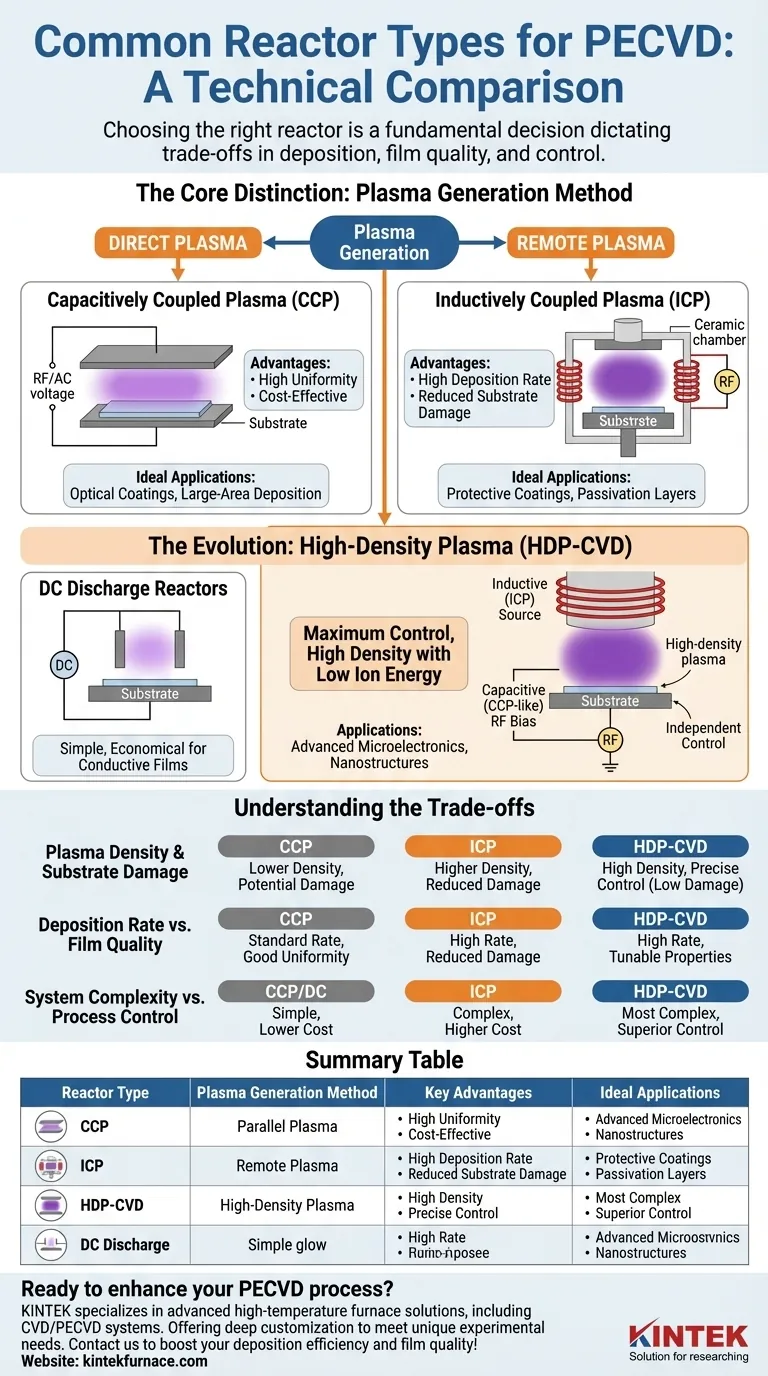

The most common reactor types for Plasma-Enhanced Chemical Vapor Deposition (PECVD) are capacitively coupled plasma (CCP) reactors, often called parallel plate reactors, and inductively coupled plasma (ICP) reactors. Simpler DC discharge systems are also used for specific applications, while advanced High-Density Plasma (HDP-CVD) systems combine inductive and capacitive methods for maximum control.

The choice of a PECVD reactor is not merely a hardware preference; it is a fundamental decision that dictates the trade-off between deposition rate, film quality, potential substrate damage, and overall process control.

The Core Distinction: Plasma Generation Method

The primary difference between major PECVD reactor types lies in how they generate and apply plasma energy. This distinction directly impacts the deposition process and the properties of the resulting thin film.

Capacitively Coupled Plasma (CCP) Reactors

A CCP reactor is the most common and classic PECVD design, often referred to as a direct PECVD or parallel plate system.

In this setup, the substrate sits on one of two parallel electrodes. An RF (Radio Frequency) or AC electrical field is applied across the electrodes, igniting and sustaining a plasma directly in the space between them, in contact with the substrate.

This design is valued for its relative simplicity and its ability to produce highly uniform films over very large areas.

Inductively Coupled Plasma (ICP) Reactors

An ICP reactor is a form of remote PECVD. Plasma is generated separately from the substrate.

Here, RF power is applied to a set of coils, typically wrapped around a ceramic chamber located above the substrate. This creates a strong, oscillating magnetic field which, in turn, induces an electric field that ignites an exceptionally dense plasma.

Because the plasma is generated "remotely," there is less direct interaction between the high-energy plasma generation zone and the sensitive substrate, which can reduce potential damage.

DC Discharge Reactors

The simplest configuration uses a DC (Direct Current) voltage to create a glow discharge.

This method is straightforward but is generally limited to the deposition of conductive materials. The continuous nature of the DC field makes it less effective for depositing insulating films, where charge can build up and disrupt the process.

The Evolution: High-Density Plasma (HDP-CVD)

Modern microelectronics often require capabilities beyond what standard CCP or ICP reactors can offer alone. This led to the development of High-Density Plasma Chemical Vapor Deposition (HDP-CVD) systems.

Combining the Best of Both Worlds

HDP-CVD is a hybrid approach. It typically uses an inductive (ICP) source to generate a very high-density plasma, enabling fast deposition rates.

Simultaneously, it uses a separate capacitive (CCP-like) RF bias applied directly to the substrate holder. This allows for independent control over the energy of ions bombarding the film as it grows. This dual control is the key advantage of HDP-CVD.

Understanding the Trade-offs

Choosing a reactor requires balancing competing factors. Your application's specific needs will determine which trade-offs are acceptable.

Plasma Density vs. Substrate Damage

CCP reactors generate a lower-density plasma compared to ICP. However, since the substrate is part of the plasma generation circuit, it can be subjected to higher-energy ion bombardment, which can cause damage.

ICP reactors produce a much higher-density plasma, but because the generation is remote, ion energy at the substrate can be lower, reducing damage. HDP-CVD offers the ultimate solution by decoupling plasma density from ion energy, providing high density with precisely controlled (and often low) ion energy.

Deposition Rate vs. Film Quality

Higher plasma density, as found in ICP and HDP systems, generally leads to higher deposition rates. This is crucial for manufacturing throughput.

However, simply depositing material quickly is not enough. HDP-CVD's ability to independently control ion energy allows for tuning of film properties like stress, density, and chemical composition (stoichiometry) during high-rate deposition.

System Complexity vs. Process Control

DC and CCP reactors are mechanically simpler and less expensive to build and operate.

ICP and especially HDP-CVD systems are significantly more complex and costly. This added expense is justified by the superior process control they offer, which is non-negotiable for fabricating advanced semiconductor devices.

Selecting the Right Reactor for Your Application

Your choice should be driven by the primary goal of your deposition process.

- If your primary focus is large-area uniformity and cost-effectiveness (e.g., optical coatings): A standard Capacitively Coupled Plasma (CCP) reactor is often the most practical choice.

- If your primary focus is a high deposition rate with reduced substrate damage (e.g., protective coatings, passivation layers): An Inductively Coupled Plasma (ICP) reactor provides the necessary high-density plasma.

- If your primary focus is maximum control and filling complex nanostructures (e.g., advanced microelectronics): A High-Density Plasma (HDP-CVD) system is essential for its independent control over plasma density and ion energy.

- If your primary focus is the simple deposition of a conductive film: A basic DC discharge reactor may be a sufficient and highly economical solution.

Ultimately, understanding the reactor architecture is the key to mastering the deposition process and achieving the desired thin film properties for your specific goal.

Summary Table:

| Reactor Type | Plasma Generation Method | Key Advantages | Ideal Applications |

|---|---|---|---|

| Capacitively Coupled Plasma (CCP) | Direct, parallel plate electrodes | High uniformity, cost-effective | Optical coatings, large-area deposition |

| Inductively Coupled Plasma (ICP) | Remote, inductive coils | High deposition rate, reduced substrate damage | Protective coatings, passivation layers |

| High-Density Plasma (HDP-CVD) | Hybrid inductive and capacitive | Maximum control, high density with low ion energy | Advanced microelectronics, nanostructures |

| DC Discharge | Direct current glow discharge | Simple, economical for conductive films | Deposition of conductive materials |

Ready to enhance your PECVD process with the right reactor? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—whether for CCP, ICP, or HDP-CVD applications. Contact us today to discuss how our tailored solutions can boost your deposition efficiency and film quality!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition