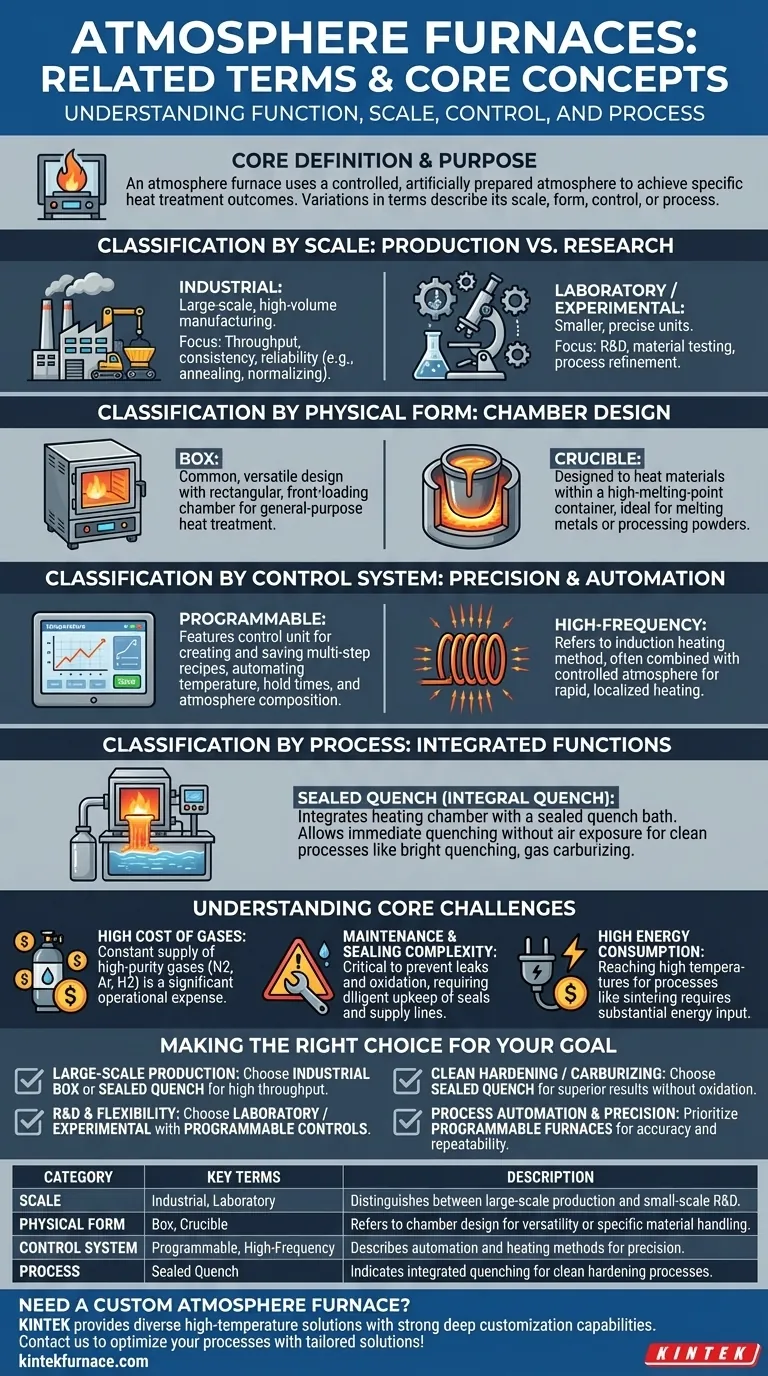

At its core, an atmosphere furnace is any furnace that uses a controlled, artificially prepared atmosphere to achieve a specific outcome during heat treatment. The terms associated with it describe variations in its scale, physical form, control system, or the specific process it's designed to perform, such as industrial, laboratory, box, programmable, and sealed quench furnaces.

The various names for atmosphere furnaces are not interchangeable. They provide a blueprint for the furnace's intended use—whether for large-scale industrial production, precise laboratory research, or a specific chemical process like carburizing.

Unpacking the Terminology: Function, Scale, and Control

To understand the landscape of atmosphere furnaces, it's best to categorize the related terms by what they describe: the furnace's size and application, its physical design, or its method of control.

Classification by Scale: Industrial vs. Laboratory

The most fundamental distinction is between furnaces built for production and those built for research.

Industrial atmosphere furnaces are large-scale systems designed for high-volume manufacturing. Their primary focus is throughput, consistency, and reliability in processes like annealing or normalizing metals.

Laboratory or experimental atmosphere furnaces are smaller, more precise units. They are used in research and development (R&D) to test new materials, refine heat treatment processes, and analyze material properties on a small scale.

Classification by Physical Form: Box vs. Crucible

The physical construction of the furnace chamber often gives the equipment its name.

A box atmosphere furnace is a common design featuring a rectangular, front-loading chamber. This versatile shape is suitable for a wide range of general-purpose heat treatment applications for various parts and materials.

A crucible atmosphere furnace is designed to heat materials within a crucible, a container made from a material with a very high melting point. This is ideal for melting metals or processing powders and small components that cannot be placed directly on a furnace hearth.

Classification by Control System: Programmable & High-Frequency

Modern furnaces are defined by the sophistication of their control systems.

A programmable atmosphere furnace features a control unit that allows operators to create and save multi-step recipes. This automates the process, ensuring precise control over temperature ramp rates, hold times, and atmosphere composition, which is critical for repeatability.

A high-frequency furnace refers to the heating method, which uses induction. While not exclusively used for atmosphere control, high-frequency induction can be combined with a controlled atmosphere for extremely rapid and localized heating.

Classification by Process: The Role of Sealed Quench

Some furnaces are named for the specific, integrated process they perform.

The sealed quench furnace (also called an integral quench furnace) is a prime example. This design integrates the heating chamber with a sealed oil or salt quench bath. It allows a part to be heated in a controlled atmosphere and then immediately quenched without exposure to air, enabling clean processes like bright quenching, gas carburizing, and carbonitriding.

Understanding the Core Challenges

While powerful, atmosphere furnaces introduce complexities and costs that must be managed. Understanding these trade-offs is critical for successful operation.

The High Cost of Gases

Maintaining a specific atmosphere requires a constant supply of gases like nitrogen, argon, or hydrogen. The cost of these high-purity gases can be a significant operational expense, especially in large-scale industrial applications.

Maintenance and Sealing Complexity

The entire purpose of the furnace is to maintain a pure, controlled environment. Any leaks compromise the process, leading to oxidation and failed parts. Ensuring the furnace remains perfectly sealed requires diligent maintenance of door seals, gaskets, and gas supply lines.

High Energy Consumption

Reaching the high temperatures required for processes like annealing or sintering consumes a substantial amount of energy. This, combined with the cost of process gases, makes energy efficiency a key consideration in furnace selection and operation.

Making the Right Choice for Your Goal

Selecting the correct type of atmosphere furnace depends entirely on your primary objective, whether it's production volume, research flexibility, or process specificity.

- If your primary focus is large-scale production: You need an industrial box or sealed quench furnace built for high throughput and process repeatability.

- If your primary focus is research and development: A flexible laboratory or experimental furnace, likely with programmable controls, is the ideal choice for material testing and process discovery.

- If your primary focus is clean hardening or case hardening: A sealed quench furnace is specifically designed for processes like bright quenching and carburizing, offering superior results by preventing oxidation.

- If your primary focus is process automation and precision: Prioritize furnaces with programmable and controllable temperature features, regardless of scale, to ensure accuracy and repeatability.

By understanding these distinctions, you can select a furnace that precisely matches your material processing objectives.

Summary Table:

| Category | Key Terms | Description |

|---|---|---|

| Scale | Industrial, Laboratory | Distinguishes between large-scale production and small-scale R&D furnaces. |

| Physical Form | Box, Crucible | Refers to chamber design for versatility or specific material handling. |

| Control System | Programmable, High-Frequency | Describes automation and heating methods for precision. |

| Process | Sealed Quench | Indicates integrated quenching for clean hardening processes like carburizing. |

Need a custom atmosphere furnace for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can optimize your heat treatment processes with tailored solutions!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance