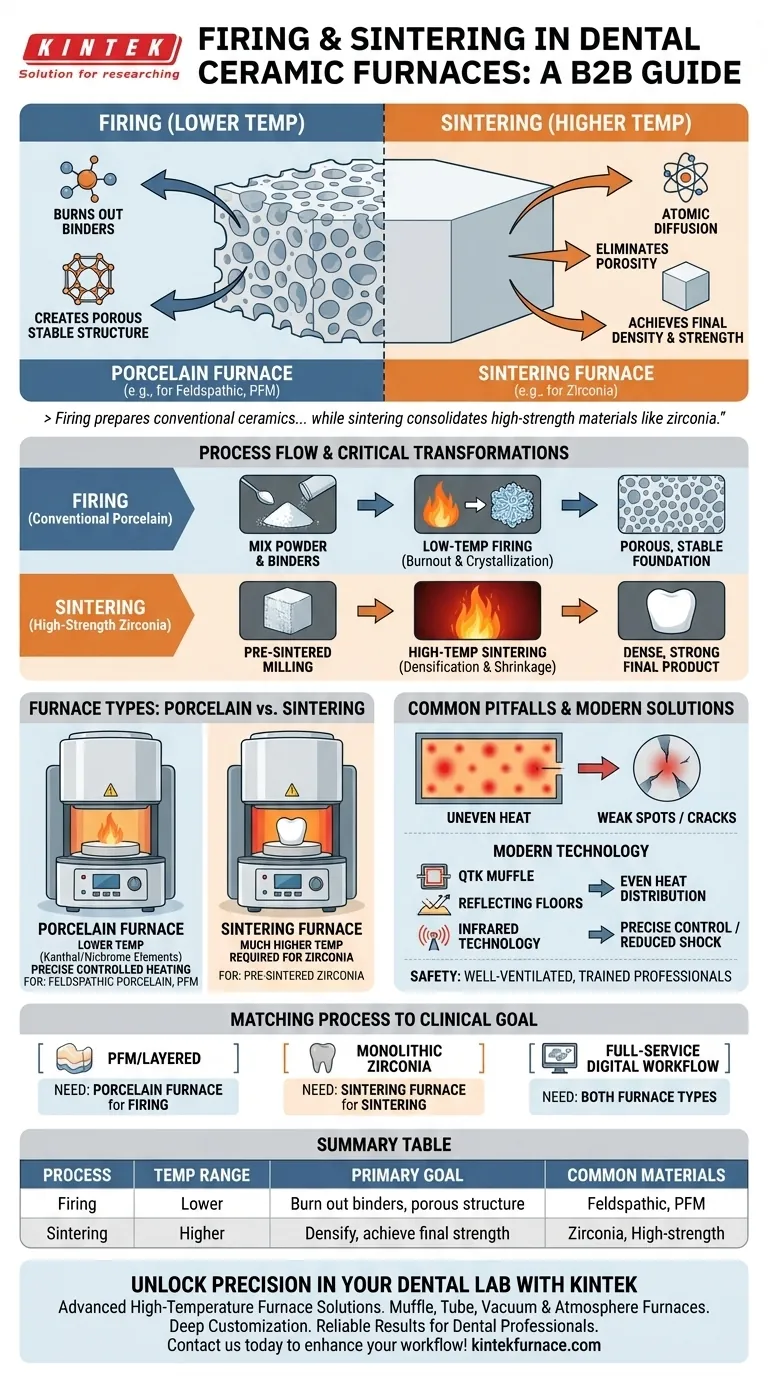

In dental ceramics, firing and sintering are the two essential thermal processes that convert a fragile, milled, or layered restoration into its final, high-strength state. Firing is a lower-temperature preparatory step that cleans and stabilizes the ceramic. Sintering is the subsequent high-temperature process that fully densifies and solidifies the material, giving it the required strength and aesthetic properties.

While often used interchangeably in conversation, firing and sintering are fundamentally different processes. Firing prepares conventional ceramics at a lower temperature, while sintering consolidates high-strength materials like zirconia at a much higher temperature. Understanding this distinction is critical for achieving optimal restoration quality.

The Foundational Role of Firing

The firing process, often performed in a "porcelain furnace," is the first stage of heat treatment for many dental ceramics. Its primary goal is not final strength but preparation.

Preparing the Ceramic Foundation

During fabrication, ceramic powders are mixed with organic binders and liquids. The initial, low-temperature firing cycle is designed specifically to burn out these organic materials cleanly, preventing discoloration or structural defects in the final restoration.

Creating a Stable, Porous Structure

After the binders are removed, the ceramic particles begin to fuse at their contact points. This creates a porous but stable structure that has enough integrity to be handled and is prepared for the next, more intense heat treatment phase.

Materials and Applications

Firing is the key process for crystallizing and glazing conventional dental porcelain, such as that used for porcelain-fused-to-metal (PFM) crowns or for layering over stronger core materials.

The Critical Transformation of Sintering

Sintering is a more aggressive thermal process that drives the ceramic to its final, dense state. This is where the restoration gains its ultimate durability.

From Porous to Solid

Sintering occurs at a temperature high enough to cause significant atomic diffusion. The ceramic particles bond together powerfully, eliminating the microscopic pores left over from the firing stage and causing the restoration to shrink to its final size.

Achieving Final Density and Strength

This elimination of porosity is what dramatically increases the material's density. This densification is directly responsible for the final flexural strength, fracture toughness, and longevity of the restoration, particularly for high-performance materials.

The Zirconia Connection

Sintering is absolutely essential for materials like zirconia. After being milled in a soft, chalk-like pre-sintered state, the zirconia restoration undergoes a precise, high-temperature sintering cycle. This transforms it into the incredibly strong, biocompatible final product used for monolithic crowns and bridges.

Understanding the Trade-offs: Porcelain vs. Sintering Furnaces

The difference between firing and sintering dictates the need for two distinct types of furnaces.

Temperature Range and Capability

Porcelain furnaces operate at lower temperatures, typically using Kanthal or Nichrome heating elements. They are designed for the precise, controlled heating ramps required for firing and glazing conventional ceramics.

Sintering furnaces must reach much higher temperatures to properly densify materials like zirconia. Attempting to sinter zirconia in a standard porcelain furnace will fail, as the furnace cannot reach the required temperature.

Material Compatibility

A porcelain furnace is the correct tool for processing feldspathic porcelain, leucite-reinforced ceramics, and other conventional materials.

A sintering furnace is non-negotiable for processing pre-sintered zirconia. It is a specialized piece of equipment designed for this single, high-temperature purpose.

Common Pitfalls and How to Avoid Them

Achieving consistent, high-quality results depends on mitigating variables in the thermal process.

The Danger of Uneven Heat

Inconsistent temperature distribution within a furnace is a primary cause of failure. It leads to uneven sintering, creating internal stresses and weak spots that can result in a compromised fit or catastrophic cracks in the final restoration.

Modern Technology for Consistency

To ensure reliable outcomes, modern furnaces utilize advanced features. QTK muffle technology and reflecting floors promote even heat distribution, while infrared technology can monitor and control the process with greater precision, reducing thermal shock.

Safety and Operational Discipline

Both furnace types generate high heat and can release fumes from the materials being processed. They must be operated in well-ventilated areas by trained professionals who follow all manufacturer safety protocols to prevent hazards.

Matching the Process to Your Clinical Goal

Your material choice dictates the thermal processing required. Use this guide to determine your needs.

- If your primary focus is conventional porcelain-fused-to-metal (PFM) or layered restorations: A dedicated porcelain furnace for the firing process is your essential tool.

- If your primary focus is monolithic high-strength restorations: A high-temperature sintering furnace is non-negotiable for processing materials like zirconia.

- If your primary focus is a full-service digital workflow (e.g., CEREC/inLab): You will likely need both furnace types to cover the full range of ceramic and zirconia materials available.

Mastering the distinction between firing and sintering empowers you to select the right equipment and protocol for consistently superior clinical outcomes.

Summary Table:

| Process | Temperature Range | Primary Goal | Common Materials |

|---|---|---|---|

| Firing | Lower (e.g., for porcelain) | Burn out binders, create porous structure | Feldspathic porcelain, PFM ceramics |

| Sintering | Higher (e.g., for zirconia) | Densify material, achieve final strength | Zirconia, high-strength ceramics |

Unlock Precision in Your Dental Lab with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need a porcelain furnace for firing or a sintering furnace for zirconia, we deliver reliable, consistent results for dental professionals. Contact us today to discuss how our furnaces can enhance your workflow and restoration quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations