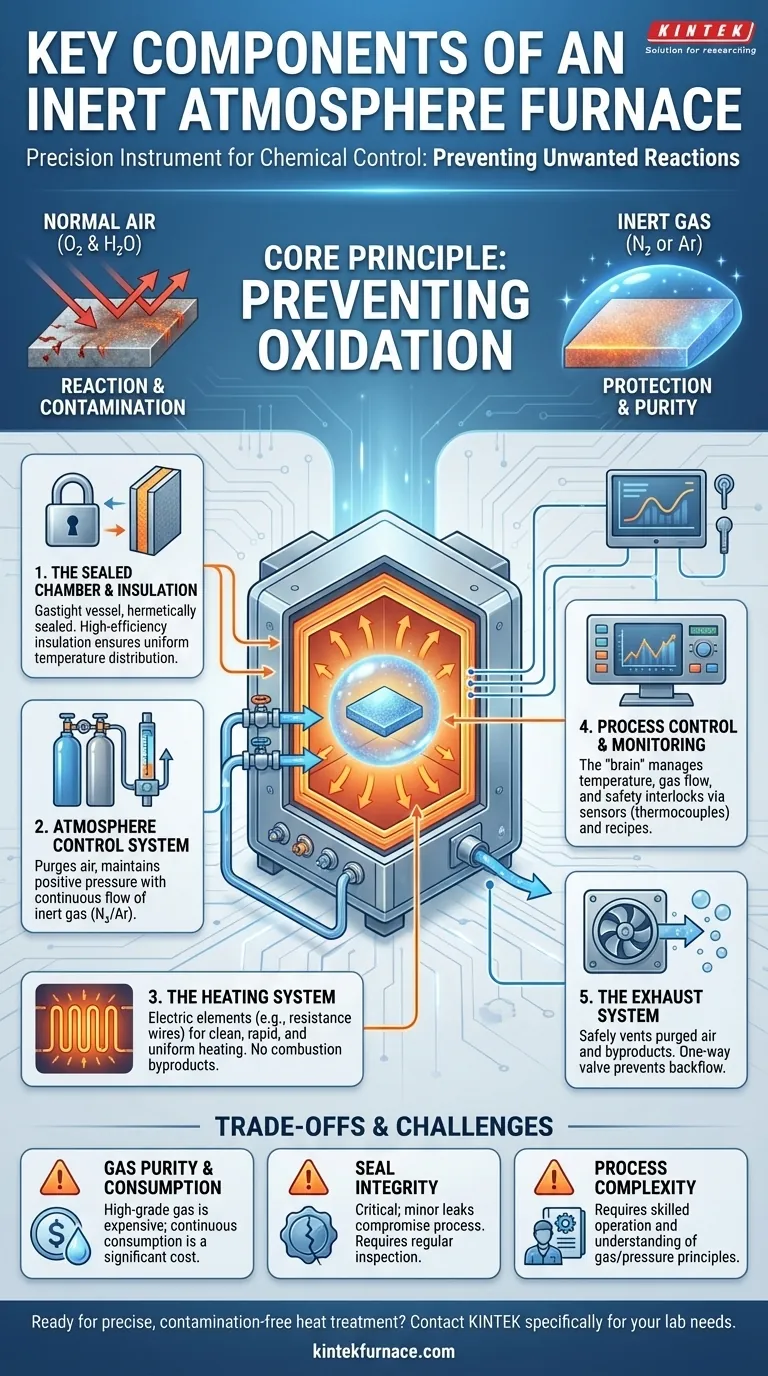

At its core, an inert atmosphere furnace is a system built around five fundamental components. These are a perfectly sealed heating chamber, a gas supply and control system to introduce inert gases, an electric heating system to achieve target temperatures, a process control system to manage all variables, and an exhaust system to safely vent gases. Together, these parts create a highly controlled environment, free from reactive gases like oxygen.

An inert atmosphere furnace isn't simply a device for heating; it's a precision instrument for chemical control. Its primary function is to isolate a material from the ambient air, allowing high-temperature processes to occur without undesirable reactions like oxidation.

The Core Principle: Preventing Unwanted Reactions

The entire purpose of an inert atmosphere furnace is to perform heat treatment in a chemically inactive, or inert, environment. Processes like bright annealing, sintering, or brazing require high temperatures, which dramatically accelerate chemical reactions.

When performed in normal air, the oxygen and moisture present will rapidly react with the material's surface, causing oxidation, scaling, and contamination. This degrades the material's properties, finish, and structural integrity.

By replacing the air with a non-reactive gas—most commonly nitrogen or argon—the furnace ensures the material interacts only with heat, preserving its purity and achieving the desired metallurgical outcome.

Deconstructing the System: The Five Key Components

Each component of the furnace plays a critical, non-negotiable role in creating and maintaining this pristine environment. A failure in any one part compromises the entire process.

1. The Sealed Chamber and Insulation

The foundation of the furnace is the heating chamber, which must be hermetically sealed. This chamber is a gastight vessel designed to withstand high temperatures and prevent any outside air from leaking in.

High-efficiency insulation materials surround the chamber. Their job is not just to retain heat for energy efficiency but also to ensure uniform temperature distribution, which is critical for consistent results across the entire workpiece.

2. The Atmosphere Control System

This system is the heart of the furnace. It consists of a gas supply, typically from high-purity liquid or compressed gas cylinders, connected through a series of valves and flow meters.

This system purges the initial air from the chamber before the heating cycle begins. It then maintains a slight positive pressure with a continuous, low-volume flow of inert gas throughout the process, ensuring any potential micro-leaks flow outward, not inward.

3. The Heating System

The heat itself is almost always generated by electric heating elements, such as resistance wires or silicon carbide plates. These are preferred over direct gas firing because they do not introduce combustion byproducts into the controlled atmosphere.

The placement and power of these elements are engineered to provide rapid, uniform heating and precise temperature control within the chamber.

4. The Process Control and Monitoring System

The "brain" of the operation is the process control system. This integrated unit uses thermocouples to precisely monitor the internal temperature and adjusts power to the heating elements accordingly.

Simultaneously, it manages the atmosphere control system, regulating gas flow rates based on pre-programmed recipes. Modern systems include safety interlocks and alarms—a protection system—that monitor for abnormal conditions like over-temperature or loss of gas pressure.

5. The Exhaust System

The exhaust, or outlet, system is just as important as the inlet. It allows the purged air and any byproducts from the heating process to be safely vented from the chamber.

A simple bubbler or a one-way valve is often used to provide a visual confirmation of positive pressure and prevent backflow of ambient air into the furnace.

Understanding the Trade-offs and Limitations

While powerful, these furnaces are not without their operational challenges. Understanding them is key to successful operation.

Gas Purity and Consumption

The final product quality is directly tied to the purity of the inert gas used. Achieving ultra-pure environments requires expensive, high-grade gases and increases operational costs. Gas consumption is a significant and continuous expense.

Seal Integrity is Non-Negotiable

The entire process hinges on the quality of the chamber's seals. Gaskets and door seals degrade over time with thermal cycling. Even a minor leak can introduce enough oxygen to ruin a sensitive process, making regular inspection and maintenance critical.

Process Complexity

Operating an inert atmosphere furnace requires more skill than a standard oven. The operator must understand the principles of gas purging, pressure regulation, and the specific requirements of the material being processed to avoid costly errors.

Making the Right Choice for Your Process

Selecting and operating a furnace requires matching its capabilities to your specific technical goal.

- If your primary focus is high-purity processing (e.g., sintering reactive metals): Prioritize a furnace with superior seal integrity, advanced atmosphere controls, and compatibility with high-purity gas sources.

- If your primary focus is general-purpose bright annealing: A standard furnace with reliable temperature uniformity and consistent inert gas flow will be effective.

- If your primary focus is process repeatability and automation: Invest in a system with a programmable logic controller (PLC) that can precisely manage and log all process variables.

Ultimately, mastering an inert atmosphere furnace is about mastering control over the processing environment.

Summary Table:

| Component | Key Function |

|---|---|

| Sealed Chamber and Insulation | Provides a gastight, high-temperature environment for uniform heating |

| Atmosphere Control System | Manages inert gas flow to maintain a non-reactive atmosphere |

| Heating System | Uses electric elements for precise, uniform temperature control |

| Process Control and Monitoring | Regulates temperature and gas flow with safety features |

| Exhaust System | Safely vents gases and prevents backflow of ambient air |

Ready to achieve precise, contamination-free heat treatment in your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions, including inert atmosphere furnaces. Leveraging our exceptional R&D and in-house manufacturing, we offer a product line with Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can support your laboratory needs!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process