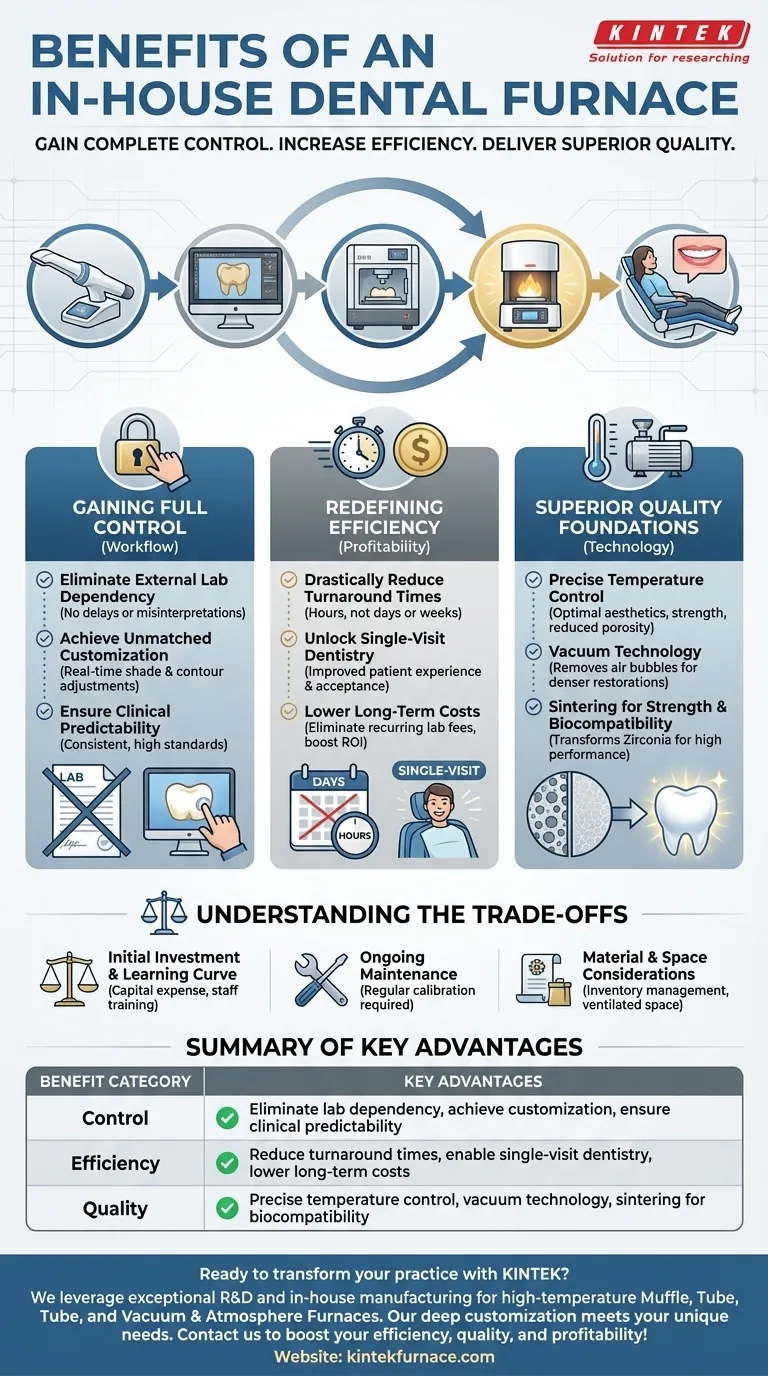

The primary benefits of an in-house dental furnace are gaining complete control over the restorative process, significantly increasing practice efficiency, and delivering a higher standard of clinical quality. By moving production from an external lab to your own office, you transform your workflow, reduce long-term costs, and directly enhance patient care.

An in-house dental furnace is more than an appliance; it represents a strategic shift toward vertical integration. This move empowers a practice to control the entire restoration lifecycle, from digital design to final placement, fundamentally improving speed, cost-effectiveness, and clinical outcomes.

Gaining Full Control Over Your Restorative Workflow

Bringing a furnace in-house shifts the locus of control from an external partner directly to you. This is the most profound benefit, impacting every aspect of your restorative work.

Eliminating Dependency on External Labs

Outsourcing to a laboratory introduces variables in timing, quality, and communication. An in-house furnace brings this critical production step under your direct supervision, eliminating shipping delays and misinterpretations.

Achieving Unmatched Customization

You can make real-time adjustments to shade, contour, and fit without lengthy back-and-forth communication. This ensures each restoration is perfectly tailored to the individual patient, achieving a level of personalization that is difficult with an external lab.

Ensuring Clinical Predictability

With full control over the firing and sintering process, you can consistently produce restorations that meet your exact clinical standards. This confidence eliminates the uncertainty of outsourced quality and leads to more predictable, successful patient outcomes.

Redefining Practice Efficiency and Profitability

Control naturally leads to efficiency. By shortening the production cycle, you can reshape your practice's business model and financial health.

Drastically Reducing Turnaround Times

The most immediate impact is the collapse of the production timeline. A process that once took days or weeks with an external lab—including shipping and potential remakes—can now be accomplished in a matter of hours.

Unlocking Single-Visit Dentistry

An efficient furnace, especially one with a rapid cooling cycle, is a cornerstone of single-visit dentistry. This powerful offering dramatically improves the patient experience, reduces stress, and increases case acceptance.

Lowering Long-Term Costs

While there is an upfront investment, eliminating recurring external lab fees and reducing labor costs associated with coordination creates significant long-term economic benefits and increases overall practice profitability.

The Technical Foundations of Superior Quality

An in-house furnace improves quality not just through control, but through the specific technologies it employs to process modern dental materials.

The Role of Precise Temperature Control

Modern furnaces offer exact temperature management during firing cycles. This precision is critical for achieving optimal aesthetics, strength, and reduced porosity in ceramic materials, leading to more durable and life-like restorations.

The Importance of Vacuum Technology

Many furnaces incorporate a vacuum pump to remove air from the firing chamber. This process eliminates microscopic air bubbles and impurities within the porcelain, resulting in a denser, stronger, and more consistently high-quality restoration.

Sintering for Strength and Biocompatibility

For high-performance materials like zirconia, the furnace performs a critical process called sintering. It heats the soft, milled material to a precise temperature, transforming it into its final, high-strength, and biocompatible state ready for clinical placement.

Understanding the Trade-offs

Objective analysis requires acknowledging the responsibilities that come with this technology.

The Initial Investment and Learning Curve

A dental furnace is a significant capital expense. It also requires that your staff receive proper training to master its operation, material handling protocols, and quality control procedures.

The Need for Ongoing Maintenance

To ensure consistent, high-quality results, the furnace requires regular calibration and maintenance. This is a new operational responsibility that the practice must manage to protect its investment and outcomes.

Material and Space Considerations

Bringing fabrication in-house means you must also manage the inventory of ceramic blocks, powders, and related supplies. The furnace itself also requires dedicated, properly ventilated physical space within the practice.

Making the Right Choice for Your Practice

Deciding to invest in a dental furnace depends on aligning its powerful benefits with your practice's primary strategic goals.

- If your primary focus is patient experience and speed: An in-house furnace is essential for delivering the convenience and powerful marketing appeal of single-visit restorations.

- If your primary focus is clinical quality and control: The ability to customize restorations chairside and oversee the entire process provides unparalleled clinical predictability and superior final results.

- If your primary focus is profitability: Eliminating external lab fees and increasing patient throughput by reducing appointment times can provide a strong and rapid return on your investment.

Ultimately, integrating a dental furnace empowers you to take complete ownership of your practice's restorative outcomes and its future growth.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Control | Eliminate lab dependency, achieve customization, ensure clinical predictability |

| Efficiency | Reduce turnaround times, enable single-visit dentistry, lower long-term costs |

| Quality | Precise temperature control, vacuum technology for strength, sintering for biocompatibility |

Ready to transform your dental practice with advanced furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide dental professionals with high-temperature furnace options like Muffle, Tube, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we meet your unique needs for single-visit dentistry and superior restorative outcomes. Contact us today to discuss how our solutions can boost your efficiency, quality, and profitability!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do ramp rates affect the sintering process? Master Thermal Stress Control for Stronger Restorations

- What is the primary use of a porcelain furnace? Transform Dental Ceramics into Strong, Beautiful Restorations

- What are the primary uses of dental zirconia and what techniques are involved in its sintering process?

- What is the importance of ramp rates in dental sintering furnaces? Ensure Zirconia Restoration Quality and Durability

- What additional functionality do some lab furnaces offer besides sintering? Explore Glazing and Atmosphere Control

- What additional components can be used with dental furnaces for seamless workflows? Boost Efficiency with Digital Integration

- What are the consequences of incorrect temperature settings in dental furnaces? Avoid Costly Dental Restoration Failures

- What are the limitations of zirconia dental furnaces? Higher Costs, Longer Cycles, and Specialized Use