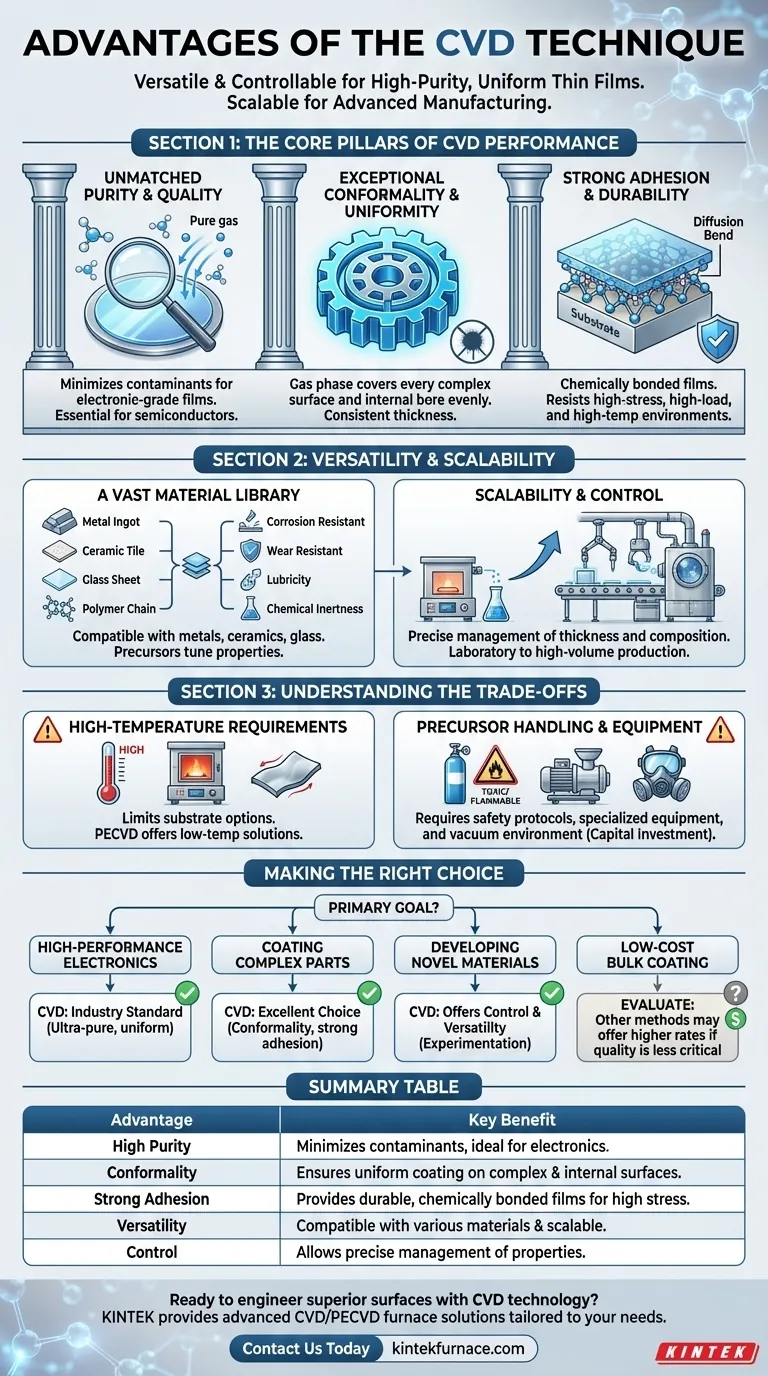

At its core, Chemical Vapor Deposition (CVD) is a highly versatile and controllable process for creating thin films. Its primary advantages are the ability to produce exceptionally high-purity coatings with uniform thickness, even over large or geometrically complex surfaces, making it a scalable and cost-effective solution for advanced manufacturing.

The true power of CVD lies not just in applying a coating, but in fundamentally engineering a surface. Its ability to create a highly uniform, pure, and strongly bonded film on virtually any shape makes it an indispensable technology for industries from semiconductors to aerospace.

The Core Pillars of CVD Performance

The advantages of CVD stem from its fundamental process: using chemical reactions from gaseous precursors to deposit a solid film onto a substrate. This "bottom-up" synthesis method provides a level of control that is difficult to achieve with other techniques.

Unmatched Purity and Quality

CVD uses highly pure precursor gases as its source material. This process inherently minimizes the introduction of contaminants, resulting in films with exceptionally high purity.

This level of purity is non-negotiable in applications like semiconductor manufacturing, where even minute impurities can ruin the electronic properties of a device.

Exceptional Conformality and Uniformity

One of CVD's most significant advantages is its conformality. Because the deposition occurs from a gas phase, the precursor molecules can reach every part of a substrate's surface, regardless of its complexity.

This allows for a perfectly uniform coating on intricate shapes, internal bores, and patterned substrates. Think of it as the difference between spray-painting an object (where some surfaces get more paint than others) and enveloping it in a fog that condenses evenly everywhere.

This capability ensures consistent thickness and performance across the entire part.

Strong Adhesion and Durability

CVD films are not merely sitting on top of the substrate; they are chemically bonded to it. The process often creates a diffusion bond at the interface, where atoms from the film and the substrate intermingle.

This results in exceptional adhesion and a coating that remains intact even in high-stress, high-load, or high-temperature environments. This durability is critical for protective coatings in the aerospace, automotive, and tooling industries.

Versatility Across Materials and Applications

CVD is not a single process but a family of techniques adaptable to a wide range of materials and end-goals. This flexibility makes it a powerful tool for both industrial production and cutting-edge research.

A Vast Material Library

The CVD process is compatible with a wide variety of base materials, including metals, metal alloys, ceramics, and glass.

Furthermore, the precursor gases can be precisely chosen and mixed to deposit a huge range of materials. By tuning the chemistry, you can optimize the final film for specific properties like corrosion resistance, wear resistance, lubricity, or chemical inertness.

Scalability and Control

The process is highly controllable, allowing for precise management of film thickness, composition, and even porosity.

This control is also scalable. The same fundamental principles that work on a small laboratory sample can be applied to large-area deposition for industrial-scale manufacturing, making CVD a cost-effective solution for high-volume production.

Understanding the Trade-offs

While powerful, CVD is not a universal solution. Understanding its operational requirements is key to deciding if it's the right choice.

High-Temperature Requirements

Many traditional CVD processes require very high temperatures to drive the necessary chemical reactions. This can limit the types of substrate materials that can be used, as some may deform or be damaged by the heat.

However, variants like Plasma-Enhanced CVD (PECVD) have been developed to allow for low-temperature deposition, making the process compatible with more sensitive substrates like polymers.

Precursor Handling and Equipment

The precursor gases used in CVD can be toxic, flammable, or corrosive, necessitating significant safety protocols and specialized handling equipment.

Additionally, many CVD processes require a vacuum environment to ensure purity and control the reaction. The high-temperature furnaces and vacuum chambers represent a significant capital investment.

Making the Right Choice for Your Application

Selecting a deposition technique depends entirely on your primary goal. CVD excels where quality, conformality, and material properties are paramount.

- If your primary focus is high-performance electronics: CVD is the industry standard due to its unparalleled ability to deposit ultra-pure, uniform films.

- If your primary focus is coating complex parts for extreme environments: CVD is an excellent choice because its conformality and strong adhesion provide durable protection on any surface.

- If your primary focus is developing novel materials: CVD offers the control and versatility needed to experiment with different compositions and structures for research purposes.

- If your primary focus is low-cost, simple bulk coating: You should evaluate if the high quality of CVD is necessary, as other methods might offer higher deposition rates for less critical applications.

Ultimately, CVD is the enabling technology for creating advanced surfaces with precisely engineered properties.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High Purity | Minimizes contaminants for superior film quality, ideal for electronics |

| Conformality | Ensures uniform coating on complex shapes and internal surfaces |

| Strong Adhesion | Provides durable, chemically bonded films for high-stress environments |

| Versatility | Compatible with various materials and scalable for industrial use |

| Control | Allows precise management of thickness, composition, and properties |

Ready to engineer superior surfaces with CVD technology? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored CVD solutions can enhance your material performance and accelerate your research or production!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition