such as Constantan (CuNi44), are limited to a maximum continuous operating temperature of approximately 600°C.

Exceeding this temperature causes the alloy to oxidize rapidly, leading to a change in resistance, mechanical weakness, and eventual element failure.

Comparison with High-Temperature Alternatives

To understand this limitation, it's crucial to compare it to other standard heating alloys.

- Nickel-Chrome (NiCr) alloys: These are the workhorses for many heating applications and can operate continuously at temperatures up to 1200°C (2190°F).

- Iron-Chrome-Aluminum (FeCrAl) alloys: These are designed for the most demanding high-temperature environments, such as industrial furnaces, and can operate at temperatures exceeding 1400°C (2550°F).

This stark difference means CuNi is fundamentally unsuitable for applications like kilns, furnaces, or high-power space heaters.

Where Copper-Nickel Excels Despite its Limits

The temperature limitation does not make CuNi an inferior alloy; it makes it a specialized one. Its unique properties make it the ideal choice for specific low-to-moderate temperature applications.

Unmatched Resistance Stability

The most significant advantage of CuNi is its extremely low Temperature Coefficient of Resistance (TCR).

This means its electrical resistance remains very stable and predictable even as its temperature changes. This is critical for applications requiring precise thermal control, such as precision resistors, thermocouples, and heating cables for sensitive processes.

Excellent Ductility and Formability

CuNi alloys are highly ductile, meaning they can be easily drawn into fine wires and formed into complex shapes without breaking.

This makes manufacturing easier and more reliable for components like heated blankets, underfloor heating mats, or custom-shaped low-temperature heaters.

Understanding the Trade-offs

Choosing a heating material is an exercise in balancing engineering trade-offs. The decision between CuNi and a higher-temperature alloy comes down to prioritizing either precision or heat capacity.

Precision vs. High Heat

The fundamental trade-off is clear:

- Choose Copper-Nickel when you need exceptionally stable, predictable, and repeatable heat output below 600°C.

- Choose Nickel-Chrome or FeCrAl when the primary goal is to generate high temperatures, and minor fluctuations in resistance are acceptable.

The Risk of Misapplication

Using a CuNi alloy in a high-temperature application is not a matter of reduced efficiency; it is a guarantee of premature failure.

The protective oxide layer that forms on heating alloys is stable on NiCr and FeCrAl at high temperatures, but it breaks down on CuNi, leaving the element vulnerable to rapid burnout.

Cost and Specification

Using a high-temperature alloy like FeCrAl for a low-temperature application (e.g., 200°C) is often unnecessary and not cost-effective. Matching the alloy to the specific temperature range of the application is the most efficient engineering practice.

Selecting the Right Alloy for Your Application

Your choice must be driven by the primary requirement of your heating element. Use these guidelines to make a definitive decision.

- If your primary focus is high-precision, stable heat below 600°C: Copper-Nickel is the correct and often superior choice due to its low TCR.

- If your primary focus is generating temperatures between 600°C and 1200°C: A Nickel-Chrome (NiCr) alloy is the industry standard and the appropriate selection.

- If your primary focus is extreme industrial heat above 1200°C: You must use an Iron-Chrome-Aluminum (FeCrAl) alloy to ensure element longevity.

By understanding these distinct operational boundaries, you can confidently select the right material for the job.

Summary Table:

| Aspect | Copper-Nickel (CuNi) | Nickel-Chrome (NiCr) | Iron-Chrome-Aluminum (FeCrAl) |

|---|---|---|---|

| Max Continuous Operating Temperature | ~600°C (1112°F) | Up to 1200°C (2190°F) | Exceeds 1400°C (2550°F) |

| Key Strengths | High resistance stability (low TCR), excellent ductility | Good high-temperature performance, widely used | Superior for extreme heat, durable in industrial settings |

| Ideal Applications | Precision resistors, thermocouples, low-temperature heaters | General heating elements, moderate to high temperatures | Industrial furnaces, high-power heating systems |

Struggling to choose the right heating alloy for your lab's specific temperature needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique requirements. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to ensure precise performance. Whether you need stable low-temperature precision or robust high-heat handling, we can help optimize your setup. Contact us today to discuss how our solutions can enhance your laboratory's efficiency and reliability!

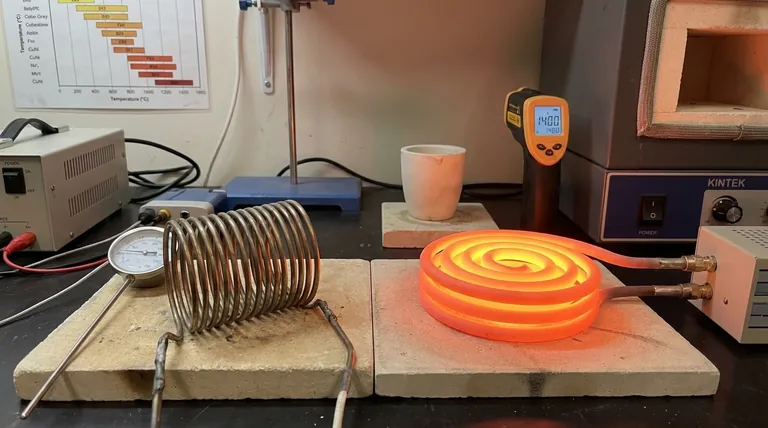

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element