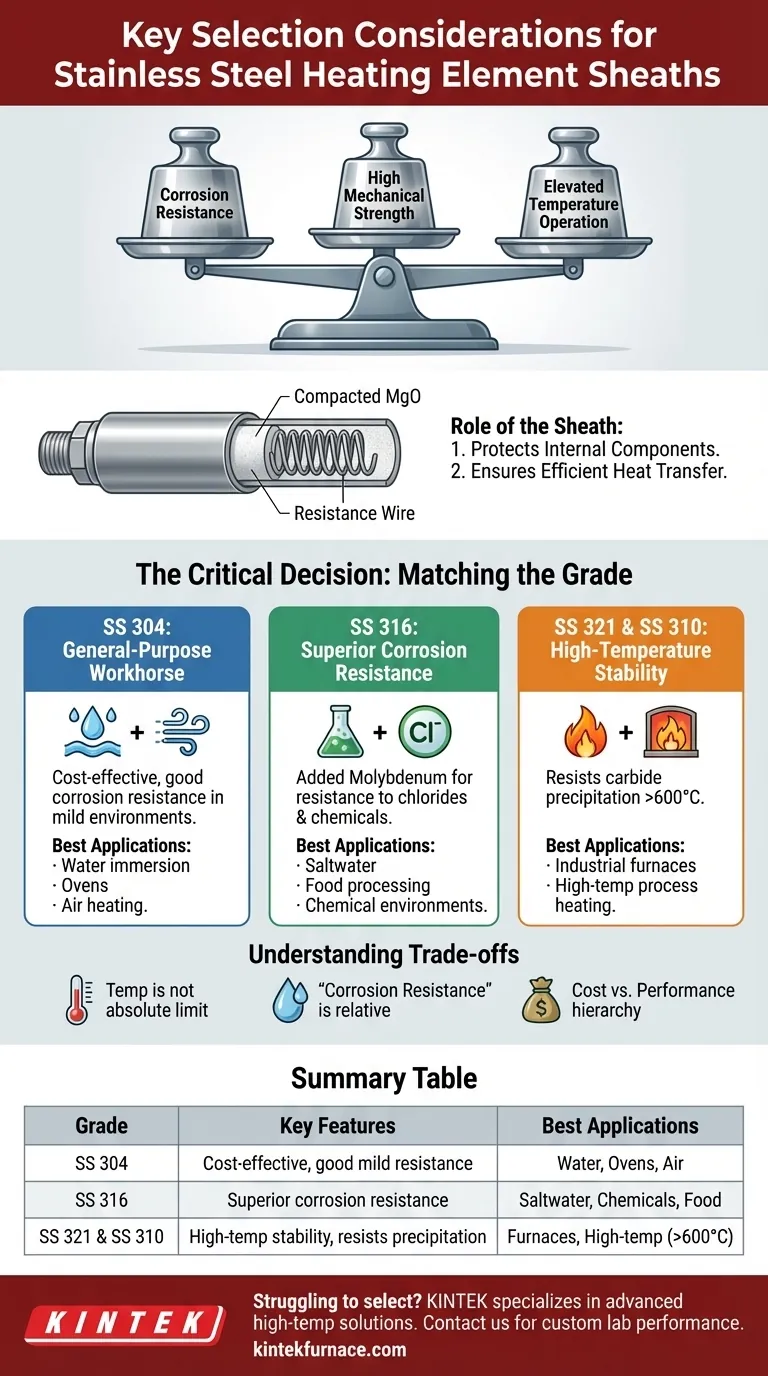

The primary considerations for selecting stainless steel as a heating element sheath are its excellent balance of corrosion resistance, high mechanical strength, and ability to operate at elevated temperatures. Its versatility makes it a default choice for applications ranging from heating water and air to use in mildly corrosive industrial environments.

The critical decision is not simply choosing stainless steel, but selecting the correct grade of stainless steel. Each grade offers a specific trade-off between cost, corrosion resistance, and high-temperature performance, and matching the grade to your operating environment is essential for longevity and safety.

The Role of the Sheath Material

A heating element sheath does not generate heat; its job is to protect the internal resistance wire (typically Nichrome) and the compacted magnesium oxide (MgO) insulation from the outside world.

Protection is the Priority

The sheath is the first line of defense against mechanical damage and environmental attack. A breach in the sheath leads to rapid element failure, as moisture or contaminants will compromise the insulation and short-circuit the resistance wire.

Ensuring Efficient Heat Transfer

The sheath material must also conduct heat efficiently from the internal wire to the surrounding medium (air, liquid, or a solid surface). Stainless steel provides good thermal conductivity for this purpose, though it is not as conductive as copper or aluminum.

Matching the Stainless Steel Grade to the Application

While often referred to as a single material, "stainless steel" is a family of alloys. The most common grades for heating element sheaths have distinct properties tailored for specific conditions.

SS 304: The General-Purpose Workhorse

SS 304 is the most widely used and cost-effective stainless steel. It offers excellent corrosion resistance in a wide range of atmospheric and fresh-water environments.

It is the standard choice for water immersion heaters, ovens, and air heating elements where the primary concerns are oxidation and general durability.

SS 316: Superior Corrosion Resistance

SS 316 contains an important addition: molybdenum. This element significantly enhances its resistance to corrosion from chlorides and other industrial chemicals.

Choose SS 316 for applications involving salt water, de-icing solutions, food processing environments with harsh cleaning agents, or certain acidic conditions. It is a necessary upgrade over SS 304 in these environments.

SS 321 & SS 310: High-Temperature Stability

When operating temperatures consistently exceed 500-600°C, standard stainless grades can suffer from a phenomenon called carbide precipitation. This depletes the chromium at the grain boundaries, making the steel susceptible to corrosion after it cools.

SS 321 (stabilized with titanium) and SS 310 (with high chromium and nickel content) are designed to resist this effect. They maintain their corrosion resistance and structural integrity at continuous high temperatures, approaching the 800°C maximum mentioned for specialty applications like industrial furnaces and high-temperature process heating.

Understanding the Trade-offs

Selecting the right material requires acknowledging its limitations. No single grade is perfect for every situation.

Temperature is Not an Absolute Limit

The maximum operating temperature of 800°C applies only to high-temperature grades like SS 310. For the common SS 304, the practical continuous operating temperature is much lower to avoid oxidation and loss of strength. Always consult the manufacturer's specifications for the specific element.

"Corrosion Resistance" is Relative

A material is only "corrosion-resistant" in relation to a specific substance. SS 304 is robust in fresh water but will fail quickly in a chloride-rich environment. Understanding the precise chemical makeup of the medium you are heating is non-negotiable.

Cost vs. Performance

There is a clear cost hierarchy. SS 304 is the baseline. SS 316 is more expensive due to the addition of molybdenum. High-temperature grades like SS 321 and SS 310 carry a significant cost premium for their specialized performance. Over-specifying a material leads to unnecessary expense.

Making the Right Choice for Your Goal

Base your selection on the most demanding aspect of your operating environment.

- If your primary focus is general-purpose heating (air, fresh water, mild foods): SS 304 offers the best balance of performance and cost.

- If your primary focus is resistance to specific corrosives (saltwater, chemicals, process fluids): SS 316 is the necessary and correct choice to prevent premature failure.

- If your primary focus is high-temperature operation (above 600°C): You must specify a stabilized grade like SS 321 or a high-alloy grade like SS 310 to ensure element longevity.

Ultimately, a successful design depends on accurately matching the sheath material's capabilities to the specific demands of the application.

Summary Table:

| Stainless Steel Grade | Key Features | Best Applications |

|---|---|---|

| SS 304 | Cost-effective, good corrosion resistance in mild environments | Water immersion heaters, ovens, air heating elements |

| SS 316 | Superior corrosion resistance to chlorides and chemicals | Salt water, food processing, industrial chemical environments |

| SS 321 & SS 310 | High-temperature stability, resists carbide precipitation | Industrial furnaces, high-temperature process heating above 600°C |

Struggling to select the right heating element sheath material for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your unique experimental needs, ensuring durability and efficiency in corrosive or high-heat environments. Contact us today to discuss how our tailored solutions can enhance your laboratory's performance and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance