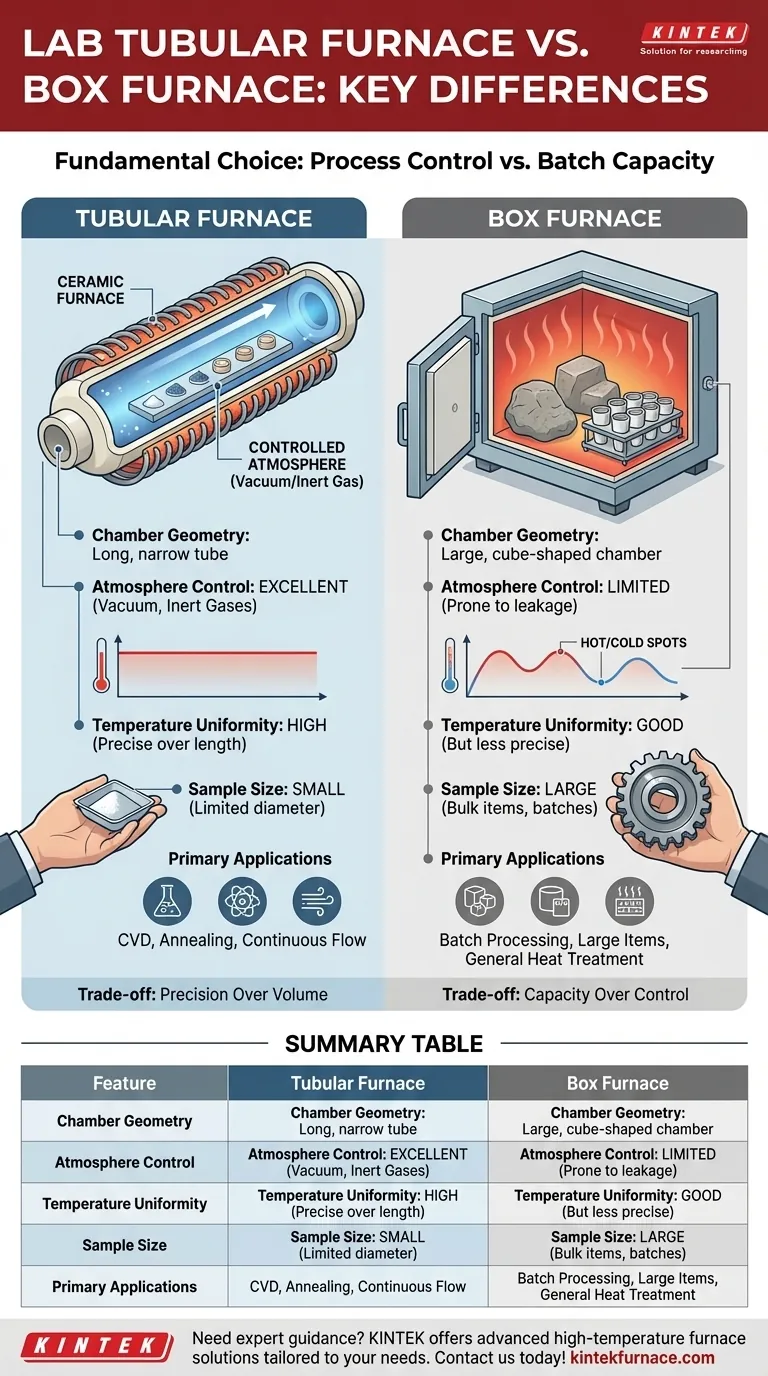

At their core, the key differences between a lab tubular furnace and a box furnace are their chamber geometry and the processing applications this geometry enables. A tubular furnace uses a long, narrow tube ideal for precise atmosphere control and temperature uniformity over a specific length, while a box furnace has a large, cube-shaped chamber designed for heating bigger items or multiple samples in a single batch.

The decision between these two furnace types is a fundamental choice between process control and batch capacity. A tube furnace offers unparalleled control over atmosphere and temperature for smaller samples, whereas a box furnace provides the volume needed for larger-scale heat treatment.

The Fundamental Design Difference: Chamber Geometry

The most significant distinction stems from the shape of the heating chamber itself. This single factor dictates how samples are heated, the atmospheres they can be subjected to, and their maximum size.

The Tubular Furnace: A Controlled Pathway

A tubular furnace is built around a long, cylindrical chamber, typically made of ceramic or quartz. Material is either placed inside this tube or passed through it.

This design is optimized for a linear process. Its small, enclosed volume makes it exceptionally well-suited for creating and maintaining a specific, high-purity atmosphere.

The Box Furnace: A Volumetric Chamber

A box furnace, often called a muffle furnace, features a large, front-loading chamber, much like a conventional oven. Its primary purpose is to heat one or more objects placed inside it.

This geometry is designed for batch processing. It accommodates larger, bulkier, or irregularly shaped items that simply would not fit inside a narrow tube.

Key Differentiators in Application

Understanding the design differences allows us to see how each furnace excels in different laboratory applications. The choice is rarely about which is "better" overall, but which is correct for a specific task.

Atmosphere Control and Purity

This is the defining advantage of a tube furnace. The ends of the tube can be sealed with flanges, allowing for the complete evacuation of air (vacuum) or the introduction of a controlled inert or reactive gas.

This capability is critical for processes like chemical vapor deposition (CVD), annealing sensitive materials, or growing crystals, where atmospheric oxygen would ruin the sample. Specialized cold-wall vacuum furnaces, which have water-cooled shells, offer even faster heating/cooling and higher purity.

A box furnace struggles to achieve this level of atmospheric purity due to the large door seal, which is a common point of leakage.

Temperature Uniformity

A tube furnace offers superior temperature uniformity along its heated length. This is especially true for three-zone models, which use independent controllers for the center and end zones to create a highly stable and consistent temperature profile.

This precision is vital for processes where every part of the sample must experience the exact same temperature. While box furnaces can achieve good uniformity, they are more prone to hot and cold spots, especially when fully loaded.

Sample Size and Throughput

This is the primary strength of a box furnace. Its large chamber is ideal for heat-treating many small parts at once, annealing large components, or ashing multiple crucibles simultaneously.

A tube furnace is inherently limited by its tube's inner diameter, which typically ranges from just 15 mm to 200 mm. It is designed for small coupons, powders, or a continuous flow of material, not large-scale batch work.

Understanding the Trade-offs

Choosing a furnace involves balancing its capabilities with its limitations. Both designs come with inherent compromises that you must consider for your application.

Tube Furnace: Precision Over Volume

The primary trade-off is sample size. You gain exceptional control over atmosphere and temperature at the cost of being severely restricted by the tube's diameter and length.

Accessibility can also be a factor. Solid tube models require you to slide samples in from the end, while split-tube furnaces hinge open, providing direct access to the sample, which can be a significant advantage.

Box Furnace: Capacity Over Control

The main compromise is atmosphere control. While some models offer ports for introducing gas, they cannot achieve the vacuum levels or purity of a sealed tube furnace.

Likewise, achieving perfect temperature uniformity across a large, open chamber is more challenging and often requires more complex and expensive models with forced air circulation.

Making the Right Choice for Your Process

Your specific experimental or production goal is the only factor that matters. By aligning your primary need with the furnace's core strength, you ensure you are acquiring the correct tool for the job.

- If your primary focus is controlled atmosphere processing (vacuum, inert gas) or exceptional temperature uniformity: A tube furnace is the superior and often only viable choice.

- If your primary focus is processing large samples, multiple samples at once, or general-purpose heat treatment: A box furnace provides the necessary capacity and simplicity.

- If your primary focus is continuous material synthesis, deposition, or zone refining: The linear pathway of a tube furnace is specifically designed for these flow-through processes.

Understanding these core design principles allows you to select a furnace not just as a tool, but as a precise instrument for achieving your specific scientific or industrial goals.

Summary Table:

| Feature | Tubular Furnace | Box Furnace |

|---|---|---|

| Chamber Geometry | Long, narrow tube | Large, cube-shaped chamber |

| Atmosphere Control | Excellent (vacuum, inert gases) | Limited (prone to leakage) |

| Temperature Uniformity | High, especially with multi-zone | Good, but prone to hot/cold spots |

| Sample Size | Small (limited by tube diameter) | Large or multiple samples |

| Primary Applications | CVD, annealing, continuous flow | Batch processing, large items |

Need expert guidance to select the perfect furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your process efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety