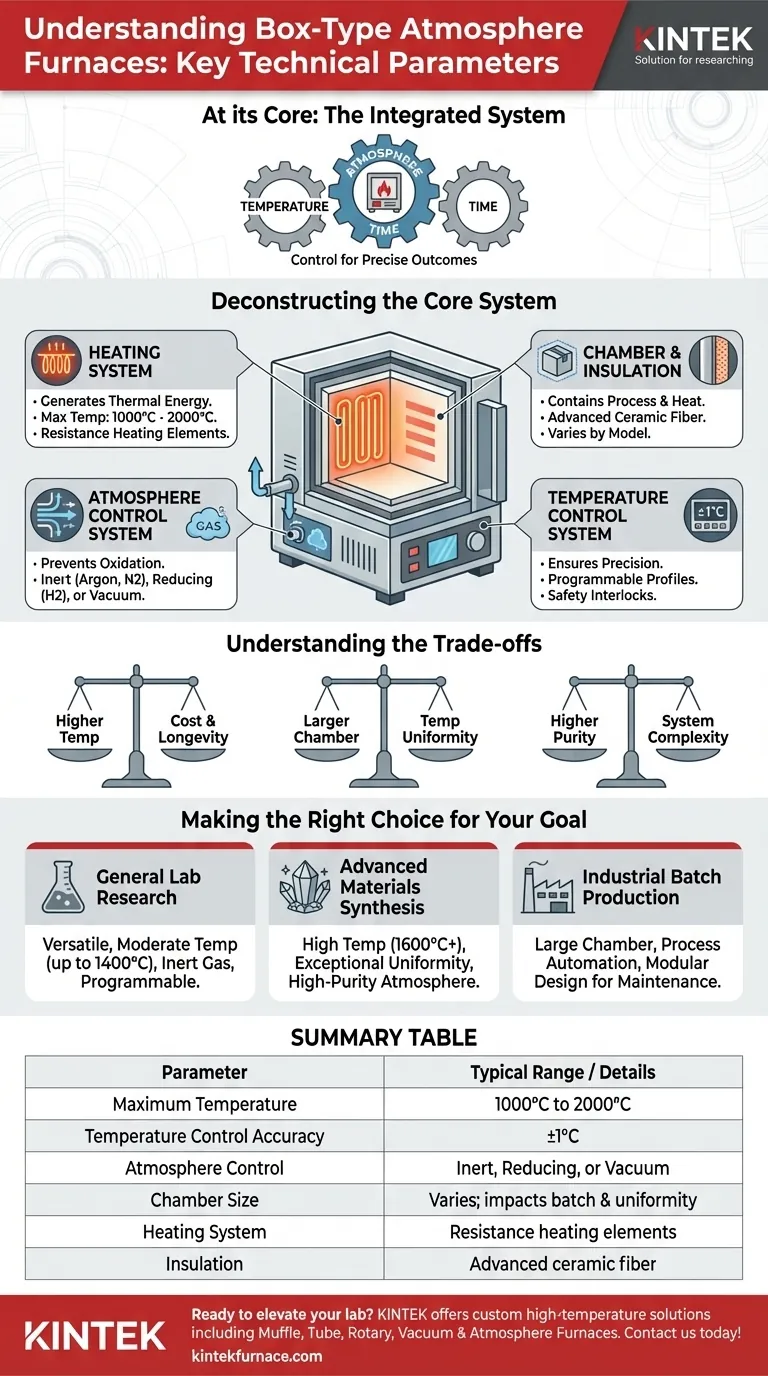

At its core, a box-type atmosphere furnace is defined by its ability to control three critical variables: temperature, atmosphere, and time. The general technical parameters that quantify this control include a maximum temperature range (typically 1000°C to 2000°C), temperature control accuracy (often within ±1°C), the type of atmosphere control system (e.g., inert or reducing gas), and the physical chamber size.

Understanding the specifications of a box-type atmosphere furnace is not about memorizing numbers. It's about seeing the furnace as an integrated system where each parameter—from heating element to insulation—directly impacts your ability to achieve a precise, repeatable outcome for your materials.

Deconstructing the Core System

A box-type atmosphere furnace is a purpose-built environment. Its design centers on creating and maintaining highly specific conditions that would be impossible in open air. To understand its parameters, you must first understand its constituent parts.

The Heating System: Generating Thermal Energy

The furnace's primary function is to generate heat. This is governed by its maximum temperature and the elements that produce it.

Most models use resistance heating, where an electric current is passed through specialized heating elements (like resistance wire) to generate thermal energy. The maximum achievable temperature, from 1000°C for basic processes to over 2000°C for advanced ceramics, is a primary specification determined by the material of these elements.

The Chamber and Insulation: Containing the Process

The furnace chamber is the sealed box where the work happens. Its internal dimensions dictate the maximum size and volume of the material you can process in a single batch.

Surrounding the chamber are high-performance insulation materials, typically advanced ceramic fiber. This insulation is critical for minimizing heat loss, ensuring energy efficiency, and maintaining a stable and uniform temperature inside the chamber.

The Atmosphere Control System: The Defining Feature

This system is what separates an atmosphere furnace from a standard furnace. Its purpose is to displace the ambient air (which contains ~21% oxygen) with a specific gas to prevent oxidation and other unwanted chemical reactions at high temperatures.

Options typically include:

- Inert Atmosphere: Using gases like Argon or Nitrogen to create a non-reactive environment.

- Reducing Atmosphere: Using gases like Hydrogen to actively remove oxygen from the material's surface.

- Vacuum Conditions: Pumping air out to create a near-vacuum, though this is a feature of more specialized models.

The effectiveness of this system is determined by the quality of the chamber seals and the precision of the gas supply system.

The Temperature Control System: Ensuring Precision

Arguably the most critical system for repeatability, the temperature controller manages the heating elements. Modern furnaces feature advanced, programmable controllers that ensure precise thermal regulation, often with an accuracy of ±1°C.

This allows users to execute complex heating profiles with multiple stages, ramps, and soaks, ensuring that every process is consistent and repeatable. Safety interlocks are also integrated here to ensure operational reliability.

Understanding the Trade-offs

Selecting a furnace involves balancing performance with cost and complexity. The ideal specifications are always tied to the intended application.

Temperature Range vs. Cost and Longevity

Achieving higher temperatures requires more exotic and expensive heating elements and insulation materials. These high-performance components often have a shorter operational lifespan and are more costly to replace, creating a direct trade-off between maximum temperature capability and long-term operating cost.

Chamber Size vs. Temperature Uniformity

In a larger chamber, it becomes more difficult to maintain a perfectly uniform temperature throughout the entire volume. Hot and cold spots can develop, affecting the consistency of your results. Advanced furnaces combat this with multiple heating zones and sophisticated controllers, but this adds significant cost and complexity to the system.

Atmosphere Purity vs. System Design

Maintaining a high-purity inert atmosphere requires exceptional chamber sealing and a more complex gas management system. Minor leaks can introduce contaminants like oxygen and moisture, compromising sensitive processes. A simple, low-cost furnace may be suitable for bulk heat treating, but it will not suffice for applications requiring near-perfect atmospheric conditions.

Making the Right Choice for Your Goal

The "best" furnace is the one whose technical parameters align perfectly with your process requirements. To make an informed decision, evaluate the specifications based on your primary objective.

- If your primary focus is general lab research: A versatile furnace with a moderate temperature range (up to 1200°C-1400°C), reliable atmosphere control for inert gas, and a precise programmable controller is often the most practical choice.

- If your primary focus is advanced materials synthesis: Prioritize a high maximum temperature (1600°C+), exceptional temperature uniformity, and a robust, high-purity atmosphere system.

- If your primary focus is industrial batch production: Focus on a large chamber size, process automation, a user-friendly interface, and a modular design that simplifies maintenance to minimize downtime.

By understanding how each parameter directly influences the internal environment, you can select a furnace that acts as a precise tool for your specific scientific or industrial goal.

Summary Table:

| Parameter | Typical Range / Details |

|---|---|

| Maximum Temperature | 1000°C to 2000°C |

| Temperature Control Accuracy | ±1°C |

| Atmosphere Control | Inert (e.g., Argon, Nitrogen), Reducing (e.g., Hydrogen), or Vacuum |

| Chamber Size | Varies by model; impacts batch capacity and temperature uniformity |

| Heating System | Resistance heating with elements like resistance wire |

| Insulation | Advanced ceramic fiber for energy efficiency and stability |

Ready to elevate your lab's capabilities with a custom box-type atmosphere furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your furnace precisely meets unique experimental needs, from general research to advanced materials synthesis and industrial production. Contact us today to discuss how we can optimize your processes with reliable, high-performance equipment!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a furnace atmosphere protect materials from surface reactions? Master Controlled Heat Treatment

- What are some industrial applications of low vacuum atmosphere furnaces? Boost Efficiency in Heat Treatment Processes

- Why are vacuum or atmosphere control systems required for Fe, Co, and Ni single-atom catalysts? Ensure Atomic Precision

- What is the purpose of switching between N2 and H2 in electrical steel annealing? Master Atmosphere Control

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What materials are used in the construction of a retort furnace? Discover Key Components for High-Temp Control

- What are the advantages of a controlled atmosphere furnace over tube furnaces? Superior Process Control for Sensitive Materials

- How are inert atmosphere furnaces sealed and prepared for operation? Ensure Process Integrity and Prevent Oxidation