At their core, dental ceramic furnaces provide the precise thermal control necessary to create strong, lifelike, and biocompatible dental restorations. Their primary benefits are the ability to achieve superior aesthetics through custom staining and glazing, ensure the structural integrity and durability of materials like porcelain, and improve operational efficiency within a dental laboratory or practice.

The decision to use a dental ceramic furnace is not just about acquiring a piece of equipment. It is about gaining direct control over the final quality, fit, and aesthetic outcome of ceramic restorations, which is the cornerstone of high-value dental work.

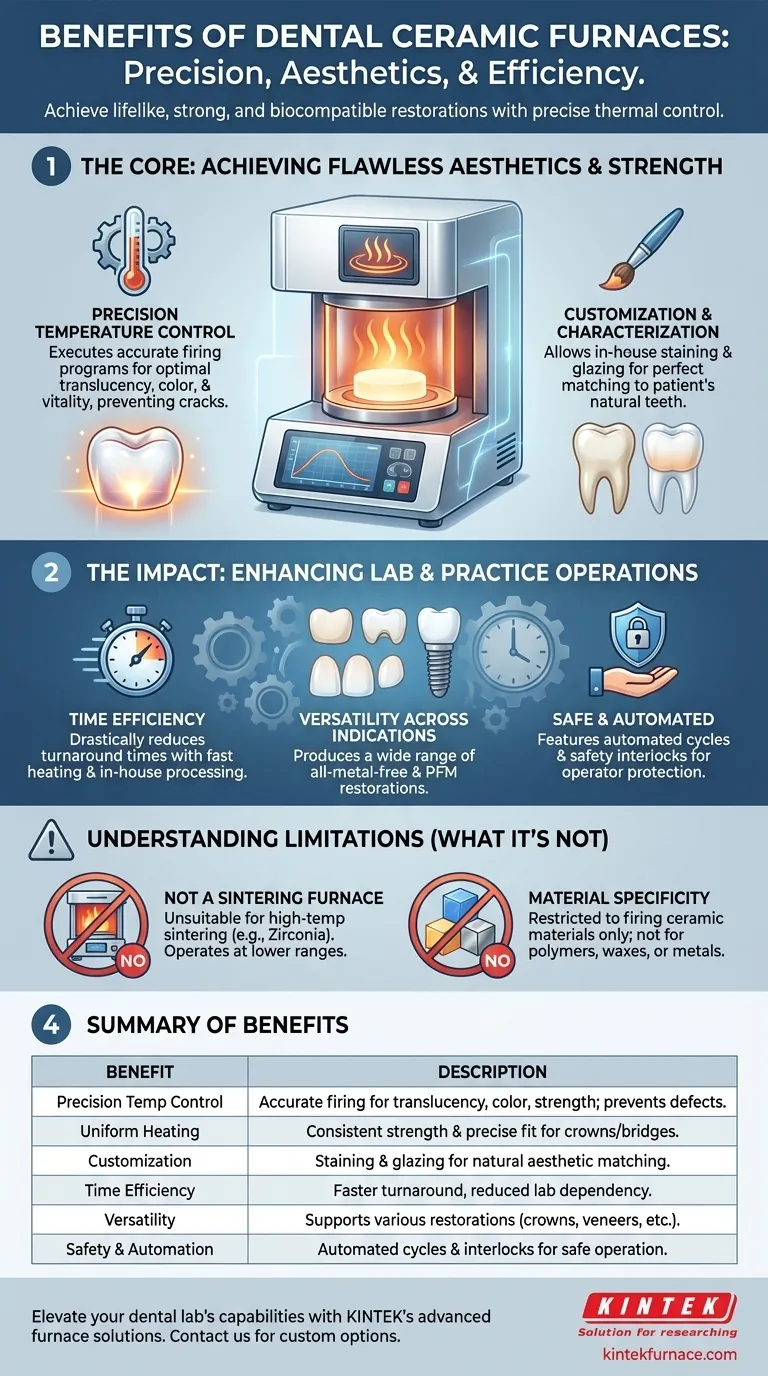

The Core Function: Achieving Flawless Aesthetics and Strength

A ceramic furnace is the final, critical step in fabricating many restorations. Its performance directly dictates the success of the final product.

Precision Temperature Control

The most crucial benefit is the furnace's ability to execute highly accurate firing programs. These automated cycles control heating rates, hold times, and temperature with precision.

This control is essential for developing the optimal translucency, color, and vitality of dental ceramics. It prevents issues like cracking or discoloration that can result from improper firing.

Uniform Heating for Consistency

Modern furnaces use advanced heating elements, often made of Kanthal or Nichrome, to ensure uniform heat distribution throughout the chamber.

This consistency guarantees that the entire restoration—whether a single veneer or a multi-unit bridge—is fired evenly, resulting in predictable strength and a precise fit.

Customization and Characterization

An in-house furnace allows a technician to apply stains and glazes to a restoration and fire it multiple times.

This process of characterization is what allows a crown or veneer to be perfectly matched to the subtle color variations and unique features of a patient's adjacent natural teeth.

The Impact on Lab and Practice Operations

Beyond the quality of the restoration itself, a ceramic furnace has a significant impact on workflow and service offerings.

Enhancing Time Efficiency

Having a furnace in-house drastically reduces turnaround times. Simple adjustments, glaze firings, or even complete fabrication can be done without sending the work to an outside lab.

Many modern units feature fast heating rates and intuitive, touch-display controls, further streamlining the process for technicians and staff.

Versatility Across Indications

A single ceramic furnace can be used to produce a wide range of all-metal-free and porcelain-fused-to-metal (PFM) restorations.

This includes common indications such as:

- Crowns and bridges

- Veneers

- Inlays and onlays

- Prosthetics for dental implants

Safe and Automated Operation

Today's furnaces are designed for usability and safety. They are typically fully automated and feature thermal insulation to keep external surfaces cool.

Critical safety interlocks prevent the door from being opened during a high-temperature cycle, protecting the operator and ensuring the firing program completes without interruption.

Understanding the Trade-offs and Limitations

To use this equipment effectively, it is vital to understand what it is—and what it is not.

Not a Sintering Furnace

A dental ceramic furnace operates at a lower temperature range designed for conventional porcelains and ceramics.

It is unsuitable for the high-temperature sintering process required for materials like zirconia. Sintering requires a different type of furnace designed to reach much higher temperatures for an extended period.

Material Specificity

The furnace's function is restricted to firing ceramic materials. It cannot be used for processing polymers, waxes, or metals, which each require their own specific equipment and processes.

Making the Right Choice for Your Goal

Integrating a ceramic furnace is a strategic decision that depends on your specific objectives.

- If your primary focus is ultimate aesthetic control: An in-house furnace is non-negotiable, as it allows for the nuanced staining and glazing required for high-end cosmetic work.

- If your primary focus is operational efficiency: This equipment dramatically reduces chairside time and dependency on third-party labs for adjustments and simple fabrications.

- If your primary focus is expanding service offerings: A versatile furnace is the key to producing a wide range of valuable ceramic restorations, from single veneers to full-mouth rehabilitations.

Ultimately, a dental ceramic furnace empowers you to deliver a higher standard of care by controlling the variables that matter most.

Summary Table:

| Benefit | Description |

|---|---|

| Precision Temperature Control | Enables accurate firing for optimal translucency, color, and strength, preventing cracks and discoloration. |

| Uniform Heating | Ensures even heat distribution for consistent strength and precise fit of restorations like crowns and bridges. |

| Customization | Allows for staining and glazing to match patient's natural teeth, enhancing aesthetic outcomes. |

| Time Efficiency | Reduces turnaround times with fast heating and in-house processing, minimizing lab dependency. |

| Versatility | Supports fabrication of various restorations, including crowns, veneers, inlays, onlays, and implant prosthetics. |

| Safety and Automation | Features automated cycles and safety interlocks for operator protection and reliable operation. |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental professionals. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Rotary Furnaces, along with deep customization to meet your unique needs for precise ceramic firing. Enhance your efficiency and aesthetic outcomes—contact us today to discuss how our furnaces can benefit your practice!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations