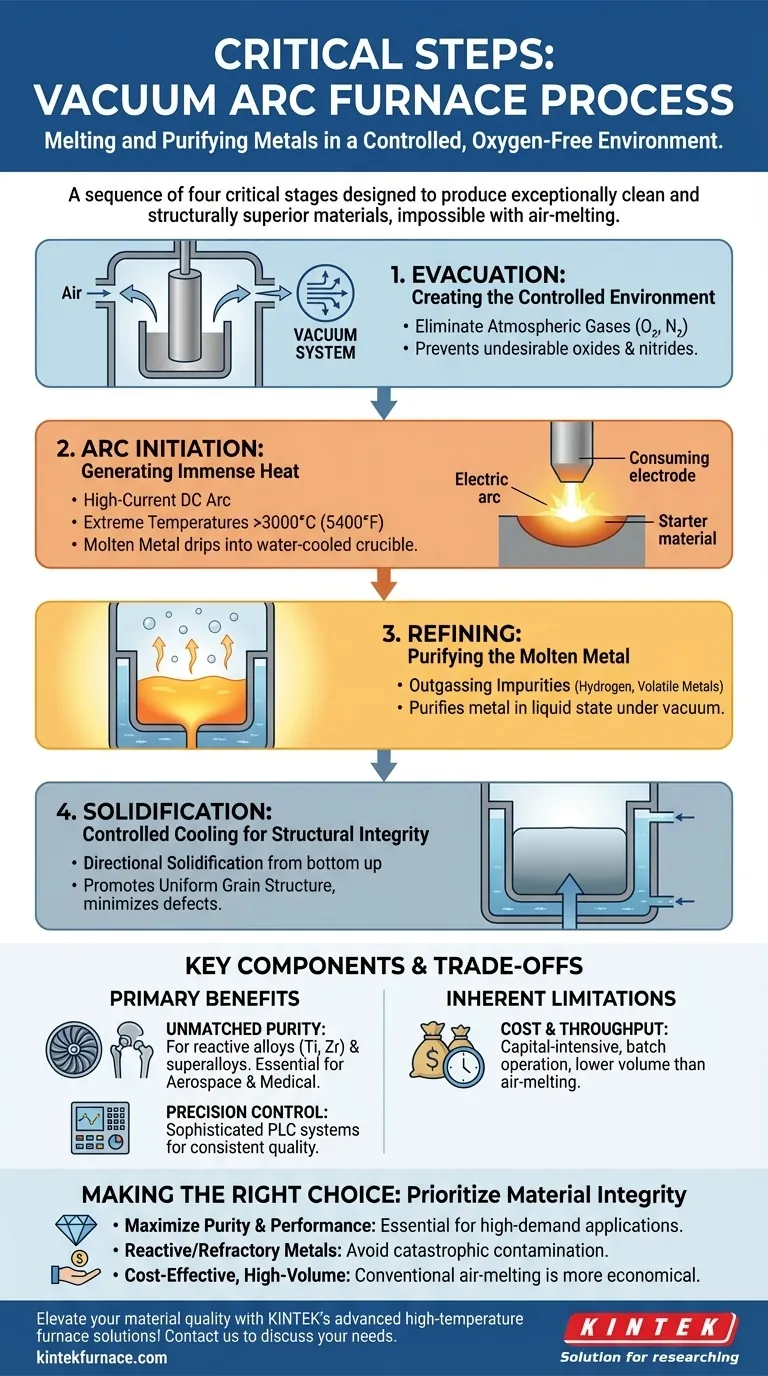

At its core, the vacuum arc furnace process is a sequence of four critical stages designed to melt and purify metals in a highly controlled, oxygen-free environment. It begins with creating a vacuum, then uses an electric arc to melt the material, followed by a refining phase to remove impurities, and concludes with controlled cooling to form a high-integrity solid ingot.

The fundamental purpose of the vacuum arc furnace is not just to melt metal, but to use the vacuum as an active tool for purification. By eliminating atmospheric contamination and actively drawing out dissolved gases, the process produces exceptionally clean and structurally superior materials that are impossible to create with conventional air-melting techniques.

The Four Core Stages of the Vacuum Arc Process

Each stage in the process serves a distinct and critical function, building upon the last to achieve the final material properties. This method is a cornerstone for producing high-performance alloys used in demanding industries like aerospace and medicine.

Step 1: Evacuation - Creating the Controlled Environment

The entire process begins by placing the raw material, typically in the form of a large cylindrical electrode, inside a sealed, water-cooled crucible and chamber. A powerful vacuum system, consisting of mechanical and diffusion pumps, then removes the air.

The goal is to create a near-perfect vacuum, eliminating atmospheric gases like oxygen and nitrogen. These gases would otherwise react with the molten metal, forming undesirable oxides and nitrides that compromise the material's strength and integrity.

Step 2: Arc Initiation - Generating Immense Heat

Once the vacuum is established, a high-current DC power supply is activated. This strikes a powerful electric arc between the tip of the raw material electrode (the cathode) and a small amount of starter material at the bottom of the crucible (the anode).

This arc generates extreme temperatures, typically exceeding 3000°C (5400°F), causing the tip of the electrode to melt progressively. The molten metal drips down into the water-cooled copper crucible below, forming a growing pool.

Step 3: Refining - Purifying the Molten Metal

This is where the true value of the vacuum becomes apparent. The combination of high temperature and low pressure causes dissolved impurities within the molten metal—especially gases like hydrogen and volatile metallic elements—to "boil" out.

These impurities are drawn away by the vacuum system, effectively purifying the metal in its liquid state. This outgassing process is critical for removing elements that cause embrittlement and reduce fatigue life in the final product.

Step 4: Solidification - Controlled Cooling for Structural Integrity

As the molten metal collects in the crucible, the water-cooled walls rapidly extract heat from the outside of the pool. The metal solidifies directionally, from the bottom up, as the electrode continues to melt and drip.

This highly controlled solidification process promotes a uniform grain structure and minimizes defects like porosity and segregation. The final result is a dense, homogeneous, and refined ingot with superior mechanical properties.

Understanding the Key Components and Trade-offs

The effectiveness of the vacuum arc process is a direct result of its specialized equipment. However, this sophistication comes with inherent limitations.

The Primary Benefit: Unmatched Purity

The defining advantage is the ability to produce metals with extremely low levels of dissolved gases and non-metallic inclusions. This is non-negotiable for reactive alloys like titanium and zirconium or high-performance superalloys used in jet engine turbine blades.

The Benefit of Precision Control

Modern vacuum arc furnaces are managed by sophisticated PLC (Programmable Logic Controller) systems. These allow for precise and repeatable control over melt rate, arc voltage, vacuum pressure, and cooling. This automation ensures consistent quality from batch to batch.

The Inherent Limitation: Cost and Throughput

This level of precision comes at a price. Vacuum arc furnaces are complex, capital-intensive systems that require significant energy and skilled operation. The process is also a batch operation, making its throughput lower than continuous, large-volume methods like air-melting.

Making the Right Choice for Your Goal

The decision to use the vacuum arc process should be driven entirely by the performance requirements of the final application.

- If your primary focus is maximum material purity and performance: The vacuum arc process is essential for creating superalloys, titanium alloys, and specialty steels for aerospace, medical implant, or defense applications.

- If your primary focus is reactive or refractory metals: This process is one of the only ways to melt materials like titanium, zirconium, and niobium without introducing catastrophic oxygen contamination.

- If your primary focus is cost-effective, high-volume production: For standard-grade metals where minor impurities are acceptable (e.g., structural steel), conventional air-melting is a far more economical choice.

Ultimately, specifying the vacuum arc process is a strategic decision to prioritize material integrity above all other manufacturing concerns.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| Evacuation | Remove air from chamber | Eliminate atmospheric gases to prevent contamination |

| Arc Initiation | Strike electric arc | Melt metal electrode with extreme heat |

| Refining | Outgas impurities under vacuum | Purify molten metal by removing dissolved gases |

| Solidification | Cool metal directionally | Form dense, uniform ingot with superior structure |

Elevate your material quality with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum arc furnaces and other systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity and performance in metals. Contact us today to discuss how we can support your goals in aerospace, medical, or other high-demand industries!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors