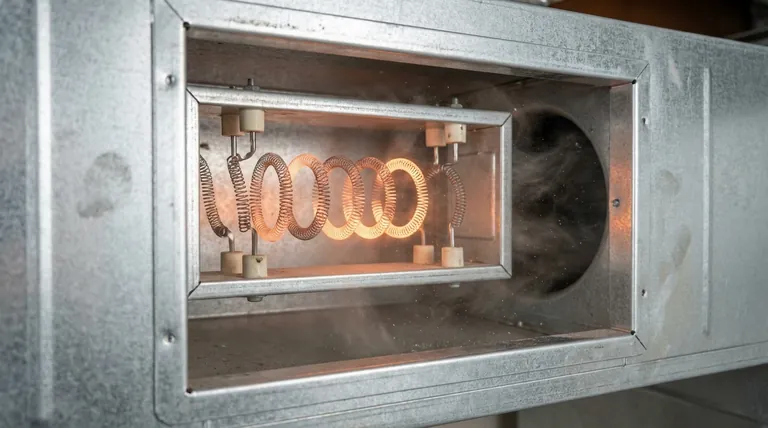

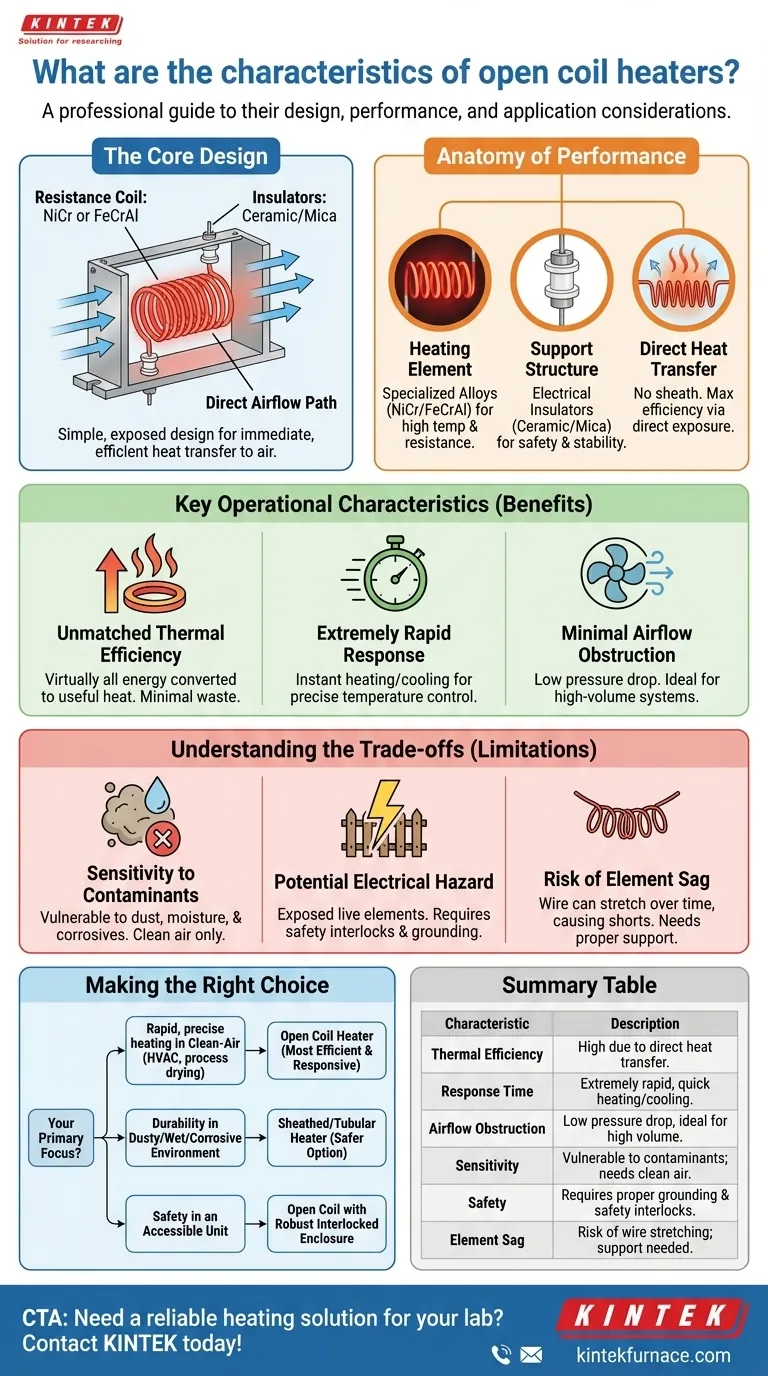

At their core, open coil heaters are defined by their simple yet highly effective design: an electrically resistant wire coil is suspended by insulators directly in the path of the airflow it is intended to heat. This construction, typically using nickel-chromium (NiCr) or iron-chromium-aluminum (FeCrAl) alloys for the coil and ceramic or mica for the insulators, allows for immediate and efficient energy transfer from the heating element to the air.

The primary advantage of an open coil heater is its exceptional thermal efficiency and rapid response time. However, this direct-exposure design means its performance and safety are critically dependent on a clean, non-hazardous operating environment.

The Anatomy of Performance

Understanding how an open coil heater is constructed reveals why it behaves the way it does. Its characteristics are a direct result of its minimalist and functional design.

The Heating Element: Resistance Coils

The heart of the heater is the coil itself. It is made from specialized alloys like NiCr or FeCrAl, chosen for their ability to resist high temperatures and oxidation while providing the electrical resistance needed to generate heat.

The specific alloy, wire gauge (diameter), and coil dimensions are carefully engineered to achieve the desired wattage output at a specific voltage.

The Support Structure: Insulators

The energized coil cannot touch any conductive surface. It is suspended within a frame using ceramic or mica insulators.

These materials are excellent electrical insulators and are capable of withstanding the high operating temperatures of the coil without degrading, ensuring both safety and structural integrity.

The Principle: Direct Heat Transfer

The defining characteristic of an open coil heater is the direct exposure of the heating element to the medium (usually air).

Unlike sheathed heaters where energy must first conduct through an outer tube and insulation, here the heat radiates directly from the coil's surface into the passing air, enabling maximum efficiency.

Key Operational Characteristics

The design of an open coil heater translates directly into a distinct set of performance benefits that make it the ideal choice for specific applications.

Unmatched Thermal Efficiency

Because there is no intermediate sheath or material to heat up first, virtually all the electrical energy is converted directly into useful heat within the airstream. This results in minimal wasted energy and lower operating costs.

Extremely Rapid Response

The low thermal mass of the thin wire coil allows it to reach operating temperature almost instantly when power is applied. It also cools down very quickly when power is cut, making these heaters ideal for applications requiring precise and rapid temperature control.

Minimal Airflow Obstruction

The "open" structure of the coil assembly presents a very low resistance to airflow. This low-pressure drop is a critical advantage in HVAC systems, duct heaters, and industrial dryers where maintaining high air volume and velocity is essential for performance.

Understanding the Trade-offs

The same design that provides such high efficiency also introduces specific limitations that must be respected. Ignoring these can lead to premature failure and safety hazards.

Sensitivity to Contaminants

The exposed coils are vulnerable. If the airstream contains dust, moisture, or corrosive vapors, these contaminants can accumulate on the hot element. This can create hot spots, cause the element to degrade, or lead to an electrical short.

For this reason, open coil heaters are only suitable for clean-air applications.

Potential Electrical Hazard

Since the heating elements are electrically live and exposed, safety is paramount. The entire heater assembly must be installed within a properly grounded enclosure with safety interlocks (e.g., on access panels) to prevent accidental human contact and the risk of electric shock.

Risk of Element Sag

Over hundreds of heating cycles, the resistance wire can slowly stretch or "sag" under its own weight, especially in horizontally mounted applications. Proper design includes sufficient support points to mitigate this, but if sag occurs, it can cause coils to touch, resulting in a short circuit and immediate failure.

Making the Right Choice for Your Application

Selecting the correct heating technology requires balancing efficiency, durability, and safety against the demands of your project.

- If your primary focus is rapid, precise heating in a clean-air system (like HVAC or process drying): An open coil heater is the most efficient and responsive choice available.

- If your primary focus is durability in a dusty, wet, or mildly corrosive environment: A sheathed or tubular heater is the safer option, as it protects the element from contamination.

- If your primary focus is safety in an easily accessible unit: You must ensure any open coil heater is installed within a robust, interlocked enclosure to eliminate any risk of accidental contact.

By understanding these fundamental characteristics and trade-offs, you can confidently determine if an open coil heater's efficiency meets the specific demands and constraints of your system.

Summary Table:

| Characteristic | Description |

|---|---|

| Thermal Efficiency | High due to direct heat transfer, minimizing energy waste. |

| Response Time | Extremely rapid, with quick heating and cooling for precise control. |

| Airflow Obstruction | Low pressure drop, ideal for high-volume air systems. |

| Sensitivity | Vulnerable to contaminants like dust and moisture; requires clean environments. |

| Safety | Needs proper grounding and safety interlocks to prevent electrical hazards. |

| Element Sag | Risk of wire stretching over time, potentially causing short circuits. |

Need a reliable heating solution for your lab? KINTEK specializes in advanced high-temperature furnaces, including custom designs to meet your unique needs. With our expertise in R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for clean-air applications, enhancing efficiency and safety. Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis