At its core, an induction heater's primary advantages are its exceptional speed, precision, and energy efficiency. Unlike conventional methods that heat a material from the outside, induction heating generates heat directly within the workpiece itself, leading to a faster, cleaner, and more controllable process for any conductive material.

The fundamental benefit of induction heating is not just that it's different, but that it changes where the heating process begins. By generating heat inside the material via an electromagnetic field, it eliminates the inefficiencies and lack of control associated with external heat sources like flames or resistance coils.

How Induction Heating Works

To understand its advantages, you must first grasp its core principle. An induction heater is not a traditional furnace or torch.

The Principle of Induction

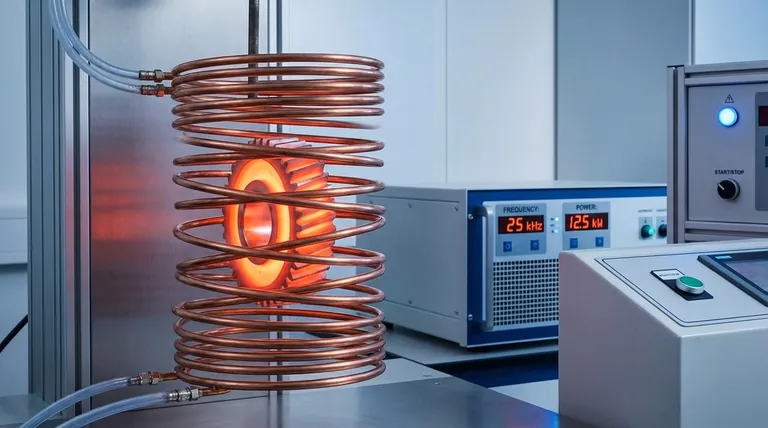

An induction heater uses a copper coil through which a high-frequency alternating current (AC) is passed. This creates a powerful and rapidly changing magnetic field around the coil.

When a conductive workpiece, such as a piece of steel, is placed within this magnetic field, the field induces electrical currents (called eddy currents) to flow inside the metal.

Direct Internal Heat Generation

The resistance of the metal to the flow of these eddy currents generates intense, localized heat. This phenomenon, known as Joule heating, means the material heats itself from the inside out. The coil itself does not get hot, and there is no direct contact or open flame.

Key Advantages Over Traditional Methods

This unique heating mechanism provides several significant advantages over conventional furnaces, ovens, and torches.

Unmatched Speed and Efficiency

Because heat is generated instantly and directly where it's needed, the process is incredibly fast. There is no need to preheat a chamber or wait for heat to slowly transfer from an external source into the part.

This direct generation minimizes thermal inertia and heat loss to the surrounding environment, making induction one of the most energy-efficient heating methods available for industrial applications.

Superior Precision and Repeatability

The heating effect is concentrated where the magnetic field is strongest. By carefully designing the shape of the induction coil, heat can be applied with surgical precision to specific areas of a part.

This allows for targeted hardening of a gear tooth, for example, without altering the properties of the core. Since the power input and cycle time are electronically controlled, the process is perfectly repeatable, ensuring consistent quality from one part to the next.

Enhanced Safety and Workplace Environment

Induction heating eliminates the primary hazards of many industrial heating processes. There is no open flame, which dramatically reduces fire risk.

Furthermore, there are no hot elements or combustion byproducts like smoke and fumes. This creates a much cleaner, cooler, and safer working environment compared to a forge or furnace.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its limitations is critical for making an informed decision.

Material Constraints

The most significant limitation is that induction heating only works directly on electrically conductive materials, primarily metals. It cannot be used to heat plastics, glass, ceramics, or other insulators unless they are paired with a conductive "susceptor" that heats up and transfers heat indirectly.

Initial Capital Investment

Induction heating systems typically have a higher upfront cost than simpler solutions like a gas torch or a basic resistance oven. The power supply and custom-designed coils represent a significant initial investment.

Coil Design and Complexity

The efficiency and precision of the process depend heavily on the design of the induction coil. A coil must be carefully shaped and sized to match the geometry of the workpiece for optimal performance. This can add a layer of complexity, particularly for low-volume runs or irregularly shaped parts.

Making the Right Choice for Your Goal

To determine if induction heating is the correct tool, evaluate your primary objective.

- If your primary focus is high-volume, repeatable production: Induction heating is the superior choice due to its speed, consistency, and potential for automation.

- If your primary focus is precision heat treatment: The ability to localize heat to specific zones of a part makes induction an ideal solution for tasks like surface hardening or brazing complex joints.

- If your primary focus is workplace safety and environmental quality: The absence of flames, fumes, and excessive waste heat makes induction a clear winner.

- If you are working with non-conductive materials or on a very tight budget for a one-off job: Traditional methods like ovens or torches may be more practical and cost-effective.

Ultimately, choosing induction heating is an investment in speed, control, and a safer, more efficient process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed | Instant internal heat generation for rapid processing |

| Precision | Targeted heating with high repeatability |

| Energy Efficiency | Minimal heat loss and direct energy transfer |

| Safety | No open flames, fumes, or hot surfaces |

| Material Suitability | Ideal for conductive metals like steel |

Ready to enhance your industrial heating process with precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our induction heaters and other solutions can optimize your operations for speed, safety, and superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance