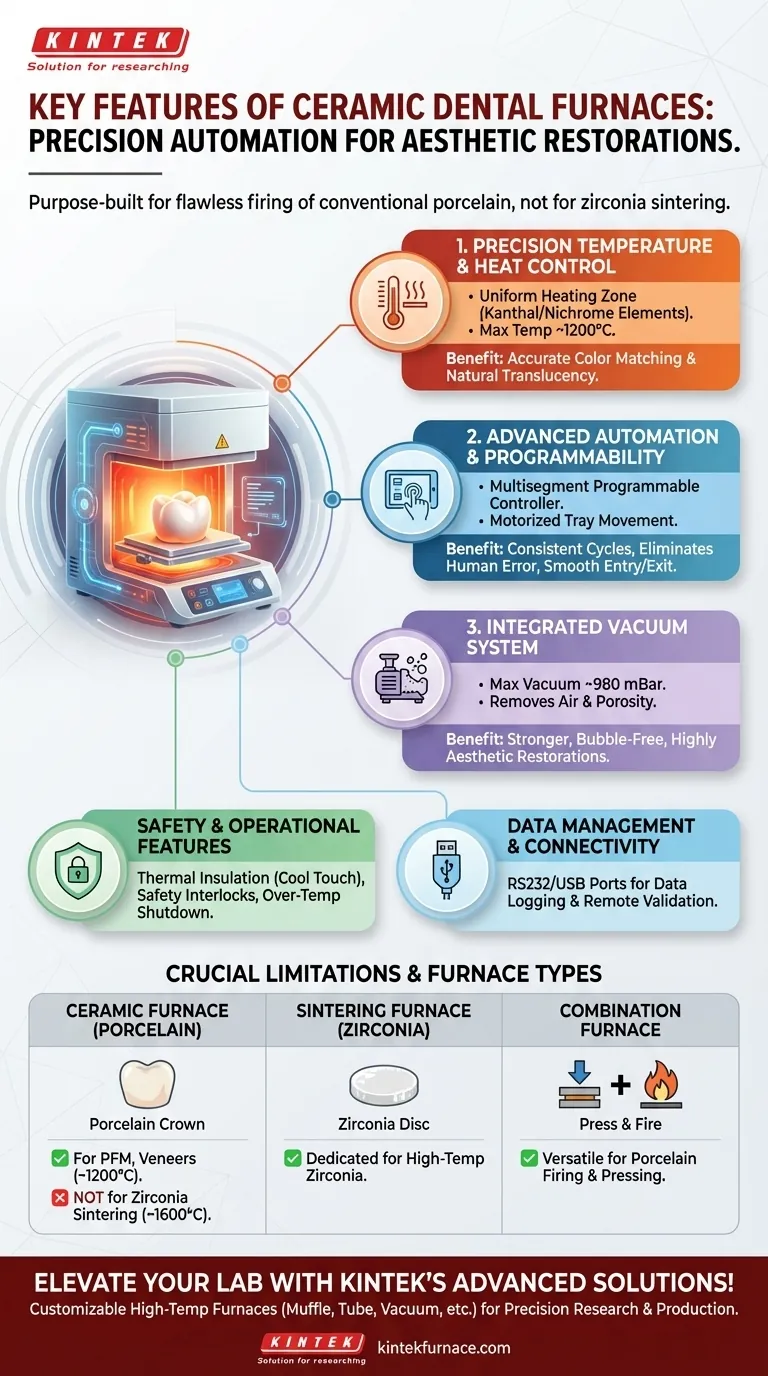

In essence, the key features of a ceramic dental furnace are centered on precision automation and control for aesthetic restorations. These furnaces are highly specialized tools equipped with programmable controllers, uniform heating zones, integrated vacuum systems, and advanced safety interlocks, all designed to flawlessly fire conventional dental ceramics like porcelain.

The core takeaway is that a ceramic furnace's features are purpose-built for one job: achieving perfect aesthetics in porcelain restorations. This specialization provides unmatched control over color and translucency but makes it fundamentally different from, and unsuitable for, the high-temperature sintering required for materials like zirconia.

The Core Function: Achieving Aesthetic Excellence

A ceramic furnace's primary role is to transform layered porcelain powder into a strong, lifelike dental restoration. Every feature is engineered to support this delicate process, where minor deviations can ruin the final result.

Precision Temperature and Heat Control

The most critical feature is the ability to manage heat with absolute accuracy. The furnace uses Kanthal or Nichrome heating elements to create a highly uniform heating zone, ensuring the entire restoration fires evenly.

This is managed by a controller that can reach a maximum temperature of around 1200°C. This level of thermal control is what allows technicians to precisely match color and achieve the natural translucency expected of high-quality crowns and veneers.

Advanced Automation and Programmability

Modern ceramic furnaces are fully automated to ensure consistency and eliminate human error. They feature a multisegment programmable controller, often operated via a color touch screen display.

Technicians can load specific firing programs for different types of porcelain. Features like precise, motorized tray movement ensure the restoration enters and exits the heat chamber smoothly, preventing thermal shock and cracks.

Integrated Vacuum System

To achieve maximum strength and density, the furnace incorporates a vacuum pump. During the firing cycle, the vacuum removes air trapped between porcelain particles.

This process eliminates porosity, resulting in a stronger, more aesthetic restoration free of bubbles or imperfections. A typical furnace can achieve a maximum vacuum of 980 mBar.

Essential Safety and Operational Features

Beyond the core firing process, these furnaces include features designed for operator safety, process validation, and long-term reliability.

Operator and Lab Safety

Safety is paramount. Furnaces are built with highly effective thermal insulation, which keeps the external surfaces cool to the touch and prevents heat loss, improving energy efficiency.

They also include critical safety interlocks that prevent the door from being opened during a high-temperature cycle. Added protections like over-temperature and over-current shutdown prevent damage to the unit and the restoration.

Data Management and Connectivity

For quality control and diagnostics, many furnaces offer modern connectivity options. Ports like RS 232/RS 485 or USB allow for remote connection and data logging.

This enables a lab to store and review temperature data for every cycle, ensuring processes are standardized and results are repeatable.

Understanding the Trade-offs and Limitations

While exceptional at their task, ceramic furnaces are not a one-size-fits-all solution. Understanding their limitations is crucial for any dental lab.

Material Specificity

These furnaces are designed exclusively for firing conventional dental ceramics. This includes porcelain-fused-to-metal (PFM) crowns, veneers, and certain types of all-ceramic crowns.

Unsuitability for High-Temperature Sintering

The most significant limitation is that a ceramic furnace cannot be used for sintering zirconia. Sintering is a different process that requires much higher temperatures (often up to 1600°C) to transform milled zirconia from a chalk-like state into its final, high-strength form.

The Role of Other Furnace Types

The dental field uses three main furnace types. A ceramic furnace is for firing porcelain. A sintering furnace is for zirconia. A combination furnace is a versatile unit that can handle both firing conventional porcelain and pressing ceramic materials.

Making the Right Choice for Your Lab

Selecting the right furnace depends entirely on the services your lab offers and the materials you work with most often.

- If your primary focus is aesthetic porcelain work (veneers, PFM): A dedicated ceramic furnace is the ideal tool, offering the highest level of precision for aesthetic outcomes.

- If your primary focus is high-strength zirconia restorations: You must invest in a high-temperature sintering furnace, as a ceramic furnace cannot perform this task.

- If your lab needs versatility for both pressing and firing ceramics: A combination furnace provides a cost-effective and space-saving solution to handle multiple restorative types.

Choosing the right tool is the first step toward delivering predictable, high-quality restorations for every case.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Precision Temperature Control | Uses Kanthal/Nichrome elements for uniform heating up to 1200°C | Ensures accurate color and translucency in restorations |

| Advanced Automation | Multisegment programmable controller with touch screen and motorized tray | Eliminates human error and ensures consistent firing cycles |

| Integrated Vacuum System | Achieves up to 980 mBar vacuum to remove air from porcelain | Increases strength and eliminates porosity for better aesthetics |

| Safety Features | Includes thermal insulation, safety interlocks, and over-temperature shutdown | Protects operators and prevents damage to restorations |

| Data Management | RS 232/RS 485 or USB ports for connectivity and data logging | Enables process validation and repeatable results |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you're focused on aesthetic porcelain work or need versatile solutions. Don't settle for less—contact us today to discuss how we can enhance your restoration processes and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision