At its core, a ceramic dental furnace provides the precise temperature control required to create strong, durable, and aesthetically superior dental restorations. This precision ensures uniform heating, which is essential for achieving the lifelike translucency and accurate color matching expected in modern dentistry. The result is a highly predictable and efficient workflow, reducing the need for costly remakes and adjustments.

A ceramic dental furnace is not merely an oven; it is a precision instrument. Its primary value lies in translating a technician's skill into a flawless final product by providing unparalleled control over the firing process, which dictates the restoration's ultimate aesthetic and structural integrity.

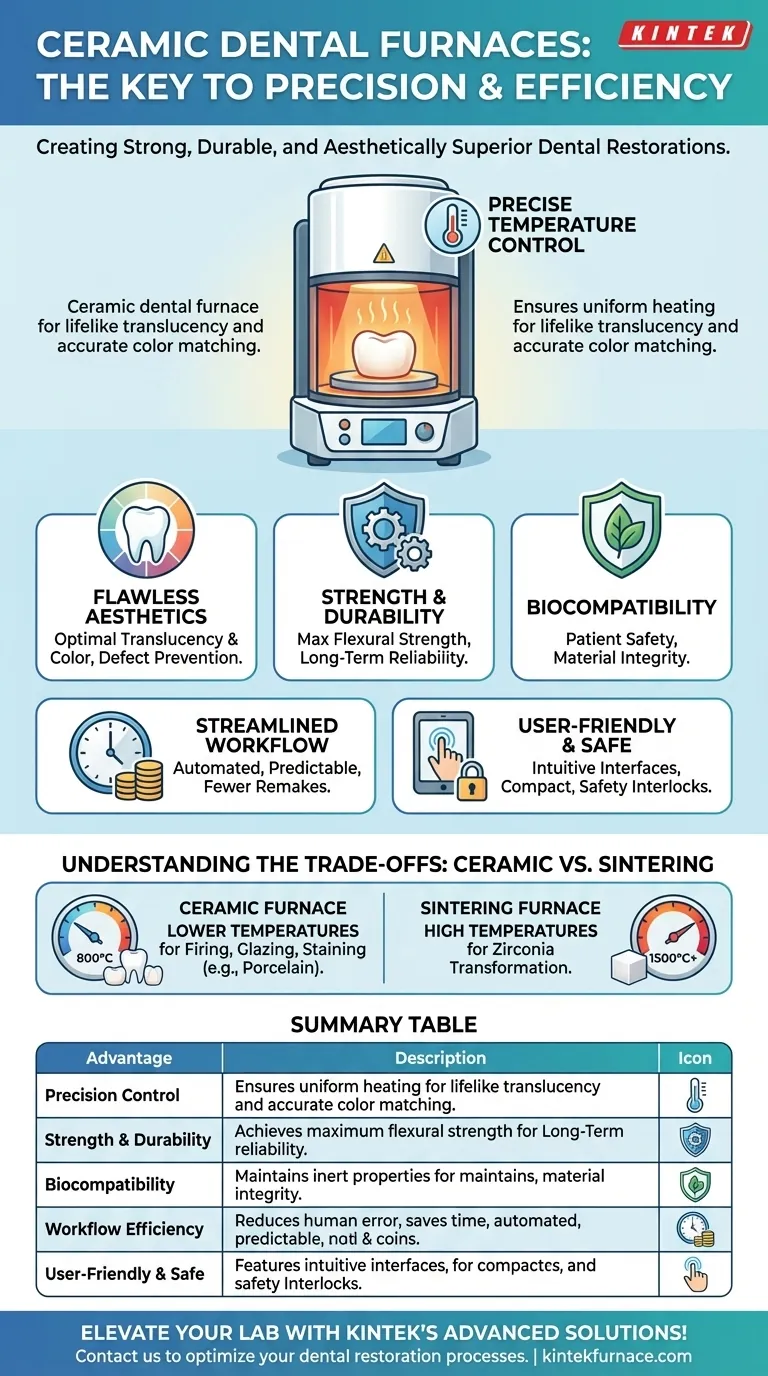

The Foundation of Quality: Unpacking the Core Advantages

The true advantage of a modern ceramic furnace is its ability to consistently produce high-quality results. This is achieved through a synthesis of precise control, predictable automation, and material-specific programming.

Achieving Flawless Aesthetics Through Precision Control

The most significant benefit is the furnace's ability to execute highly accurate firing cycles. This directly impacts the final look of the restoration.

Precise temperature management and uniform heating are essential for developing the optimal translucency and color in dental porcelain. This control ensures the final crown or veneer blends seamlessly with natural teeth.

This precision also prevents common defects like cracks or bubbles, ensuring a smooth, high-quality surface finish on every restoration.

Ensuring Strength and Durability

Aesthetics must be matched by longevity. The firing process is what gives a ceramic restoration its final strength.

By adhering to the ceramic manufacturer's recommended firing schedules, the furnace ensures the material reaches its maximum flexural strength and durability.

This controlled process produces consistent and predictable results, leading to restorations that can withstand the forces of mastication over the long term.

Enhancing Biocompatibility

Dental ceramics are valued for being inert and highly biocompatible.

Proper firing in a quality furnace ensures the material is fully processed, maintaining its biocompatible properties and ensuring patient safety.

Streamlining the Lab Workflow

Beyond the quality of the individual restoration, a ceramic furnace brings significant efficiency to the dental lab or in-office practice.

Gaining Predictability and Consistency

Modern furnaces are fully automated, with pre-set programs for a wide range of ceramic materials.

This automation reduces the chance of human error, leading to highly consistent results from one case to the next. The outcome is fewer adjustments and remakes, which is a major source of lost time and profit.

Improving Time and Cost-Effectiveness

By delivering predictable results, these furnaces save valuable chair time for dentists and bench time for technicians.

For any practice or lab that produces a significant volume of porcelain-fused-to-metal (PFM) or all-ceramic restorations, a dedicated furnace is a highly cost-effective investment.

Prioritizing User-Friendly Operation and Safety

Today's furnaces are designed with the user in mind, featuring compact footprints and intuitive, user-friendly interfaces.

They also incorporate critical safety features, such as thermal insulation to keep external surfaces cool and safety interlocks that prevent the chamber from being opened during a high-temperature cycle.

Understanding the Trade-offs: Ceramic vs. Sintering

To truly understand the advantage of a ceramic furnace, you must also understand its specific role and limitations. It is a specialized tool, not a one-size-fits-all solution.

The Specialization of Ceramic Furnaces

Ceramic furnaces are designed to operate at the lower temperatures required for firing, glazing, and staining conventional dental porcelains and ceramics.

They are the go-to instrument for creating crowns, veneers, bridges, and other restorations from materials like feldspathic porcelain or lithium disilicate (for glazing and characterizing).

The Limitation: Not for High-Temperature Sintering

A critical distinction is that a ceramic furnace cannot be used for sintering materials like zirconia.

Sintering requires much higher temperatures (often above 1500°C) to transform the chalky, pre-sintered zirconia into a dense, high-strength final framework. This process demands a different piece of equipment: a sintering furnace.

The Rise of Combination Furnaces

Some modern units, known as combination or "combi" furnaces, are designed to both fire conventional ceramics and press ceramic ingots. This adds versatility for labs that work with pressable ceramic systems, allowing them to perform two functions with a single machine.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on the type of restorations you produce.

- If your primary focus is aesthetic porcelain restorations (veneers, PFM, layering): A dedicated ceramic furnace is essential for achieving the highest level of quality and consistency.

- If your primary focus is high-strength monolithic zirconia restorations: You require a sintering furnace; a ceramic furnace cannot perform this function.

- If your primary focus is a mixed-material workflow: You may need both a ceramic furnace and a sintering furnace, or you might consider a combination press-and-fire furnace to maximize versatility.

Ultimately, investing in a quality ceramic furnace is an investment in your ability to predictably and efficiently deliver exceptional restorations.

Summary Table:

| Advantage | Description |

|---|---|

| Precision Control | Ensures uniform heating for optimal translucency, color matching, and defect prevention. |

| Strength & Durability | Achieves maximum flexural strength and long-term reliability through controlled firing cycles. |

| Biocompatibility | Maintains inert properties for patient safety and material integrity. |

| Workflow Efficiency | Reduces human error, saves time, and lowers costs with automated, predictable results. |

| User-Friendly & Safe | Features intuitive interfaces, compact designs, and safety interlocks for easy operation. |

Elevate your dental lab's capabilities with KINTEK's advanced ceramic furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental professionals. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by deep customization to meet your unique experimental needs. Whether you're focused on aesthetic porcelain restorations or mixed-material workflows, our furnaces deliver precision, efficiency, and durability. Contact us today to discuss how we can optimize your dental restoration processes and boost your lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab