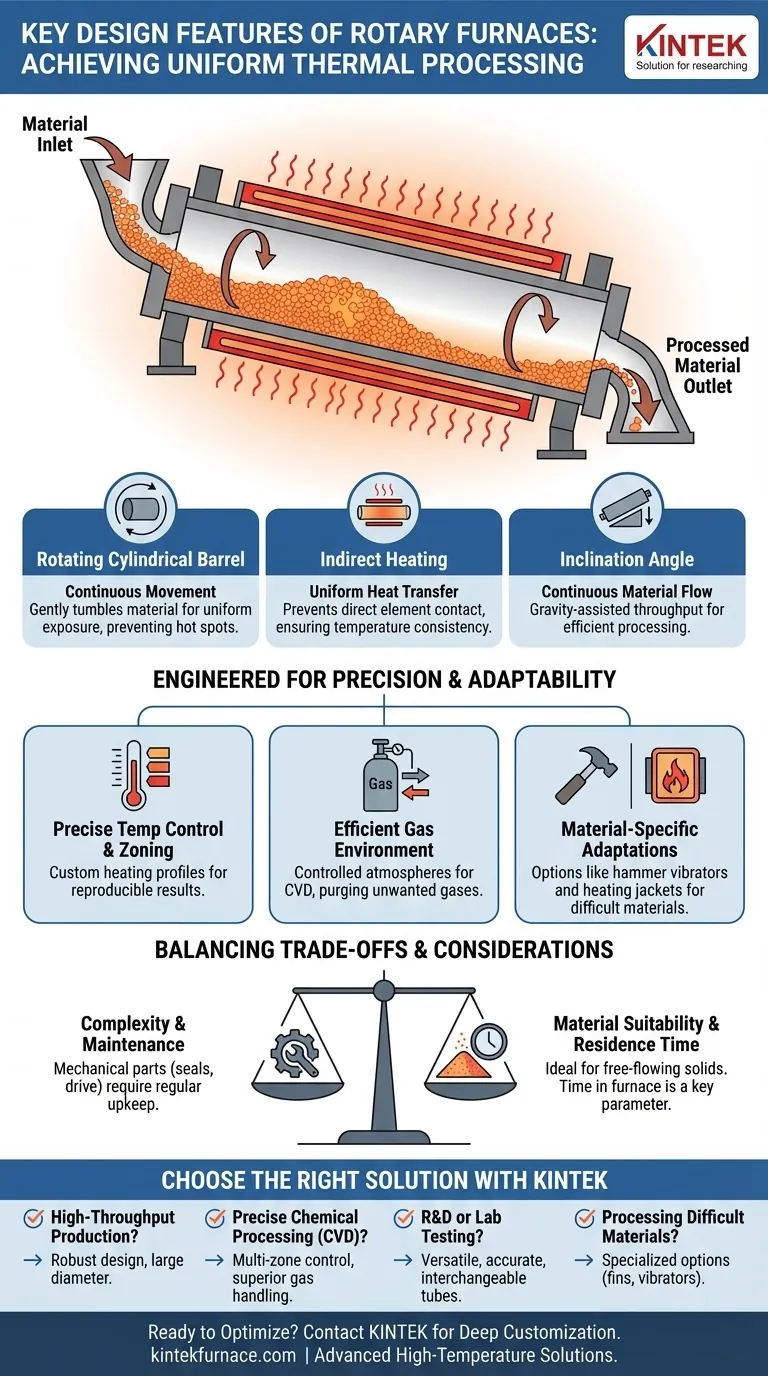

At its core, a rotary furnace is defined by its long, inclined cylindrical barrel that rotates slowly. This fundamental design ensures that the material inside is constantly in motion, guaranteeing continuous movement and exceptionally uniform exposure to heat. External heating elements provide the thermal energy, while the rotation ensures this energy is distributed consistently throughout the material being processed.

The design of a rotary furnace is a purpose-built system for achieving unparalleled thermal uniformity in loose materials. Its key features—rotation, inclination, and indirect heating—work in concert to solve the challenge of evenly processing powders, granules, or small solids in a continuous or batch-fed operation.

The Core Design Philosophy: Dynamic, Uniform Heating

The primary goal of a rotary furnace is to overcome the limitations of static heating, where material can have hot spots or unheated cores. Every major design feature serves this purpose.

The Rotating Cylindrical Barrel

The furnace's central component is a work tube or barrel, typically made of ceramic or metal alloy, that rotates on its longitudinal axis.

This slow, constant rotation gently tumbles the material inside. This action, often called "cascading," continuously exposes new surfaces of the material to the heated wall of the tube.

The Principle of Indirect Heating

Most rotary furnaces use indirect heating. The heating elements are positioned outside the rotating barrel, heating the barrel's surface first.

The barrel then transfers this heat to the material through conduction and radiation. This method prevents direct exposure of the material to the heating elements, which is critical for preventing overheating and ensuring temperature uniformity.

Continuous Material Flow

The barrel is set at a slight inclination angle. Gravity, combined with the rotational tumbling, causes the material to move steadily from the higher entry point to the lower exit point.

This design enables continuous processing, where new material is constantly fed into the furnace as processed material exits, making it highly efficient for high-throughput industrial applications.

Key Engineering Features and Their Purpose

Beyond the core principles, specific engineering features allow rotary furnaces to be adapted for highly specialized tasks.

Precise Temperature Control and Zoning

Modern rotary furnaces feature sophisticated control systems for precise temperature regulation. This ensures that experimental or production results are accurate and reproducible.

Many designs allow for customizable heating zones. This means different sections of the barrel's length can be held at different temperatures, creating a tailored heating profile as the material travels through the furnace.

Efficient Gas Environment Management

For applications like Chemical Vapor Deposition (CVD) or processes requiring an inert atmosphere, gas handling is critical.

These furnaces often include dedicated gas ports, such as a 1/4 inch inert gas inlet and a KF25 outgassing port. This allows for precise control of the internal atmosphere, purging unwanted gases and introducing specific process gases.

Material-Specific Adaptations

The versatility of rotary furnaces comes from their ability to be customized. For high-viscosity or sticky organic materials, an optional hammer vibrator can be added to prevent material from clumping or sticking to the tube walls.

For processes that produce condensable byproducts like tar, heating jackets can be fitted around the furnace ends to keep them hot and prevent condensation from blocking the system.

Understanding the Trade-offs

While highly effective, the rotary design introduces specific considerations that differ from static furnaces.

Mechanical Complexity

The rotating mechanism, including the drive motor, seals, and support rollers, adds mechanical complexity. These moving parts require regular maintenance to ensure reliability, particularly the seals which are critical for maintaining atmosphere integrity.

Material Suitability

Rotary furnaces are ideal for powders, granules, and small, free-flowing solids. They are not suitable for large, single components or delicate materials that could be damaged by the tumbling action.

Balancing Throughput and Residence Time

The time a material spends inside the furnace—its residence time—is a critical process parameter. This is controlled by a combination of the barrel's rotation speed and its inclination angle. A faster rotation or steeper angle will decrease residence time, increasing throughput but reducing the time for heat treatment.

Making the Right Choice for Your Goal

Selecting the correct features is essential for aligning the furnace's capabilities with your specific application.

- If your primary focus is high-throughput production: Prioritize a robust, continuous-feed design with a durable drive system and a large-diameter barrel.

- If your primary focus is precise chemical processing (like CVD): Emphasize multi-zone temperature control and a sophisticated gas handling system with high-integrity seals.

- If your primary focus is R&D or lab-scale testing: Choose a smaller, versatile model with highly accurate temperature controls and easily interchangeable work tubes for experimenting with different materials.

- If your primary focus is processing difficult materials: Investigate specialized options like internal fins, hammer vibrators, or specific tube materials designed to promote flow and prevent sticking.

By understanding these core design principles and available features, you can confidently specify a rotary furnace that precisely matches your material processing objectives.

Summary Table:

| Key Design Feature | Purpose |

|---|---|

| Rotating Cylindrical Barrel | Ensures continuous material movement and uniform heat exposure |

| Indirect Heating | Prevents overheating and guarantees temperature uniformity |

| Inclination Angle | Enables continuous material flow and processing efficiency |

| Multi-Zone Temperature Control | Allows tailored heating profiles for precise results |

| Gas Environment Management | Supports processes like CVD with controlled atmospheres |

| Material-Specific Adaptations | Prevents clumping and condensation for difficult materials |

Ready to optimize your material processing with a custom rotary furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-throughput production, precise chemical processing, or specialized R&D setups, we can design a furnace that enhances efficiency and accuracy. Contact us today to discuss your needs and discover how KINTEK can bring superior thermal processing to your lab or facility!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs