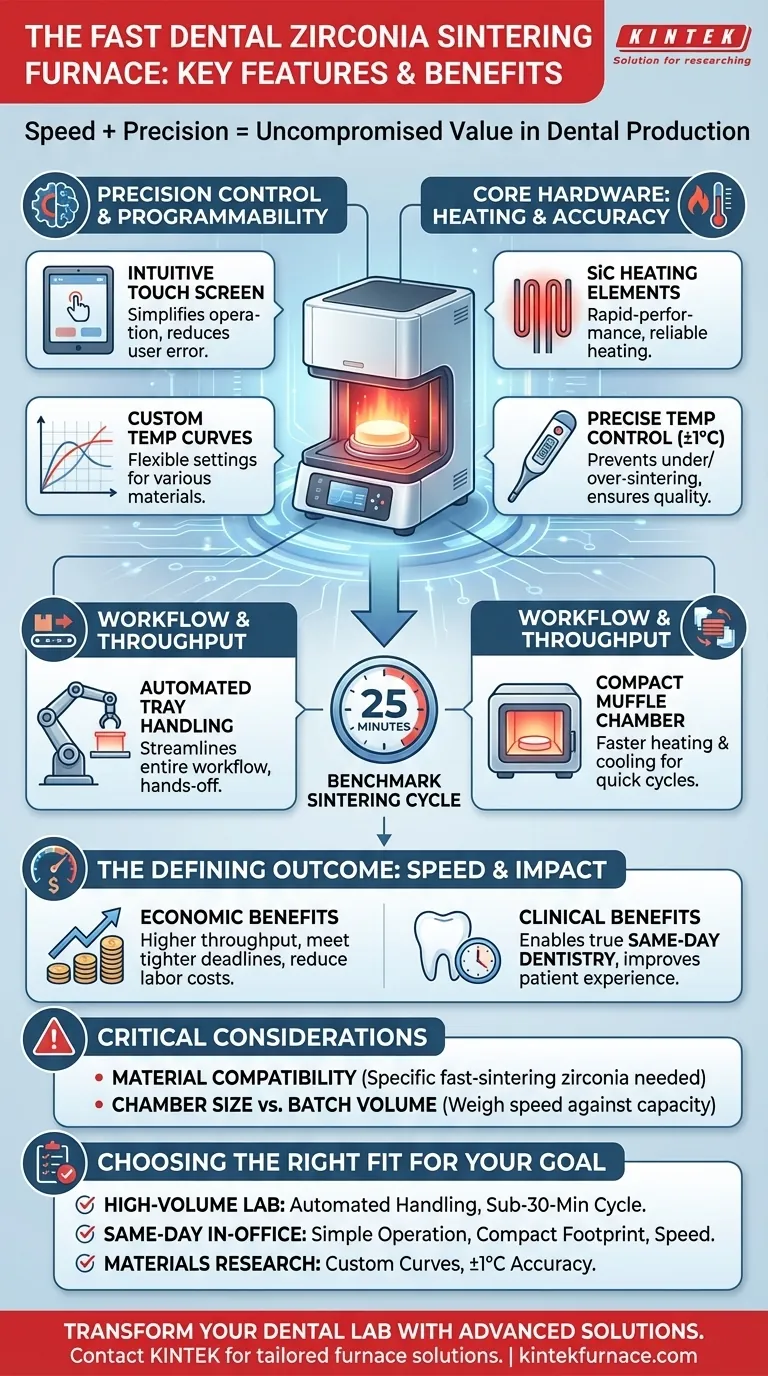

At its core, a fast dental zirconia sintering furnace is defined by its ability to drastically reduce processing time while maintaining precise control. Its key operational features include an intuitive touch screen interface, the ability to program custom temperature curves, rapid-performance heating elements, and automated tray handling that streamlines the entire workflow.

The true value of a fast sintering furnace lies not just in its speed, but in the combination of advanced hardware and software control that makes this speed achievable without compromising the structural integrity or esthetics of the final zirconia restoration.

The Anatomy of Rapid Sintering Performance

To achieve its signature speed, a fast sintering furnace integrates several key technologies. Each component is optimized to heat, hold, and cool the zirconia restorations within a tightly controlled and repeatable process.

Precision Control and Programmability

The furnace's "brain" is its control system. A modern touch screen interface simplifies operation, reducing the learning curve and minimizing the chance of user error.

Crucially, the furnace provides flexible temperature curve settings. This allows technicians to program unique heating and cooling rates (ramps) and holding times, ensuring the furnace can be calibrated to the specific requirements of various zirconia materials from different manufacturers.

The Core Hardware: Heating and Accuracy

The heart of the furnace is its muffle chamber and heating elements. High-performance furnaces typically use silicon carbide (SiC) heating elements, which are capable of reaching target temperatures very quickly and reliably.

This is paired with extremely precise temperature control, often with an accuracy of ±1°C. This precision is non-negotiable; it prevents under-sintering (which results in a weak restoration) and over-sintering (which can affect shade and translucency).

Workflow and Throughput

Features like automated tray handling directly impact lab efficiency. The system automatically moves the tray into and out of the heating chamber, freeing up technician time and ensuring consistent, hands-off operation.

The compact muffle chamber is also a deliberate design choice. A smaller volume can be heated and cooled much more rapidly, which is fundamental to achieving a fast cycle time.

The Defining Outcome: Speed and Its Impact

The culmination of these features is a dramatic reduction in processing time, which has significant economic and clinical benefits.

The 25-Minute Sintering Cycle

The benchmark feature of these furnaces is the ability to complete a full sintering cycle in as little as 25 minutes. This is a profound improvement over traditional furnaces, which can take several hours.

Economic and Clinical Benefits

This speed directly shortens the production cycle. For dental labs, this means higher throughput and the ability to meet tighter deadlines.

For dental clinics with in-office labs, this speed is what enables true same-day dentistry, allowing a patient to be scanned, and the crown milled and sintered for final delivery in a single appointment. This reduces labor costs and dramatically improves the patient experience.

Understanding the Trade-offs and Limitations

While speed is the primary advantage, it's critical to understand the associated considerations to ensure optimal results.

Material Compatibility is Non-Negotiable

Fast sintering cycles are engineered for specific, compatible zirconia materials that are formulated to withstand rapid heating. Using a standard zirconia puck not designed for fast firing can induce thermal shock, leading to fractures or compromised strength. Always verify the manufacturer's sintering protocol.

Chamber Size vs. Batch Volume

The compact chamber that enables rapid heating inherently limits the number of restorations that can be processed in a single cycle. Labs must weigh the benefit of a faster cycle time against the need for larger batch capacity.

Making the Right Choice for Your Goal

Selecting the right features depends entirely on your primary application.

- If your primary focus is high-volume lab production: The automated handling and sub-30-minute cycle time are the most critical features for maximizing daily throughput.

- If your primary focus is same-day, in-office dentistry: The simple touch-screen operation, compact footprint, and sheer speed are the essential features for efficient clinical workflow.

- If your primary focus is materials research: The ability to program custom temperature curves and the guaranteed ±1°C accuracy are non-negotiable for achieving valid and repeatable experimental results.

Ultimately, these furnaces empower dental professionals to deliver high-quality restorations with an efficiency that was previously unattainable.

Summary Table:

| Feature | Description |

|---|---|

| Touch Screen Interface | Simplifies operation with intuitive controls, reducing user error and learning time. |

| Custom Temperature Curves | Allows programming of heating/cooling rates for compatibility with various zirconia materials. |

| Silicon Carbide Heating Elements | Enable rapid heating for quick cycle times, ensuring reliable performance. |

| ±1°C Temperature Control | Provides high precision to prevent under- or over-sintering, maintaining restoration quality. |

| Automated Tray Handling | Streamlines workflow by automatically moving trays, increasing efficiency and consistency. |

| Compact Muffle Chamber | Facilitates fast heating and cooling, supporting quick 25-minute sintering cycles. |

Ready to transform your dental lab with advanced sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for high-volume production, same-day dentistry, or materials research. Contact us today to discuss how our tailored furnace solutions can enhance your efficiency and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time