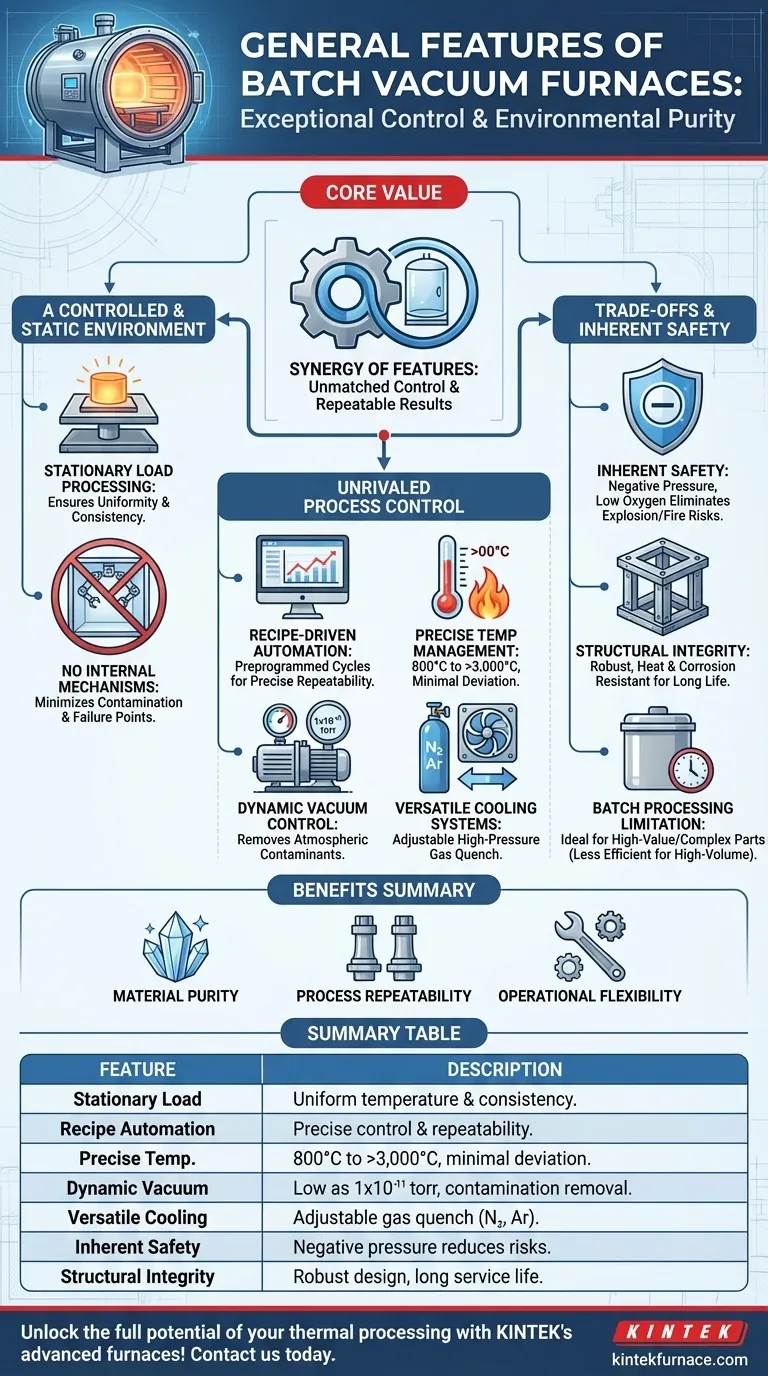

At their core, batch vacuum furnaces are defined by exceptional process control and environmental purity. They achieve this through several key features: a stationary workload, recipe-based automation for precise control of temperature and vacuum levels, versatile gas cooling systems, and a design that minimizes contamination.

The defining characteristic of a batch vacuum furnace is not any single component, but the synergy of its features. This combination provides an unmatched level of control over the entire thermal processing cycle, which is the fundamental reason they are essential for producing high-quality, repeatable results.

The Foundation: A Controlled and Static Environment

The physical design of a batch furnace is deliberately simple to maximize control and reliability. It centers on treating one distinct load at a time in a sealed, stationary chamber.

Stationary Load Processing

A core feature is that the workload remains stationary throughout the entire heating and cooling cycle. The parts are loaded into the furnace, the cycle runs, and they are not moved again until they are unloaded.

This static approach is fundamental to ensuring temperature uniformity and process consistency across the entire load.

Eliminating Internal Mechanisms

By design, these furnaces have no load transfer mechanisms operating within the hot zone. This simplicity reduces the number of potential failure points and, crucially, eliminates a major source of contamination (e.g., lubricants, wear particles) inside the processing chamber.

Unrivaled Process Control and Flexibility

The primary value of a batch vacuum furnace comes from its ability to be programmed and controlled with incredible precision. This allows for highly customized and repeatable thermal processes.

Recipe-Driven Automation

Each load can be run with a unique, preprogrammed recipe. This computer-controlled process dictates every variable—from heating rates to vacuum levels and cooling parameters—ensuring that the exact same process is executed every time for a given part.

Precise Temperature Management

Temperature control is exceptionally precise, often managed by thermocouples placed on the furnace or the load itself. These systems can achieve uniform temperatures ranging from 800°C to over 3,000°C (1,500–5,400°F) with minimal deviation.

This allows for multi-stage heating, soaking, and cooling profiles tailored to the specific metallurgical requirements of the material being processed.

Dynamic Vacuum and Atmosphere Control

The furnace can achieve and maintain specific vacuum levels, sometimes as low as 1x10⁻¹¹ torr. This vacuum environment can be programmed to change at different stages of the cycle.

This control removes atmospheric contaminants and allows for the removal of by-products (degassing) from the material itself as it is heated.

Versatile Cooling Systems

After the heating cycle, parts are typically cooled rapidly using a high-pressure gas quench. The type of gas (e.g., Nitrogen, Argon) and its pressure can be varied based on the recipe. This allows for precise control over cooling rates, which is critical for achieving desired material hardness and microstructure.

Understanding the Trade-offs and Inherent Safety

While incredibly powerful, it's important to understand the design's inherent advantages and operational context.

Inherent Safety by Design

Vacuum furnaces operate at negative pressure, which inherently eliminates the risk of explosion that can be associated with positive-pressure vessels.

Furthermore, the extremely low oxygen content within the chamber minimizes the risk of fire or unwanted oxidation of the workpiece, making them significantly safer than many conventional atmosphere furnaces.

Structural Integrity and Longevity

These furnaces are built for demanding industrial environments. They typically feature robust construction with excellent heat and corrosion resistance, leading to a long service life and stable, reliable performance.

The Batch Processing Limitation

The most significant trade-off is implied in the name: "batch" processing. Unlike continuous furnaces where parts move through different zones, a batch furnace completes an entire cycle on one load before the next can begin. This makes it ideal for high-value or complex parts but potentially less efficient for very high-volume, uniform production.

How This Applies to Your Application

The features of a batch vacuum furnace directly translate to specific manufacturing goals.

- If your primary focus is ultimate material purity and quality: The precise control over vacuum levels is your key advantage, allowing for degassing and the prevention of contamination.

- If your primary focus is process repeatability for critical components: The recipe-driven, computer-controlled automation ensures every part receives the exact same thermal treatment, cycle after cycle.

- If your primary focus is operational flexibility for diverse parts: The ability to program unique recipes for different part geometries, materials, and required outcomes makes the furnace a highly versatile asset.

Ultimately, these features combine to make the batch vacuum furnace an indispensable and highly reliable tool for achieving the highest standards in modern materials manufacturing.

Summary Table:

| Feature | Description |

|---|---|

| Stationary Load Processing | Workload remains static for uniform temperature and consistency. |

| Recipe-Driven Automation | Preprogrammed cycles ensure precise control and repeatability. |

| Precise Temperature Management | Thermocouple-controlled heating from 800°C to 3,000°C with minimal deviation. |

| Dynamic Vacuum Control | Achieves vacuum levels as low as 1x10⁻¹¹ torr for contamination removal. |

| Versatile Cooling Systems | Adjustable gas quench (e.g., Nitrogen, Argon) for controlled cooling rates. |

| Inherent Safety | Negative pressure operation reduces explosion and fire risks. |

| Structural Integrity | Robust design with heat and corrosion resistance for long service life. |

| Batch Processing Limitation | Ideal for high-value parts but less efficient for high-volume production. |

Unlock the full potential of your thermal processing with KINTEK's advanced batch vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior process control, repeatability, and safety. Contact us today to discuss how our furnaces can enhance your material quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability