At its core, a rotary furnace excels at providing exceptionally uniform heating and high thermal efficiency for drying and roasting powder materials. This is achieved through its fundamental design: a rotating cylindrical chamber that continuously tumbles the material. This constant motion ensures every particle is consistently exposed to the heat source, resulting in a homogenous, high-quality final product.

The central challenge in processing powders is avoiding uneven treatment, where some material gets overheated while other parts remain under-processed. A rotary furnace directly solves this by using mechanical rotation to guarantee uniform heat exposure, leading to superior product consistency, faster processing times, and more efficient energy use.

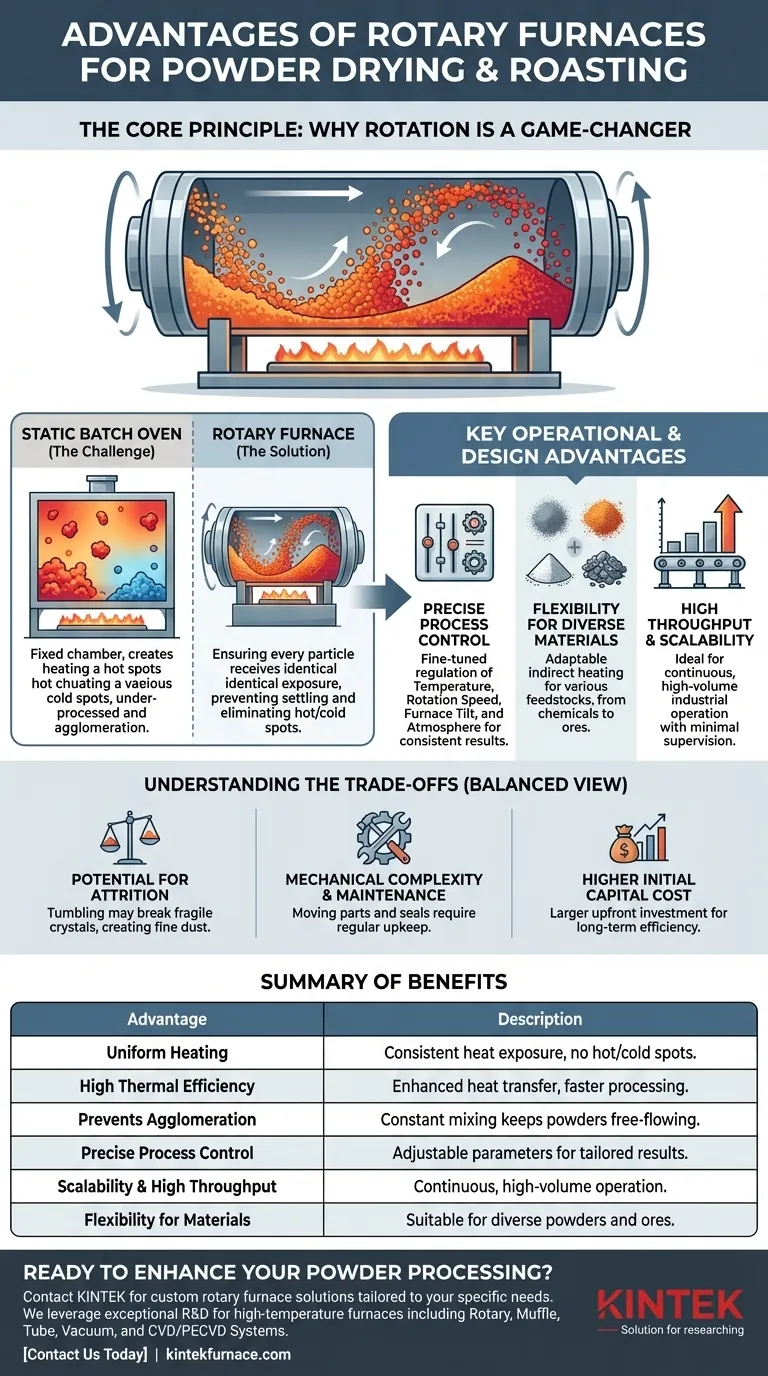

The Core Principle: Why Rotation Is a Game-Changer

The defining advantage of a rotary furnace is not just the heat, but the motion. This dynamic approach diferenças it from static batch ovens and is the source of its primary benefits.

Unmatched Heat Uniformity

The slow, continuous rotation lifts and cascades the powder material inside the heated drum. This action prevents qualquer settling and ensures that particles from the center of the mass are constantly brought to the surface.

As a result, every particle receives virtually identical exposure to the heat, eliminating the hot spots and cold spots common in static systems. This is critical for achieving consistent material properties, whether you are drying, roasting, or performing a chemical reaction like calcination.

Enhanced Heat Transfer Efficiency

The tumbling motion dramatically increases the efficiency of heat transfer. By constantly agitating the powder, the furnace breaks up insulating air pockets and exposes fresh surfaces to the heat source.

This allows the material to reach the target temperature more quickly and with less wasted energy. The result is shorter processing cycles and lower operational costs compared to static methods.

Preventing Material Settling and Agglomeration

Powders, especially fine ones, have a tendency to clump, fuse, or settle when heated statically. This leads to an inconsistent product with undesirable lumps.

The constant mixing action of a rotary furnace keeps the particles separate and free-flowing throughout the process. This prevents agglomeration and ensures a uniform, granular final product.

Key Operational and Design Advantages

Beyond its core principle, the design of a rotary furnace offers several practical benefits for industrial and research applications.

Precise Process Control

Modern rotary furnaces provide fine-tuned control over the key process variables. The temperature, rotation speed, and furnace tilt angle can all be adjusted.

- Rotation Speed: Controls the degree of mixing and the residence time of the material.

- Tilt Angle: Influences how quickly material moves through the furnace in a continuous system, directly controlling processing time.

- Atmosphere: Many units can operate with a controlled atmosphere (e.g., an inert gas like nitrogen), which is essential for processing materials that are sensitive to oxygen.

Flexibility for Diverse Materials

The mechanical principle serviços equally well for a wide variety of feedstocks, from fine chemical powders to mineral ores. Because the heating is indirect (through the drum wall) and uniform, it can be adapted to many different drying and roasting requirements.

High Throughput and Scalability

Rotary furnaces are well-suited for high-volume, continuous operation, making them a cornerstone of many industrial processes. Their heavy-duty construction and simple, reliable mechanics allow them to run for long periods with minimal supervision, maximizing production capacity.

Understanding the Trade-offs

No technology is a universal solution. An objective evaluation requires acknowledging the potential downsides.

Potential for Particle Attrition

The same tumbling action that provides uniform heating can also cause friable or delicate crystals to break down. This mechanical stress, or attrition, can create unwanted fine dust and alter the particle size distribution of the final product. For very sensitive materials, this is a critical factor to consider.

Mechanical Complexity and Maintenance

Compared to a simple static oven, a rotary furnace has more moving parts. The rotating drum, seals, drive motor, and support bearings all require regular inspection and maintenance to ensure long-term reliability. Seals, in particular, are critical for maintaining a controlled atmosphere and can be a point of failure.

Higher Initial Capital Cost

Due to their robust construction and mechanical systems, rotary furnaces typically represent a higher upfront investment than simpler batch ovens. The return on this investment is realized through higher throughput, greater energy efficiency, and superior product quality over the long term.

Making the Right Choice for Your Powder

To select the right thermal processing technology, you must align the equipment's strengths with your primary goal.

- If your primary focus is product consistency and quality: The uniform heating of a rotary furnace is its single greatest advantage, eliminating hot spots and ensuring every particle is processed identically.

- If your primary focus is operational efficiency and throughput: The enhanced heat transfer and potential for continuous operation make it ideal for high-volume production with lower energy costs per unit.

- If your primary focus is processing delicate or friable materials: You must carefully evaluate the risk of particle attrition from the tumbling action and consider features like adjustable rotation speeds.

By understanding its fundamental principle of dynamic heating, you can determine if a rotary furnace is the optimal tool to achieve your specific processing goals.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Ensures every particle is consistently exposed to heat, eliminating hot spots and cold spots for homogenous results. |

| High Thermal Efficiency | Tumbling action enhances heat transfer, reducing energy use and shortening processing times. |

| Prevents Agglomeration | Constant mixing keeps powders free-flowing, preventing clumping and ensuring a uniform final product. |

| Precise Process Control | Adjustable rotation speed, tilt angle, and atmosphere for tailored drying and roasting processes. |

| Scalability and High Throughput | Ideal for continuous, high-volume operations with minimal supervision, boosting production capacity. |

| Flexibility for Materials | Suitable for diverse powders, from fine chemicals to mineral ores, with indirect heating methods. |

Ready to enhance your powder processing with a custom rotary furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're focused on achieving superior product consistency, improving operational efficiency, or scaling up your processes, we're here to help. Contact us today to discuss how our expertise can benefit your laboratory or industrial setup!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency