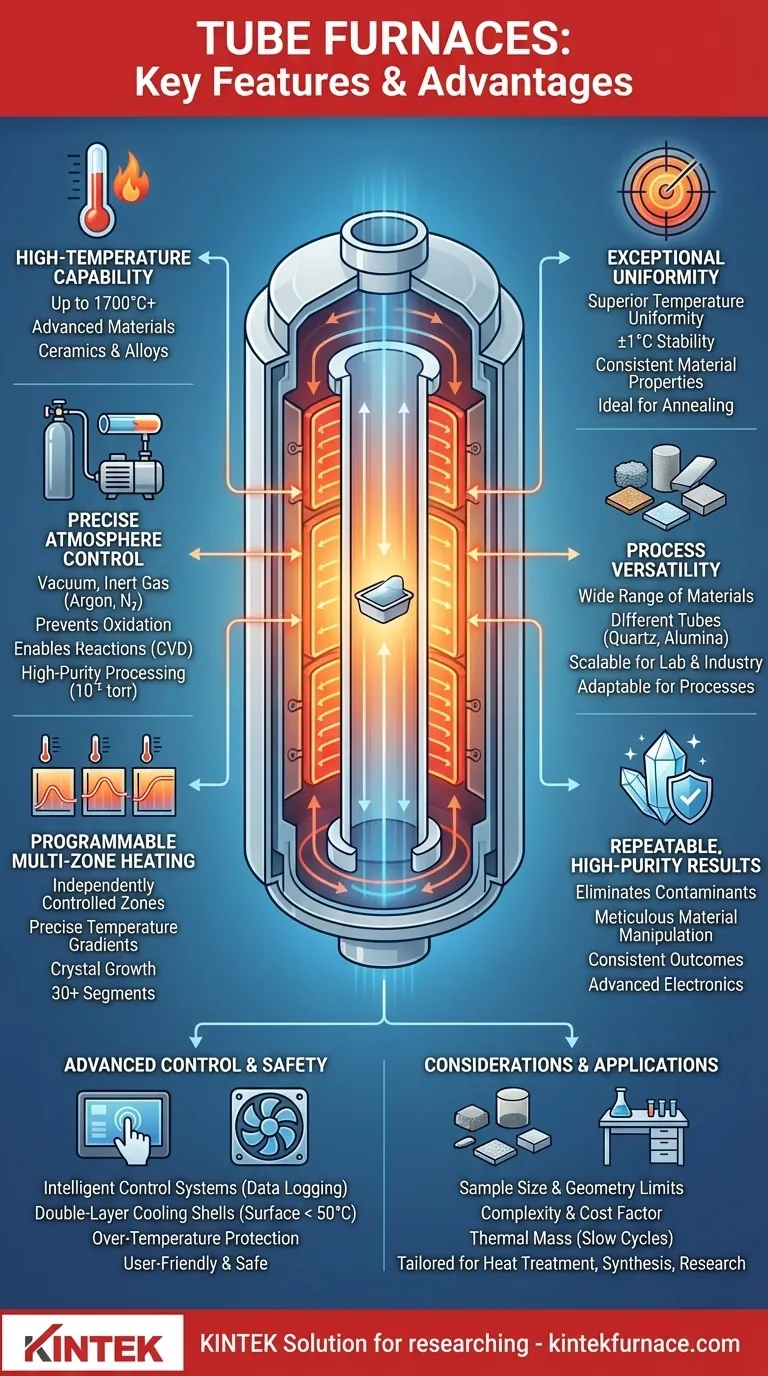

Fundamentally, a tube furnace offers unparalleled control over the thermal processing environment. Its key features include high-temperature capability (often exceeding 1700°C), precise multi-zone temperature regulation, and the ability to maintain a specific atmosphere, such as a vacuum or an inert gas. These features translate into the primary advantages of exceptional heating uniformity, process versatility for a wide range of materials, and repeatable, high-purity results.

A tube furnace should be viewed not merely as a high-temperature oven, but as a precision instrument. Its true value lies in its ability to meticulously manipulate material properties by creating a highly uniform, controllable, and isolated thermal environment.

The Core Principle: A Controlled Environment

A tube furnace is designed around a central ceramic or quartz tube that contains the sample. Heating elements surround this tube, creating a system that excels at delivering precise thermal energy in a tightly controlled atmosphere.

High-Temperature Capability

Tube furnaces are engineered to reach and sustain very high temperatures, with many models operating continuously up to 1700°C and reaching maximums of 1800°C or higher. This capability is essential for processing advanced materials like technical ceramics, alloys, and certain nanomaterials.

Unmatched Temperature Uniformity

The cylindrical design ensures that heat is radiated evenly from all sides toward the center of the tube. This results in superior temperature uniformity across the sample, a critical factor for processes like annealing, where consistent material properties are the primary goal. The temperature stability is often controlled to within ±1°C.

Precise Atmosphere Control

The enclosed tube is the furnace's defining feature, allowing for complete control over the gaseous environment. By connecting a vacuum pump or a gas delivery system, operators can run processes under specific conditions.

This is critical for:

- Preventing Oxidation: Using an inert gas like argon or nitrogen protects sensitive materials from reacting with oxygen at high temperatures.

- Enabling Reactions: Processes like Chemical Vapor Deposition (CVD) rely on introducing specific precursor gases into the hot zone to deposit thin films.

- High-Purity Processing: A vacuum can be used to remove atmospheric contaminants, with some systems achieving levels as low as 10⁻⁵ torr.

Advanced Control and Usability

Modern tube furnaces integrate sophisticated electronics and thoughtful design to enhance precision, repeatability, and ease of use.

Programmable, Multi-Zone Heating

Instead of a single heating zone, many furnaces feature multiple, independently controlled zones along the length of the tube. This allows for the creation of precise temperature gradients, which are essential for specialized applications like crystal growth or certain types of chemical transport reactions. Controllers often allow for 30 or more programmable segments to execute complex heating and cooling profiles automatically.

Intelligent Control Systems

Modern furnaces are equipped with user-friendly interfaces, such as color touchscreens and software for data logging. These systems reduce the risk of human error, ensure process repeatability, and allow for remote monitoring, which is invaluable for long-duration experiments or continuous production.

Versatility in Materials and Scale

The choice of tube material—typically quartz for lower temperatures (<1200°C) or alumina for higher temperatures—allows the furnace to be adapted for different chemical processes. While often used in labs, the design is scalable, and multiple tube furnaces can be integrated into larger industrial production lines.

Understanding the Trade-offs

While powerful, tube furnaces are a specialized tool with specific limitations that must be considered.

Sample Size and Geometry

The primary constraint is the diameter of the tube. This limits the size and shape of the samples that can be processed, making tube furnaces less suitable for bulky or irregularly shaped objects compared to a box or muffle furnace.

Complexity and Cost

Advanced features like multi-zone control, high-vacuum compatibility, and sophisticated gas mixing systems add significant complexity and cost. A basic single-zone furnace is far more affordable than a multi-zone CVD system.

Thermal Mass and Cycle Time

The ceramic insulation required for high-temperature stability gives the furnace significant thermal mass. This means that heating and, especially, cooling cycles can be slow. However, some designs feature a sliding or splitting mechanism to move the tube out of the heating zone for rapid cooling.

Built for Operator Safety

Operating at extreme temperatures requires a focus on safety. Tube furnaces incorporate key features to protect both the user and the lab environment.

Double-Layer Cooling Shells

Most modern furnaces feature a dual-layer steel housing with an internal cooling fan. This design actively dissipates heat, keeping the external surface temperature low—often below 50°C—even when the internal temperature is over 1000°C.

Over-Temperature Protection

Integrated safety circuits automatically shut down the furnace if the temperature exceeds a set limit, preventing damage to the equipment and the sample.

Making the Right Choice for Your Application

The ideal tube furnace configuration depends entirely on your specific process requirements.

- If your primary focus is heat treatment (annealing, sintering): Prioritize a furnace with documented, exceptional temperature uniformity across a long hot zone to ensure consistent results.

- If your primary focus is material synthesis (CVD, crystal growth): A multi-zone furnace is essential for creating precise temperature gradients, and a robust gas delivery and control system is non-negotiable.

- If your primary focus is general-purpose lab research: A versatile single-zone splitting tube furnace with interchangeable quartz and alumina tubes and basic vacuum/gas capabilities offers the most flexibility.

By understanding these core capabilities, you can confidently select a tube furnace that serves not just as a heat source, but as a precision instrument for achieving your goals.

Summary Table:

| Feature | Advantage |

|---|---|

| High-temperature capability (up to 1800°C) | Enables processing of advanced materials like ceramics and alloys |

| Precise multi-zone temperature control | Ensures uniform heating and repeatable results for annealing and sintering |

| Atmosphere control (vacuum, inert gas) | Prevents oxidation, supports high-purity processes like CVD |

| Scalable design and safety features | Adaptable for labs to production, with cooling shells and over-temperature protection |

Ready to elevate your lab's capabilities with a precision tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Contact us today via our contact form to discuss how we can help you achieve superior thermal processing results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis