In terms of efficiency, Molybdenum Disilicide (MoSi2) heating elements are highly effective due to their ability to heat up extremely fast while consuming less power. Their efficiency is further enhanced by their capacity to emit radiant heat, which directly and rapidly heats materials, and their stable electrical resistance, which ensures consistent, predictable performance over a long service life.

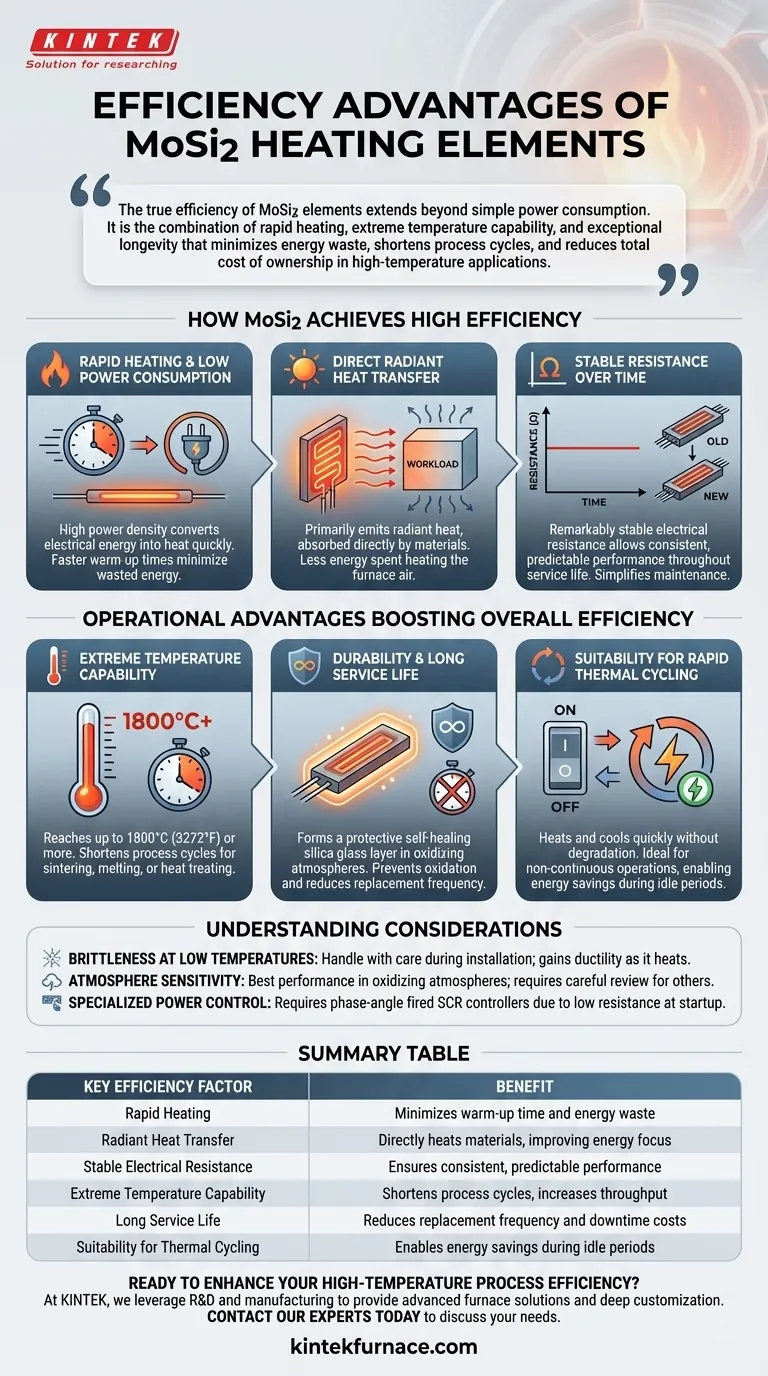

The true efficiency of MoSi2 elements extends beyond simple power consumption. It is the combination of rapid heating, extreme temperature capability, and exceptional longevity that minimizes energy waste, shortens process cycles, and reduces total cost of ownership in high-temperature applications.

How MoSi2 Elements Achieve High Efficiency

The efficiency of a heating element is not just about its power rating, but how effectively it converts electricity into usable heat and how that performance holds up over time. MoSi2 elements excel in several key areas.

Rapid Heating and Low Power Consumption

MoSi2 elements have a high power density, often called watt loading. This allows them to convert electrical energy into heat very quickly.

This rapid heating capability means the furnace reaches its target temperature faster, minimizing the time and energy wasted during the initial warm-up phase.

Direct Radiant Heat Transfer

MoSi2 elements primarily operate by emitting radiant heat. Unlike convection, which heats the air, radiant energy travels in a straight line and is absorbed directly by the materials inside the furnace.

This direct method of heat transfer is fundamentally more efficient, as it spends less energy heating the furnace atmosphere and focuses energy directly on the workload.

Stable Resistance Over Time

A key feature of MoSi2 is its remarkably stable electrical resistance, which does not significantly change as the elements age.

This stability ensures that the power output remains consistent and predictable throughout the element's life. It also allows you to connect new elements in series with older ones without causing performance issues, simplifying maintenance and reducing costs.

Operational Advantages That Boost Overall Efficiency

Beyond electrical efficiency, MoSi2 elements offer practical advantages that make the entire heating process more efficient and cost-effective.

Extreme Temperature Capability

MoSi2 elements are capable of reaching the highest operating temperatures among common metallic and ceramic heating elements, often up to 1800°C (3272°F) or more.

Operating at higher temperatures can dramatically shorten the time required for processes like sintering, melting, or heat treating, which directly improves production throughput and overall process efficiency.

Durability and Long Service Life

These elements are known for their exceptionally long life expectancy, especially when operated continuously in oxygen-rich atmospheres. They form a protective self-healing layer of silica glass on their surface that prevents further oxidation.

Longer life reduces the frequency of replacement, minimizing furnace downtime and maintenance labor costs, which contributes significantly to long-term economic efficiency.

Suitability for Rapid Thermal Cycling

MoSi2 elements can be heated and cooled quickly without suffering degradation. This makes them ideal for applications that do not run continuously.

The ability to turn the furnace off or lower the temperature during idle periods, then rapidly return to operating temperature when needed, can result in substantial energy savings.

Understanding the Trade-offs and Considerations

While highly efficient, MoSi2 elements are a specialized component. Their optimal performance is dependent on the right application and operating conditions.

Brittleness at Low Temperatures

MoSi2 elements are a ceramic composite and are very brittle at room temperature. They must be handled with care during installation to avoid fracture. They gain ductility as they heat up.

Atmosphere Sensitivity

These elements perform best in an oxidizing atmosphere, where their protective silica layer can form and regenerate. Their use in reducing or other specific atmospheres can lead to degradation and requires careful engineering review.

Specialized Power Control

Due to their low resistance at room temperature and significant increase in resistance with heat, they require sophisticated, phase-angle fired SCR power controllers to manage the high inrush current during startup.

Making the Right Choice for Your Application

Selecting the right heating element requires matching its characteristics to your process goals.

- If your primary focus is maximum process speed and temperature: MoSi2 is an ideal choice due to its unparalleled rapid heating and high-temperature capabilities.

- If your primary focus is long-term cost and reliability in continuous use: MoSi2's long service life, stable performance, and low power consumption make it a superior economic decision for high-temperature oxidizing environments.

- If you require frequent thermal cycling: The ability of MoSi2 to heat and cool quickly without damage makes it highly efficient for non-continuous furnace operations.

Ultimately, leveraging the distinct advantages of MoSi2 elements allows you to design a faster, more reliable, and more energy-efficient high-temperature process.

Summary Table:

| Key Efficiency Factor | Benefit |

|---|---|

| Rapid Heating | Minimizes warm-up time and energy waste |

| Radiant Heat Transfer | Directly heats materials, improving energy focus |

| Stable Electrical Resistance | Ensures consistent, predictable performance |

| Extreme Temperature Capability (up to 1800°C+) | Shortens process cycles, increases throughput |

| Long Service Life | Reduces replacement frequency and downtime costs |

| Suitability for Thermal Cycling | Enables energy savings during idle periods |

Ready to enhance your high-temperature process efficiency with MoSi2 heating elements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you design a faster, more reliable, and energy-efficient process. Contact our experts today to discuss your application needs and discover the right solution for your lab.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability