The primary benefits of a high-pressure metal tube reactor system lie in its ability to provide a robust, leak-free environment for reactions at elevated pressures (such as 1.0 MPa to 30 bar) while ensuring the precise control of process variables. By integrating with high-precision mass flow controllers and back-pressure valves, these systems maintain a stable Space Velocity (SV), which is physically required to accurately evaluate the catalyst's performance and scalability.

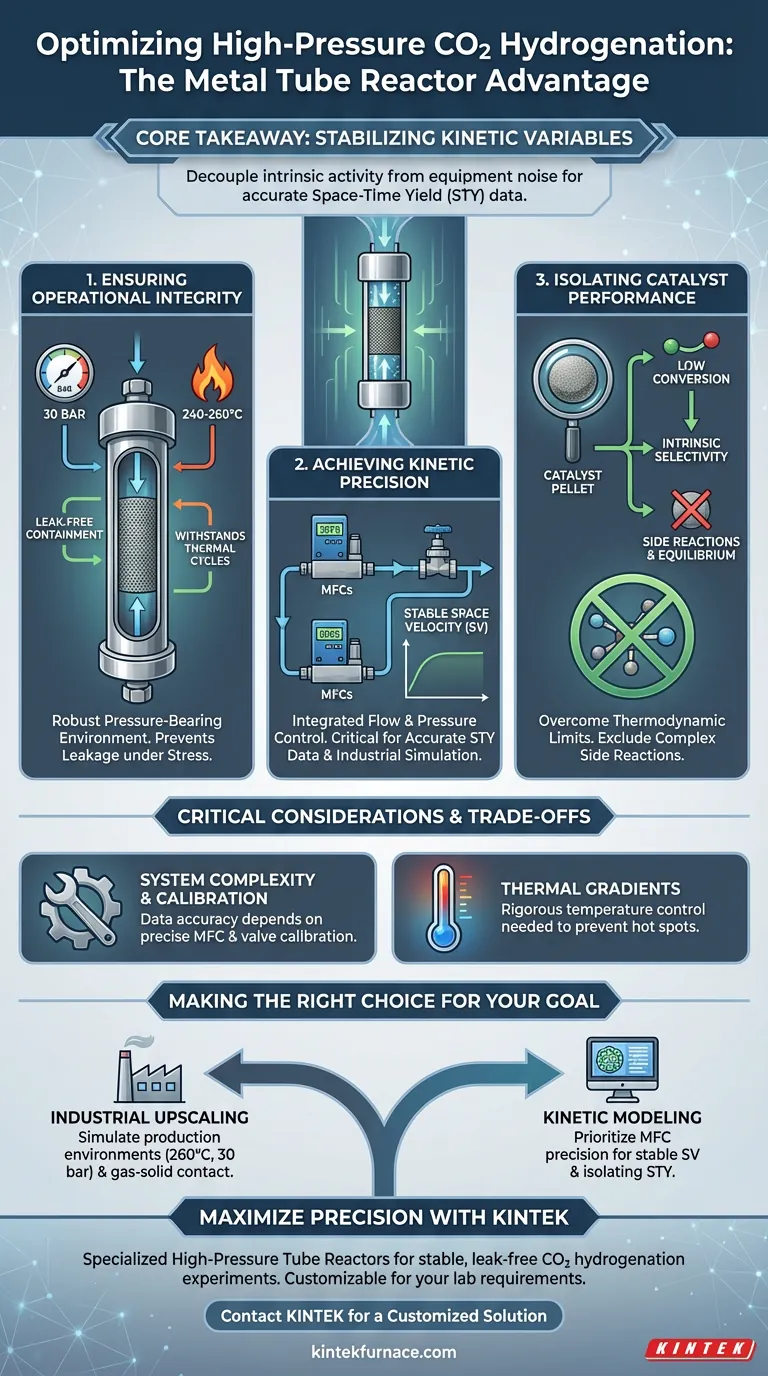

Core Takeaway The true value of this system is not just containment, but the stabilization of kinetic variables. It allows you to decouple the catalyst's intrinsic activity from environmental fluctuations, ensuring that measured Space-Time Yield (STY) data reflects the chemistry rather than equipment limitations.

Ensuring Operational Integrity

The Necessity of Robust Containment

High-pressure CO2 hydrogenation places immense stress on experimental equipment. A stainless steel fixed-bed reactor is designed specifically to withstand these conditions, providing a robust pressure-bearing environment.

Preventing Leakage Under Stress

Standard vessels may fail or leak when subjected to the thermal expansion and contraction associated with high-temperature and high-pressure cycles. A metal tube system ensures leak-free operation, which is critical for safety and mass balance accuracy when working with gases like H2 and CO2.

Achieving Kinetic Precision

Controlling Space Velocity (SV)

The physical structure of the reactor is only half the equation; its integration with peripherals is equally vital. When paired with high-precision mass flow controllers and back-pressure valves, the system ensures a constant flow rate relative to the catalyst volume.

The Link to Space-Time Yield (STY)

Maintaining a stable Space Velocity is the critical physical prerequisite for calculating Space-Time Yield. Without this stability, any data regarding the productivity of the catalyst per unit of time is unreliable.

Simulating Industrial Conditions

These systems allow researchers to mimic industrial production environments, such as operating at 240-260°C and pressures up to 30 bar. This ensures that the gas-solid contact and process stability observed in the lab are predictive of large-scale applications.

Isolating Catalyst Performance

Overcoming Thermodynamic Limits

In processes like methanol synthesis, reactions are often limited by thermodynamic equilibrium. A continuous flow high-pressure system allows you to operate at low conversion rates.

Excluding Side Reactions

By maintaining high space velocity control and precise pressure, you can measure product selectivity effectively. This setup allows you to exclude the influence of complex side reactions and equilibrium states, providing a clear view of the catalyst's intrinsic selectivity.

Understanding the Trade-offs

System Complexity and Calibration

While the metal tube provides the vessel, the accuracy of your data is entirely dependent on the calibration of the mass flow controllers and back-pressure valves. If these peripheral components drift, the robustness of the reactor itself cannot save the experiment.

Thermal Gradients

In fixed-bed tube reactors, heat transfer can sometimes be a challenge compared to other reactor types. You must ensure that the temperature control system is rigorous enough to prevent hot spots, which could skew the selectivity data you are trying to isolate.

Making the Right Choice for Your Goal

To maximize the utility of a high-pressure metal tube reactor, align your setup with your specific research objectives:

- If your primary focus is Industrial Upscaling: Ensure your system is rated for pressures up to 30 bar and temperatures of 260°C to accurately simulate production environments and gas-solid contact mechanics.

- If your primary focus is Kinetic Modeling: Prioritize the precision of your mass flow controllers to maintain stable Space Velocity, allowing you to isolate Space-Time Yield without the noise of equilibrium effects.

Ultimately, the high-pressure tube reactor transforms CO2 hydrogenation from a chaotic reaction into a measurable, controllable process.

Summary Table:

| Feature | Benefit for CO2 Hydrogenation |

|---|---|

| Stainless Steel Construction | Provides a robust, leak-free environment for pressures up to 30 bar. |

| Integrated Flow Control | Maintains stable Space Velocity (SV) for accurate kinetic data. |

| High-Precision MFCs | Ensures mass balance accuracy and repeatable gas-solid contact. |

| Back-Pressure Regulation | Enables operation at industrial scales (240-260°C) to simulate real-world conditions. |

| Continuous Flow Design | Allows for low conversion rate studies to isolate intrinsic catalyst selectivity. |

Maximize Your Research Precision with KINTEK

Don’t let equipment limitations skew your catalyst performance data. Backed by expert R&D and manufacturing, KINTEK offers specialized High-Pressure Tube Reactors and laboratory high-temperature furnace systems designed to provide the stable, leak-free environment your CO2 hydrogenation experiments demand. Whether you need to simulate industrial production conditions or perform complex kinetic modeling, our systems are fully customizable to meet your unique lab requirements.

Ready to elevate your chemical engineering results? Contact KINTEK today for a customized solution!

Visual Guide

References

- Shohei Tada, Ryuji Kikuchi. Difference in reaction mechanism between ZnZrO<sub><i>x</i></sub> and InZrO<sub><i>x</i></sub> for CO<sub>2</sub> hydrogenation. DOI: 10.1039/d4cp00635f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is a drop tube furnace? Unlock Insights into Rapid Particle Reactions

- How does the cooling rate of a high-temp tube furnace affect Cu-Zn disordered CZTS layers? Unlock Precise Cation Control

- How did the tube furnace originate and where is it commonly used today? Discover Its Evolution and Modern Applications

- How does the use of a tube furnace for nitrogen-protected annealing affect tin oxide catalysts? Unlock Superior Activity

- What are the main differences in appearance between tube furnaces and box furnaces? Compare Shapes and Uses for Your Lab

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- What is the purpose of performing thermal annealing in vacuum-sealed glass tubes for nickel oxide films?

- What is the function of an industrial tube furnace in studying AlCoCrFeNi coatings? Enhance Material Durability