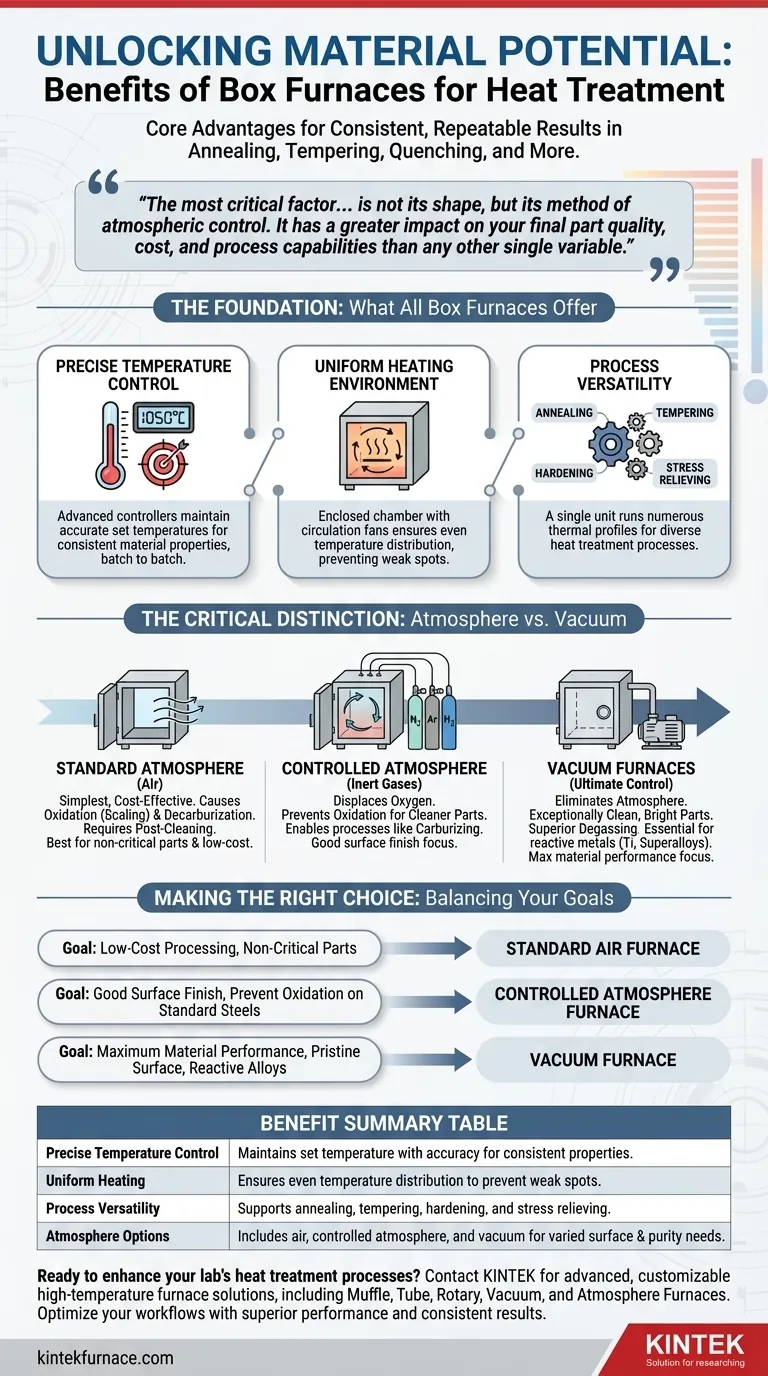

In short, box furnaces offer precise temperature control, uniform heating, and the versatility to perform a wide range of heat treatment processes. These core benefits ensure consistent, repeatable results for processes like annealing, tempering, and quenching, which are essential for modifying a material's final mechanical properties.

The most critical factor in choosing a box furnace is not its shape, but its method of atmospheric control. The decision between a standard air, controlled atmosphere, or vacuum furnace will have a greater impact on your final part quality, cost, and process capabilities than any other single variable.

The Foundation: What All Box Furnaces Offer

At their core, all box furnaces share a fundamental design—an insulated chamber with a door—that provides three primary advantages for material processing.

Precise Temperature Control

Modern box furnaces utilize advanced controllers and thermocouples to maintain a set temperature with remarkable accuracy. This precision is non-negotiable for achieving specific material microstructures and ensuring that results are consistent from batch to batch.

Uniform Heating Environment

The enclosed chamber design, often combined with circulation fans, promotes a uniform temperature throughout the heating zone. This uniformity ensures that the entire workpiece, or an entire batch of parts, receives the same thermal treatment, preventing weak spots or inconsistent hardness.

Process Versatility

A single box furnace can be programmed to run numerous thermal profiles. This allows for a wide variety of heat treatment processes, such as annealing (softening), tempering (increasing toughness), hardening, and stress relieving, all within the same piece of equipment.

The Critical Distinction: Atmosphere vs. Vacuum

While all box furnaces provide the benefits above, their true capability is defined by how they manage the atmosphere inside the chamber. This is the most important distinction for any application.

Standard Atmosphere Furnaces

These are the simplest models, operating with the ambient air that fills the chamber. While cost-effective, heating in the presence of oxygen causes oxidation (scaling) and decarburization (carbon loss) on the surface of steel parts, which may require secondary cleaning operations.

Controlled Atmosphere Furnaces

These furnaces allow for the introduction of specific gases, such as nitrogen, argon, or hydrogen. By displacing the oxygen, these inert or reactive gases can prevent oxidation, resulting in a cleaner part. They can also be used for processes like carburizing, where carbon is intentionally added to the surface.

Vacuum Furnaces: The Ultimate Control

A vacuum furnace is a specialized box furnace that first removes the atmosphere from the chamber. Heating in a vacuum completely eliminates oxidation and decarburization, producing exceptionally clean, bright parts that require no post-process finishing. This pure environment is critical for reactive metals like titanium and high-performance superalloys.

Furthermore, vacuum technology offers superior degassing, pulling trapped impurities like hydrogen out of the material, which can prevent issues like hydrogen embrittlement and improve mechanical properties.

Understanding the Trade-offs

Choosing the right furnace requires balancing desired outcomes with practical constraints. The level of atmospheric control is directly tied to cost, complexity, and performance.

Cost and Complexity

A standard air furnace is the most affordable and simplest to operate. Controlled atmosphere systems add complexity and cost for gas handling, while vacuum furnaces represent the highest initial investment due to their vacuum pumps, robust chamber design, and sophisticated controls.

Surface Finish and Material Purity

If a part's surface finish is not critical or if it will be machined after treatment, a standard furnace may suffice. If a clean, scale-free surface is required, a controlled atmosphere or vacuum furnace is necessary. For the highest purity and performance, particularly with sensitive alloys, vacuum is the only option.

Process Capabilities

While all box furnaces are versatile, vacuum furnaces often integrate rapid cooling (quenching) systems using high-pressure inert gas. This allows a complete hardening and quenching cycle to occur in a single, perfectly controlled environment, minimizing thermal shock and part distortion.

Making the Right Choice for Your Goal

Select your furnace based on the specific requirements of your materials and end product.

- If your primary focus is low-cost processing for non-critical parts: A standard air atmosphere box furnace offers the simplest and most economical solution.

- If your primary focus is a good surface finish and preventing oxidation on standard steels: A controlled atmosphere furnace provides a significant quality improvement over standard air.

- If your primary focus is maximum material performance, a pristine surface, and processing reactive alloys: A vacuum furnace is the definitive choice for achieving superior, repeatable results.

Ultimately, understanding your material's sensitivity to the heating environment is the key to selecting the right tool for the job.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Temperature Control | Maintains set temperature with accuracy for consistent material properties. |

| Uniform Heating | Ensures even temperature distribution to prevent weak spots in workpieces. |

| Process Versatility | Supports annealing, tempering, hardening, and stress relieving in one unit. |

| Atmosphere Options | Includes air, controlled atmosphere, and vacuum for varied surface and purity needs. |

Ready to enhance your lab's heat treatment processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're working with standard steels or reactive alloys, our furnaces deliver superior performance, consistent results, and cost-effective operation. Contact us today to discuss how we can optimize your heat treatment workflows and achieve your material goals!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance