In essence, a programmable firing cycle is the automated, digitally-controlled recipe a modern porcelain furnace follows to fire dental ceramics. These cycles precisely manage every stage of the heating and cooling process—including temperature ramp rates, hold times, and target temperatures—to ensure the final restoration achieves its intended strength, color, and translucency. It transforms the firing process from a manual art into a repeatable science.

Programmable cycles are the cornerstone of modern dental labs. They replace the variability of manual control with digital precision, guaranteeing that every ceramic restoration consistently meets specific material requirements and esthetic goals.

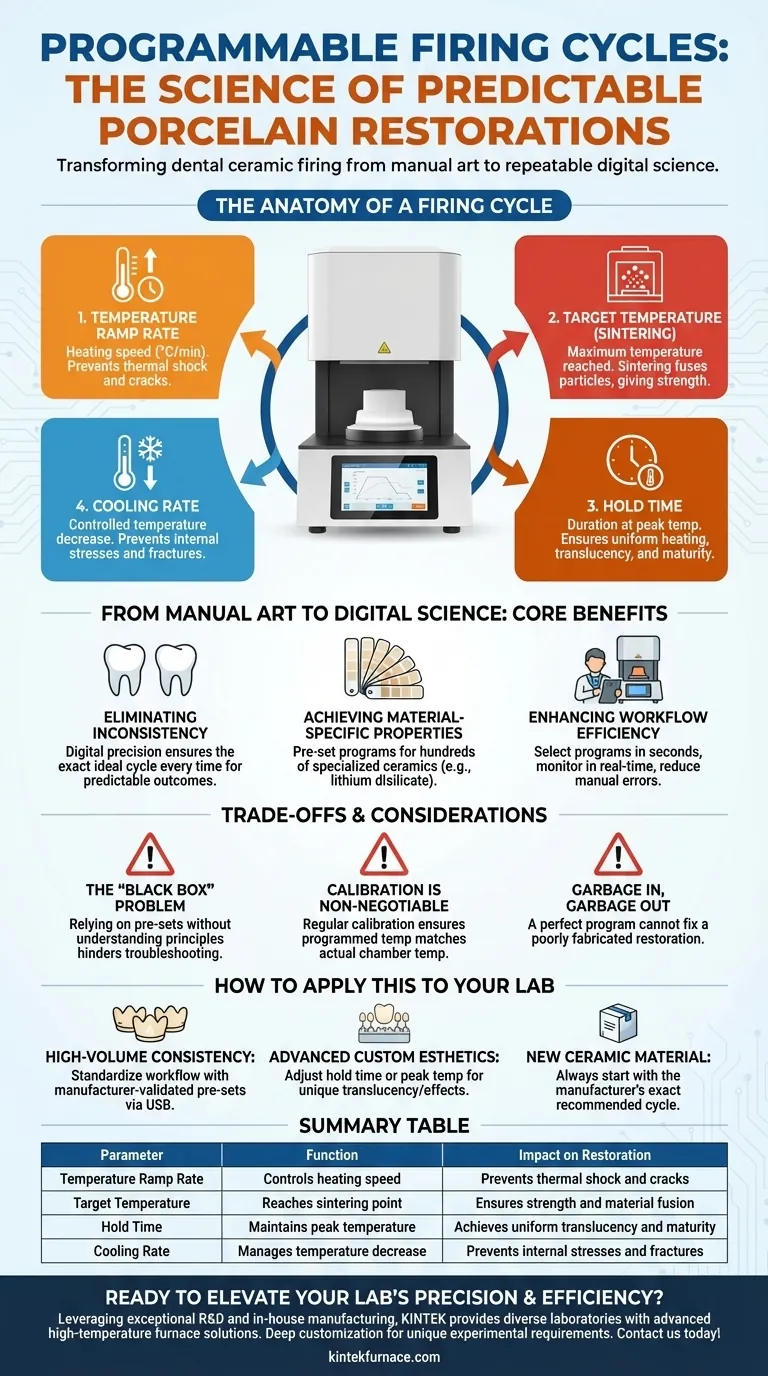

The Anatomy of a Firing Cycle: What Are You Controlling?

A firing cycle is not a single setting but a sequence of carefully controlled parameters. Understanding these variables is key to understanding why programmability is so crucial for high-quality results.

The Temperature Ramp Rate

This is the speed at which the furnace chamber heats up, measured in degrees Celsius per minute. A controlled ramp rate prevents thermal shock, which can cause cracks in the porcelain. Different materials and restoration thicknesses require different ramp speeds.

The Target Temperature (Sintering)

This is the maximum temperature the cycle will reach. At this peak temperature, the ceramic particles undergo sintering—they fuse together, densifying the material and giving it strength. The exact temperature is critical; being off by even a few degrees can ruin the restoration's properties.

The Hold Time

Once the target temperature is reached, it is held constant for a specific duration. This "hold time" ensures that the entire restoration is heated uniformly and that the sintering process is completed thoroughly. It is essential for achieving the desired translucency and maturing the ceramic.

The Cooling Rate

Just as important as heating, the cooling phase must also be controlled. A gradual, programmed decrease in temperature prevents internal stresses from building up, which could lead to fractures long after the restoration has been placed.

From Manual Art to Digital Science: The Core Benefit

Programmable furnaces solve the fundamental problem of inconsistency that plagued earlier, manually operated equipment. This digital control provides several distinct advantages.

Eliminating Inconsistency

Manual control is subject to human error and variation. Digital programmability ensures that the exact same ideal firing cycle is executed perfectly every single time, leading to predictable and consistent outcomes for every restoration.

Achieving Material-Specific Properties

Modern dental ceramics are highly specialized. A cycle designed for a simple porcelain build-up is completely different from one required for glazing or for the crystallization of a lithium disilicate crown. Programmable furnaces come with pre-set, manufacturer-validated programs for hundreds of materials.

Enhancing Workflow Efficiency

Technicians can select a pre-set program or a custom one saved to the machine (often via USB) in seconds. This eliminates manual data entry, reduces the chance of error, and allows technicians to monitor the process in real-time while focusing on other tasks.

Understanding the Trade-offs and Considerations

While powerful, programmable technology is not a magic bullet. True expertise requires understanding its limitations.

The "Black Box" Problem

Relying exclusively on pre-set programs without understanding the underlying principles can be a pitfall. When a firing fails, a technician who only knows how to press "start" will struggle to diagnose whether the problem was the program, the material, or their own application technique.

Calibration is Non-Negotiable

A furnace's digital precision is only as good as its physical calibration. Furnaces must be regularly calibrated to ensure the programmed temperature matches the actual temperature inside the chamber. An uncalibrated machine promising +/-1°C accuracy is providing a false sense of security.

Garbage In, Garbage Out

A perfect firing program cannot fix a poorly fabricated restoration. If the porcelain layering is inadequate, the margins are poor, or the wrong material was selected, the most advanced furnace in the world will still produce a failed result.

How to Apply This to Your Lab

Use the furnace's programmability as a tool to achieve specific goals, not as a crutch.

- If your primary focus is high-volume consistency: Standardize your workflow around manufacturer-validated pre-set programs and use USB drives to ensure every furnace in the lab is running the identical, proven cycle.

- If your primary focus is advanced custom esthetics: Start with a base program and learn to make small, incremental adjustments to the hold time or peak temperature to achieve unique effects in translucency or shade.

- If your primary focus is introducing a new ceramic material: Always begin with the exact firing cycle recommended by the material's manufacturer, as this is the baseline for achieving its warrantied physical properties.

Mastering programmable firing cycles transforms the furnace from a simple oven into a precision instrument for creating predictable, high-quality dental art.

Summary Table:

| Parameter | Function | Impact on Restoration |

|---|---|---|

| Temperature Ramp Rate | Controls heating speed | Prevents thermal shock and cracks |

| Target Temperature | Reaches sintering point | Ensures strength and material fusion |

| Hold Time | Maintains peak temperature | Achieves uniform translucency and maturity |

| Cooling Rate | Manages temperature decrease | Prevents internal stresses and fractures |

Ready to elevate your dental lab's precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need reliable programmable porcelain furnaces or tailored solutions for consistent ceramic firing, we're here to help. Contact us today to discuss how our expertise can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures