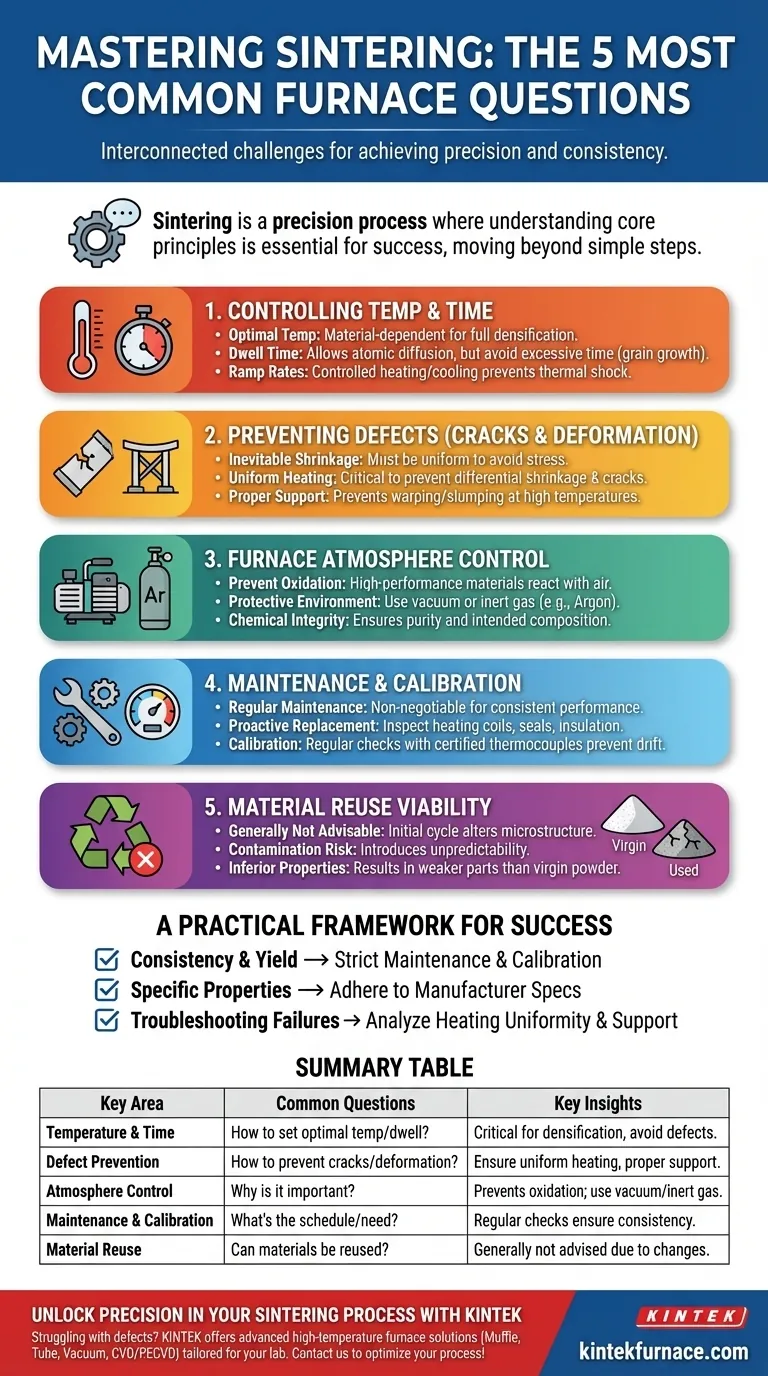

The most common questions about sintering furnaces revolve around five key areas: setting the optimal temperature and time, preventing part cracking or deformation, controlling the furnace atmosphere, establishing a maintenance schedule, and the viability of reusing sintered materials. These questions arise because sintering is a precision process where small deviations can lead to complete failure, making a deep understanding of the core principles essential for success.

The frequent questions about sintering are not isolated queries; they are interconnected parts of a single, fundamental challenge. Mastering the sintering process means moving beyond simple operational steps to understand how temperature, time, and atmosphere collectively influence the final material structure and integrity.

Controlling the Core Variables: Temperature and Time

The most fundamental parameters in any sintering cycle are temperature and time. They are the primary drivers of the physical transformation that turns a compacted powder into a dense, solid part.

Why Sintering Temperature is Critical

Sintering works by heating a material to a temperature just below its melting point. This high thermal energy excites the atoms, allowing them to diffuse across the boundaries of individual powder particles and bond them together.

The optimal temperature is entirely material-dependent. A temperature suitable for one ceramic, like zirconia, might be completely wrong for a powder metal or another type of ceramic, leading to either incomplete densification or melting.

The Role of Sintering Time (Dwell Time)

Time, specifically the "dwell time" spent at the peak sintering temperature, allows the atomic diffusion process to progress. Insufficient time results in a porous, weak part because the atomic bonds have not fully formed.

However, excessive time can be just as detrimental. It can lead to unwanted grain growth within the material's microstructure, which often degrades mechanical properties like strength and hardness.

The Relationship Between Heating/Cooling Rates

The rate at which the furnace ramps up to and cools down from the peak temperature is also a critical variable. Ramping too quickly can introduce thermal shock and internal stresses, which are a primary cause of defects.

Preventing Sintering Defects: Cracks and Deformation

Successfully sintering a part means more than just making it solid; it means achieving the desired final shape without any structural flaws.

The Root Cause: Inevitable Shrinkage

During sintering, as powder particles fuse and pores are eliminated, the overall part shrinks. This is a natural and expected part of the process, with materials like zirconia undergoing significant, predictable shrinkage.

The challenge is not the shrinkage itself, but ensuring that it occurs uniformly throughout the entire part.

How Non-Uniform Heating Causes Stress

If one section of a part heats or cools faster than another, it will shrink at a different rate. This differential shrinkage creates immense internal stress. When that stress exceeds the material's strength at that elevated temperature, it relieves itself by forming a crack.

The Importance of Proper Support

At sintering temperatures, materials lose a significant amount of their rigidity. Without proper support structures, a part can slump, warp, or deform under its own weight, ruining its dimensional accuracy.

The Critical Role of Furnace Atmosphere

The environment inside the furnace is just as important as the temperature. At such high heat, materials are extremely reactive, and uncontrolled atmospheric conditions can ruin the product.

Preventing Oxidation and Contamination

Most high-performance materials will readily oxidize if heated in the presence of air. This oxidation can alter the material's chemical composition and severely degrade its properties.

To prevent this, sintering is often performed in a high-vacuum condition or under a protective atmosphere of inert gas, such as argon. This ensures the material only reacts with itself, not its environment.

Ensuring Chemical Integrity

The goal of atmosphere control is to maintain the chemical purity and intended composition of the material. A controlled atmosphere, whether vacuum or inert gas, produces a highly compacted, pure output product with the desired final properties.

Understanding the Trade-offs and Best Practices

Operational excellence in sintering requires balancing speed and cost against quality and consistency. This is where maintenance and calibration become critical.

Performance vs. Longevity: The Maintenance Question

Regular maintenance is not an optional task; it is a requirement for consistent performance. Skipping it may save time in the short term, but it leads to process variability, failed batches, and eventual furnace failure.

Elements like heating coils, insulation, and vacuum seals degrade over time and must be inspected and replaced proactively.

Why Calibration is Non-Negotiable

A furnace's temperature controller reading can drift over time. A furnace set to 1500°C might actually be running at 1480°C or 1520°C. This deviation is often enough to ruin a batch.

Regular calibration, using a certified thermocouple, ensures that the setpoint temperature is the true temperature inside the chamber, which is the cornerstone of a repeatable process.

The Question of Material Reuse

While recycling is a common question, reusing previously sintered material is generally not advisable for high-performance applications. The initial sintering cycle fundamentally alters the material's microstructure and can introduce contamination.

Attempting to re-sinter this material will lead to unpredictable results and is likely to produce a part with inferior properties compared to one made from virgin powder.

A Practical Framework for Sintering Success

To move from asking common questions to achieving consistent results, focus your efforts based on your primary objective.

- If your primary focus is consistency and high yield: Prioritize a strict maintenance and calibration schedule and implement controlled, conservative heating and cooling rates.

- If your primary focus is achieving specific material properties: Adhere precisely to the material manufacturer's specifications for temperature, dwell time, and required atmosphere.

- If your primary focus is troubleshooting failures like cracks: Scrutinize the uniformity of your heating/cooling cycles and analyze the adequacy of the part's support structure within the furnace.

Ultimately, mastering sintering comes from treating the furnace not as a simple oven, but as a precision instrument.

Summary Table:

| Key Area | Common Questions | Key Insights |

|---|---|---|

| Temperature & Time | How to set optimal temperature and dwell time? | Material-dependent; critical for densification and avoiding defects. |

| Defect Prevention | How to prevent cracks and deformation? | Ensure uniform heating and proper part support to manage shrinkage. |

| Atmosphere Control | Why is furnace atmosphere important? | Prevents oxidation; use vacuum or inert gases for purity. |

| Maintenance & Calibration | What's the maintenance schedule and calibration need? | Regular checks ensure consistency and prevent process variability. |

| Material Reuse | Can sintered materials be reused? | Generally not advisable due to microstructural changes and contamination. |

Unlock Precision in Your Sintering Process with KINTEK

Struggling with sintering defects or inconsistent results? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Whether you're focused on consistency, specific material properties, or troubleshooting, we deliver reliable, high-performance equipment to enhance your outcomes.

Contact us today to discuss how our sintering furnaces can optimize your process and drive success!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing