At its core, a Chemical Vapor Deposition (CVD) furnace is a high-precision materials synthesis system. Its key features are not standalone components but an integrated set of controls designed for a single purpose: depositing a highly pure and uniform thin film onto a substrate. These defining features include a high-temperature reaction chamber, a precise gas delivery system, meticulous atmosphere and pressure control, and a robust exhaust management system.

A CVD furnace is not simply a high-temperature oven. Its defining features are all mechanisms of control, designed to manipulate gas-phase chemistry with extreme precision to grow a solid thin film with unparalleled purity and uniformity.

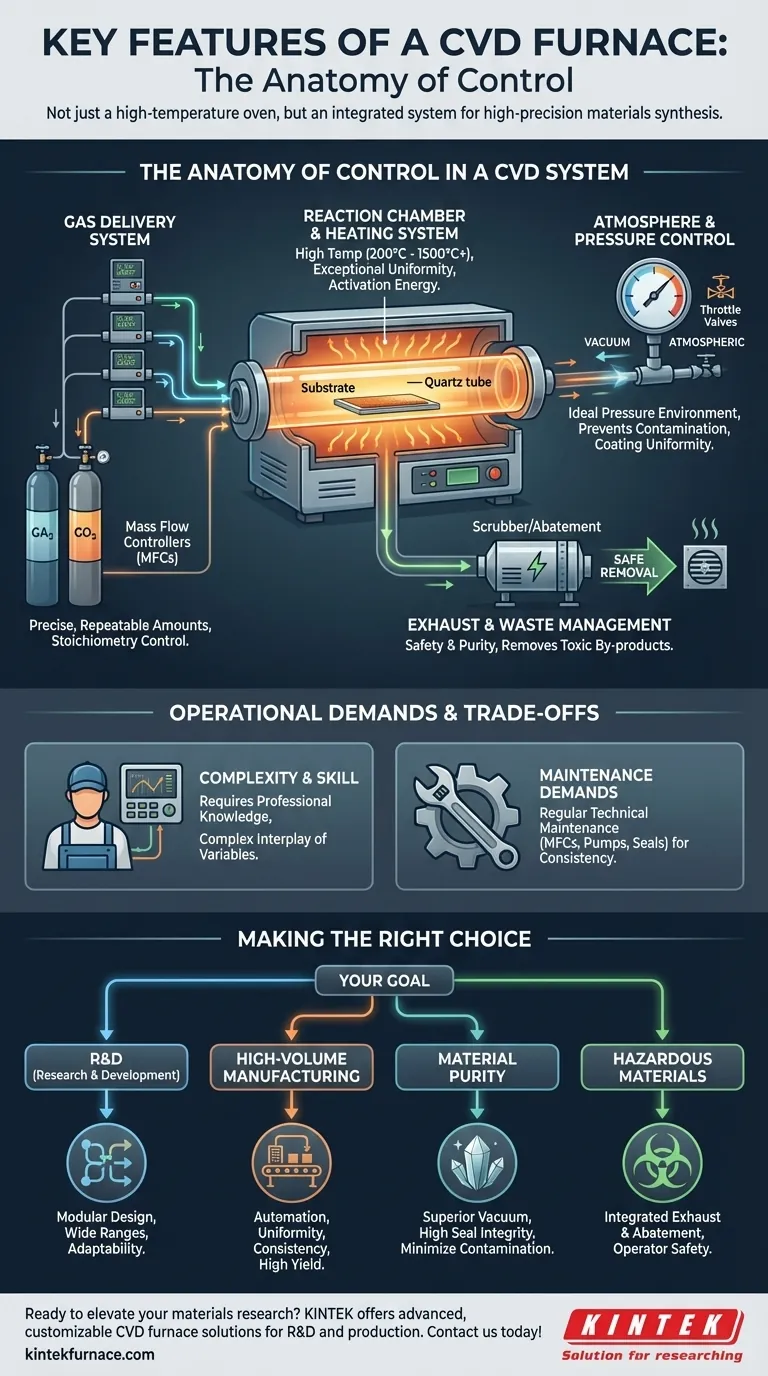

The Anatomy of Control in a CVD System

Understanding a CVD furnace requires looking beyond the heat and seeing it as an environment where every variable is deliberately managed. Each feature is a lever for controlling the outcome of the chemical reaction.

The Reaction Chamber and Heating System

The entire process happens within a chamber, typically a quartz tube, heated to temperatures ranging from 200°C to over 1500°C.

This high temperature provides the activation energy needed for the precursor gases to chemically react and form the solid film.

Crucially, the heating system is designed for exceptional temperature uniformity. Any "hot spots" or "cold spots" across the substrate would cause the film to grow at different rates, compromising its quality.

The Gas Delivery System

This is the heart of the furnace's precision. Gaseous precursors, the building blocks of the film, must be introduced into the chamber in exact, repeatable amounts.

This is accomplished using mass flow controllers (MFCs). These devices regulate the flow rate of each gas with incredible accuracy, ensuring the chemical reaction has the correct stoichiometry (the right ratio of reactants).

The precision of the gas delivery system directly dictates the deposition rate, chemical composition, and ultimate properties of the final material.

The Atmosphere and Pressure Control System

The environment inside the chamber is just as important as the temperature and gas flow. This system creates and maintains the ideal pressure for the deposition process.

Operations can occur at a vacuum (Low-Pressure CVD), atmospheric pressure (APCVD), or a precisely controlled low pressure.

Controlling the pressure prevents unwanted reactions with air (like oxidation) and manages the mean free path of gas molecules, which directly impacts the uniformity of the coating on the substrate surface. Throttle valves are often used to maintain this stable pressure environment.

The Exhaust and Waste Management System

The chemical reactions in a CVD process often produce toxic, corrosive, or flammable by-products, along with unreacted precursor gases.

An efficient exhaust system is critical for safety and process purity. It safely removes these waste gases from the chamber, often passing them through a scrubber or abatement system before venting.

This prevents harmful by-products from re-depositing onto the substrate, contaminating the film, or posing a hazard to operators and the environment.

Understanding the Trade-offs and Operational Demands

While powerful, CVD systems are not simple instruments. Their precision comes with inherent complexity and specific operational requirements.

Complexity and Skill Requirements

Operating a CVD furnace requires professional knowledge and skill. The interplay between temperature, pressure, and gas flow is complex, and improper operation can lead to poor results or safety hazards.

Unlike a standard tube furnace, a CVD system is a sophisticated piece of chemical processing equipment that demands a trained operator.

Maintenance Demands

The precise components, especially MFCs, vacuum pumps, and seals, require regular and technically demanding maintenance to ensure reliable performance.

Neglecting upkeep leads to inconsistent results, process drift, and ultimately, costly equipment failure. The maintenance costs and technical requirements are significantly higher than for simpler furnaces.

Lab vs. Production Considerations

For laboratory use, modularity and flexibility are often key. Researchers may need to swap out components or reconfigure the system for different experiments, prioritizing adaptability over throughput.

In a production environment, reliability, automation, and repeatability are paramount. The focus shifts to maximizing uptime and ensuring every run produces an identical result.

Making the Right Choice for Your Goal

The importance of each feature depends entirely on your end goal. When evaluating a CVD furnace, match its capabilities to your specific application.

- If your primary focus is research and development: Prioritize a modular design with flexible gas delivery and wide temperature and pressure ranges to accommodate diverse experiments.

- If your primary focus is high-volume manufacturing: Emphasize automation, robust process control software, and exceptional temperature uniformity to ensure product consistency and high yield.

- If your primary focus is material purity: Scrutinize the quality of the vacuum system and the integrity of all seals to minimize contamination from atmospheric leaks.

- If your primary focus is working with hazardous materials: Ensure the furnace has a state-of-the-art, fully integrated exhaust and abatement system to guarantee operator safety and environmental compliance.

Ultimately, the key features of a CVD furnace are purpose-built to transform volatile gases into a perfectly structured solid material.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| High-Temperature Reaction Chamber | Heated quartz tube for chemical reactions | Enables precise film deposition with uniform heating |

| Gas Delivery System | Uses mass flow controllers for exact gas flow | Ensures correct stoichiometry and deposition rate |

| Atmosphere and Pressure Control | Manages pressure (vacuum to atmospheric) | Prevents contamination and ensures coating uniformity |

| Exhaust and Waste Management | Removes toxic by-products safely | Enhances safety and process purity |

| Operational Demands | Requires skilled operation and maintenance | Demands training but offers high precision and reliability |

Ready to elevate your materials research with a custom CVD furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in R&D or production, we ensure reliability, purity, and efficiency. Contact us today to discuss how our CVD furnaces can drive your innovations forward!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision