Muffle furnaces are fundamentally high-temperature ovens used across scientific and industrial fields. Their core applications include analytical testing like ashing, materials processing like heat treating metals, and manufacturing processes like firing ceramics. What unites these diverse tasks is the need for extremely high heat within a chemically pure and precisely controlled environment.

The critical function of a muffle furnace is not just to get hot, but to do so without contaminating the sample. By isolating the material inside a "muffle" chamber, it provides a clean, controlled environment, making it indispensable for processes where chemical purity and material integrity are paramount.

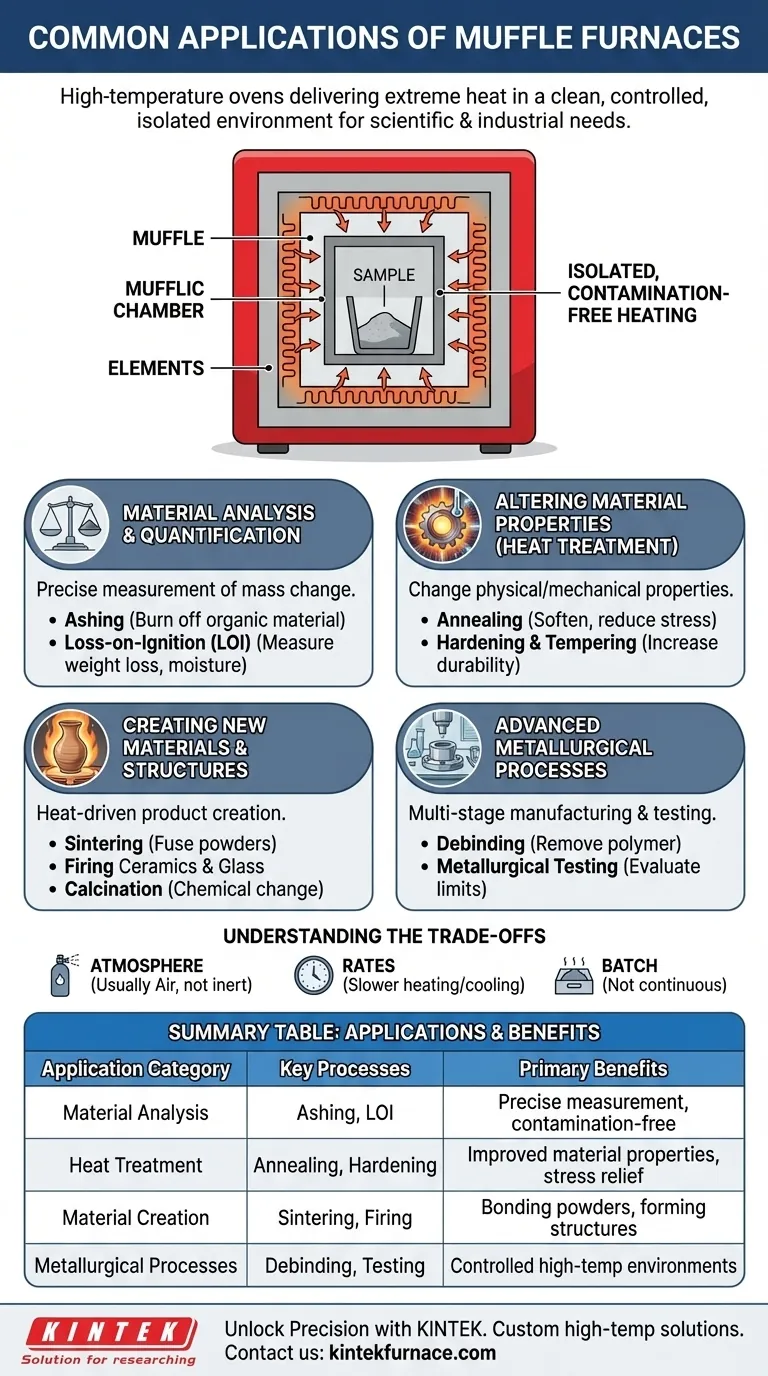

The Core Principle: Isolated, High-Temperature Heating

To understand the applications of a muffle furnace, you must first understand its design principle. The name itself reveals its function.

What "Muffle" Means

The term "muffle" refers to the furnace's inner chamber, which encloses the material being heated. This chamber separates the sample from the actual heating elements.

This design ensures that heat is transferred indirectly to the sample, typically through thermal conduction, convection, and radiation.

Eliminating Contamination

In modern electric muffle furnaces, this separation is critical. Because there is no combustion, no byproducts like soot or carbon monoxide are introduced into the chamber.

This guarantees a clean heating environment, which is essential for sensitive analytical work or for creating high-purity materials where any foreign substance could ruin the result.

Achieving Precise Temperature Control

Muffle furnaces provide exceptional temperature uniformity and control, with some models capable of reaching 1,800°C (3,272°F).

This precision allows users to execute complex heating profiles, such as slowly ramping up the temperature, holding it at a specific point for hours (a "soak"), and then cooling it down at a controlled rate.

Key Applications by Function

The combination of high heat, purity, and control makes the muffle furnace a versatile tool. Its applications can be grouped by their primary objective.

Material Analysis and Quantification

This category involves heating a sample to measure a change in its mass or composition. The furnace's clean environment ensures that the only changes measured are from the sample itself.

Key processes include:

- Ashing: Burning off all organic material to precisely measure the weight of the remaining inorganic, non-combustible residue (ash).

- Loss-on-Ignition (LOI): A broader technique used to determine the weight loss of a sample when heated to a high temperature, often to measure moisture or volatile organic content.

Altering Material Properties (Heat Treatment)

These processes use heat to change a material's physical and mechanical properties without melting it.

Key processes include:

- Annealing: Heating metal or glass and allowing it to cool slowly, which softens the material, removes internal stresses, and improves its ductility.

- Stress Relief: A lower-temperature process used to reduce internal stresses caused by manufacturing processes like welding or machining.

- Hardening & Tempering: A two-step process to increase the hardness and durability of steel.

Creating New Materials and Structures

Here, heat is the primary driver for creating a finished product from raw materials or inducing a fundamental chemical change.

Key processes include:

- Sintering: Fusing powdered materials (like ceramics or metals) together by heating them below their melting point until their particles bond.

- Firing Ceramics & Glass: Providing the high, consistent heat needed to harden clay into ceramic or to form and finish glass products.

- Calcination: A thermal treatment process that brings about a chemical change in a material, such as driving off carbon dioxide from limestone to create lime.

Advanced Metallurgical Processes

In sophisticated industrial applications, muffle furnaces are a critical component for multi-stage manufacturing.

Key processes include:

- Debinding: The process of removing polymer binder material from a part created via metal injection molding (MIM).

- Metallurgical Testing: Evaluating how metals and alloys behave under controlled high temperatures to determine their limits and properties.

Understanding the Trade-offs

While powerful, a muffle furnace is not the universal solution for all heating applications. Understanding its limitations is key to using it effectively.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. While this is clean (free of combustion byproducts), it is not inert. The oxygen in the air will react with many materials at high temperatures.

For processes requiring an inert (e.g., argon) or reactive (e.g., hydrogen) atmosphere, a more specialized and expensive controlled-atmosphere furnace is necessary.

Heating and Cooling Rates

Because heat must transfer indirectly through the muffle chamber walls, heating and cooling can be slower compared to direct-fired furnaces. This makes them ideal for processes that require stability and slow rates of change but less efficient for rapid thermal cycling.

Batch Processing

Muffle furnaces are inherently designed for batch processing—you load a sample, run a cycle, and unload it. They are generally not suited for the continuous, high-volume throughput seen in some large-scale industrial assembly lines.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on your primary goal.

- If your primary focus is analytical testing (e.g., ashing): Your priority is temperature accuracy and the absolute prevention of sample contamination from the heating source.

- If your primary focus is materials research: You need precise, programmable control over temperature profiles (ramps and soaks) and should consider if an inert atmosphere is needed.

- If your primary focus is industrial production (e.g., ceramics or heat treatment): You need durability, repeatable performance, and a chamber size that matches your batch requirements.

Understanding that the muffle furnace's core strength is its clean, isolated heat is the first step to applying it correctly to your work.

Summary Table:

| Application Category | Key Processes | Primary Benefits |

|---|---|---|

| Material Analysis | Ashing, Loss-on-Ignition | Precise measurement, contamination-free |

| Heat Treatment | Annealing, Hardening | Improved material properties, stress relief |

| Material Creation | Sintering, Firing Ceramics | Bonding powders, forming structures |

| Metallurgical Processes | Debinding, Testing | Controlled high-temperature environments |

Unlock Precision and Purity in Your High-Temperature Processes with KINTEK

Are you working in analytical testing, materials research, or industrial production and need reliable, contamination-free heating solutions? KINTEK specializes in advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental and production requirements—ensuring optimal performance for applications like ashing, sintering, and heat treatment.

Contact us today to discuss how our tailored furnace solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing