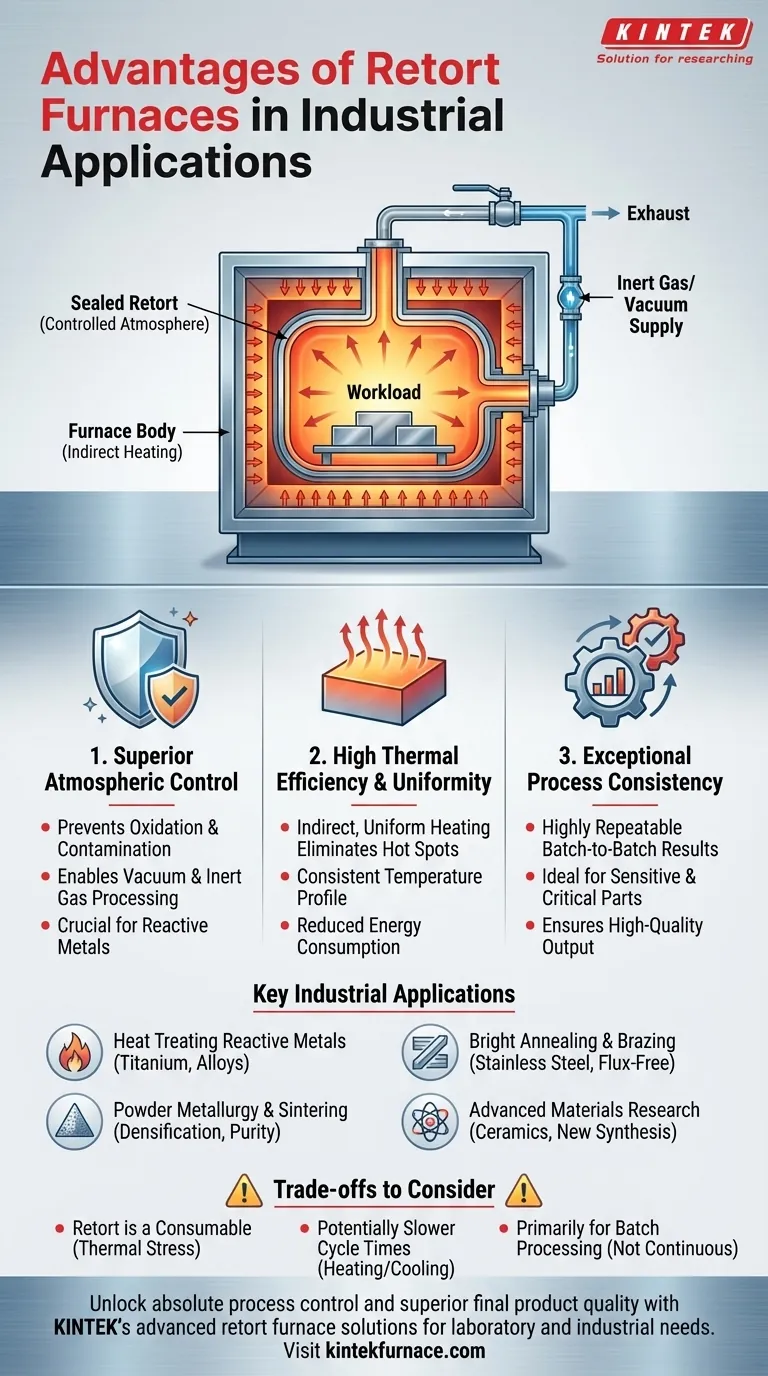

In short, retort furnaces offer significant advantages in industrial applications by providing superior atmospheric control, high thermal efficiency, and exceptional process consistency. These benefits stem from a unique design that isolates the material being processed from the heating elements and the external environment, leading to higher quality products and more efficient operation.

The core value of a retort furnace lies in its ability to create a pristine, highly controlled micro-environment. By physically separating the workload within a sealed chamber (the retort), it eliminates contamination and ensures precise, uniform heating, which is critical for sensitive materials and high-specification processes.

The Core Principle: A Controlled Atmosphere

A retort furnace's primary advantage is its ability to meticulously control the atmosphere surrounding the workpiece. This is the foundation for almost all its other benefits.

What is a Retort?

A retort, sometimes called a muffle, is a sealed container typically made of high-temperature metal alloys or ceramic. This chamber holds the materials being heat-treated and is placed inside the main furnace body. The furnace heats the outside of the retort, and the heat radiates inward to the workload.

Preventing Oxidation and Contamination

By sealing the workload inside the retort, you prevent it from coming into contact with air or the combustion byproducts from fuel-fired heating elements. This allows for processing in a vacuum or a specific, controlled atmosphere (e.g., nitrogen, argon, hydrogen). This capability is essential for preventing oxidation, discoloration, and decarburization.

Ensuring Process Purity

This isolation is critical in industries like electronics and advanced ceramics, where even trace amounts of contamination can ruin the material's electrical or structural properties. The retort acts as a physical barrier, ensuring the process remains pure from start to finish.

Achieving Superior Efficiency and Uniformity

Beyond atmospheric control, the retort design directly contributes to better heating performance and repeatability.

Efficient and Uniform Heating

Heat is transferred from the furnace's heating elements to the retort walls, which then radiate that energy uniformly onto the entire workload. This indirect heating method eliminates hot spots and ensures every part of the material experiences the same temperature profile, which is vital for processes like sintering and annealing.

Improved Thermal Efficiency

While heating a separate chamber, modern retort furnaces are designed with efficient heating mechanisms and insulation. This often results in reduced fuel or electricity consumption compared to older or less-controlled furnace designs, making the process more cost-effective.

Consistent Process Results

The sealed, uniform environment means that results are highly repeatable from one batch to the next. For applications like furnace brazing or the heat treatment of critical aerospace parts, this level of consistency is not just a benefit—it's a requirement.

Key Industrial Applications

The unique advantages of retort furnaces make them indispensable across several demanding industries.

Heat Treating Reactive Metals

Materials like titanium and its alloys react aggressively with oxygen at high temperatures. Retort furnaces provide the inert atmosphere or vacuum necessary to process these parts without compromising their material properties.

Bright Annealing and Brazing

"Bright annealing" refers to softening stainless steel without causing the surface to oxidize, keeping it shiny and "bright." This eliminates the need for costly and time-consuming secondary cleaning steps like acid pickling. Similarly, brazing requires a clean, flux-free environment for the filler metal to properly join components.

Powder Metallurgy and Sintering

Sintering involves heating compacted powders to just below their melting point to fuse them into a solid object. Uniform temperature is critical for achieving proper densification and strength, while a controlled atmosphere prevents unwanted chemical reactions within the powdered material.

Advanced Materials and Research

Universities and research institutions rely on retort furnaces for synthesizing new materials, creating advanced ceramics, and conducting high-temperature experiments where precise control over every variable is paramount.

Understanding the Trade-offs

While powerful, retort furnaces are not the universal solution for all heating applications. Objectivity requires acknowledging their limitations.

The Retort is a Consumable

The retort itself is exposed to extreme thermal stress. Over time, it will degrade, warp, or crack, especially when used at very high temperatures. Retorts are expensive, and their replacement must be factored into the furnace's total cost of ownership.

Potentially Slower Cycle Times

Heating the thermal mass of the retort in addition to the workload can sometimes increase heat-up times. More significantly, the sealed and insulated nature of the design can make cooling cycles slower compared to open or continuous furnaces where products can be quenched directly.

Primarily for Batch Processing

Most retort furnaces are designed for processing materials in discrete batches. For very high-volume, continuous production of non-sensitive parts, a continuous belt or roller hearth furnace may be a more efficient and economical choice.

Making the Right Choice for Your Process

Selecting the right furnace technology requires aligning its capabilities with your primary process goals.

- If your primary focus is material purity and surface finish: A retort furnace is the definitive choice for preventing oxidation and contamination, especially for reactive metals and bright finishing.

- If your primary focus is process repeatability for sensitive parts: The exceptional temperature uniformity and atmospheric control of a retort furnace ensure consistent, high-quality results from batch to batch.

- If your primary focus is high-volume output of non-reactive materials: A continuous, direct-fired furnace may offer a more cost-effective and higher-throughput solution.

Ultimately, choosing a retort furnace is an investment in absolute process control and superior final product quality.

Summary Table:

| Advantage | Description |

|---|---|

| Atmospheric Control | Sealed retort prevents contamination, allows vacuum or inert gas use for oxidation-free processing. |

| Thermal Efficiency | Indirect heating reduces energy consumption, ensures uniform temperature distribution. |

| Process Consistency | Repeatable results for sensitive applications like brazing and annealing. |

| Material Purity | Ideal for reactive metals and advanced materials, maintaining surface finish and properties. |

Unlock the full potential of your industrial processes with KINTEK's advanced retort furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in heat treating, powder metallurgy, or materials research, KINTEK ensures superior atmospheric control, efficiency, and consistency. Contact us today to discuss how our solutions can enhance your product quality and operational efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation