At their core, low vacuum atmosphere furnaces offer a powerful combination of reduced operational costs, faster processing times, and simpler maintenance. By operating at a negative pressure that is not a "hard" or high vacuum, they create a controlled environment that is sufficient for many industrial heat treatment processes without the expense and complexity of high-vacuum systems.

A low vacuum furnace represents a strategic compromise. It delivers most of the key benefits of a controlled atmosphere—like preventing oxidation—while keeping costs down and maximizing production throughput, making it a workhorse for a wide range of industrial applications.

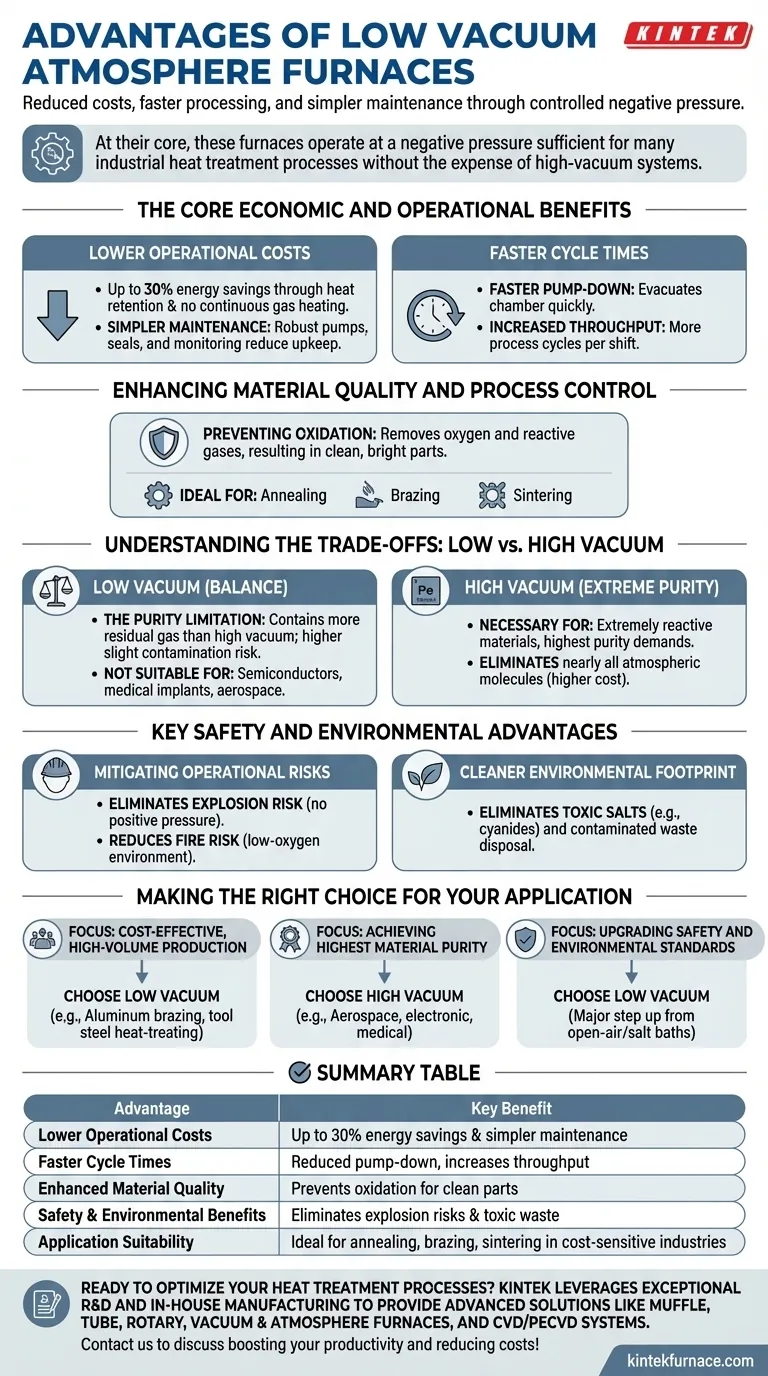

The Core Economic and Operational Benefits

The primary appeal of low vacuum furnaces lies in their ability to improve a facility's bottom line and operational efficiency. They strike a balance between performance and practicality.

Lower Operational Costs

These furnaces are designed for high energy efficiency, sometimes achieving up to 30% energy savings over conventional methods. This is accomplished through superior heat retention and the elimination of the need to constantly heat a flow of protective gas.

Lower costs are also realized through simpler maintenance. The vacuum requirements are less stringent than in high-vacuum systems, meaning the pumps, seals, and monitoring equipment are less complex and more robust, reducing long-term upkeep expenses.

Faster Cycle Times

A significant advantage in a production environment is a faster pump-down time. Because the system does not need to achieve an ultra-high vacuum level, the time required to evacuate the chamber is much shorter, allowing for more process cycles per shift.

Enhancing Material Quality and Process Control

Moving beyond cost, these furnaces provide a superior environment for treating materials compared to open-air or simple inert gas furnaces.

Preventing Oxidation

By removing the majority of oxygen and other reactive gases from the chamber, a low vacuum furnace effectively prevents oxidation and other unwanted surface reactions on the workpiece. This results in clean, bright parts that often require no post-process cleaning.

This controlled environment is ideal for processes like annealing, brazing, and sintering, where chemical purity and surface integrity are critical to the final component's performance.

Understanding the Trade-offs: Low vs. High Vacuum

While advantageous, low vacuum is not the solution for every application. Understanding its limitations is key to making an informed decision.

The Purity Limitation

The primary trade-off is purity. A low vacuum environment still contains more residual gas molecules than a high vacuum one. This presents a higher risk of slight contamination.

This makes low vacuum furnaces unsuitable for applications with extreme purity requirements, such as manufacturing semiconductors, medical implants, or critical aerospace components where even minuscule contamination can lead to failure.

When to Choose High Vacuum

A high vacuum furnace is necessary when the material being processed is extremely reactive or when the final application demands the absolute highest level of material purity. The added cost and complexity are justified by the need to eliminate nearly all atmospheric molecules.

Key Safety and Environmental Advantages

Compared to older heat treatment technologies, low vacuum furnaces offer significant improvements in workplace safety and environmental responsibility.

Mitigating Operational Risks

Operating at a negative pressure eliminates the risk of explosion that can exist with positive-pressure vessels. Furthermore, the low-oxygen environment dramatically reduces the risk of fire, making the entire operation inherently safer.

A Cleaner Environmental Footprint

These furnaces provide a solution to the environmental problems associated with older methods. They eliminate the need for toxic salts (like cyanides) used in salt bath heat treating, which in turn gets rid of the challenge of disposing of contaminated waste and fixtures.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your material, your process, and your production goals.

- If your primary focus is cost-effective, high-volume production: A low vacuum furnace is an excellent choice for processes like brazing aluminum automotive parts or heat-treating tool steels.

- If your primary focus is achieving the highest material purity: You must invest in a high vacuum system to meet the demands of sensitive aerospace, electronic, or medical applications.

- If your primary focus is upgrading safety and environmental standards: A low vacuum furnace is a major step up from conventional methods like open-air heating or salt baths.

Ultimately, choosing the right furnace is about precisely matching the level of atmospheric control to the specific needs of your material and process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Lower Operational Costs | Up to 30% energy savings and simpler maintenance |

| Faster Cycle Times | Reduced pump-down time increases production throughput |

| Enhanced Material Quality | Prevents oxidation for clean, bright parts |

| Safety & Environmental Benefits | Eliminates explosion risks and toxic waste |

| Application Suitability | Ideal for annealing, brazing, and sintering in cost-sensitive industries |

Ready to optimize your heat treatment processes with a low vacuum furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering energy efficiency, faster cycles, and enhanced safety. Contact us today to discuss how we can boost your productivity and reduce costs!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality