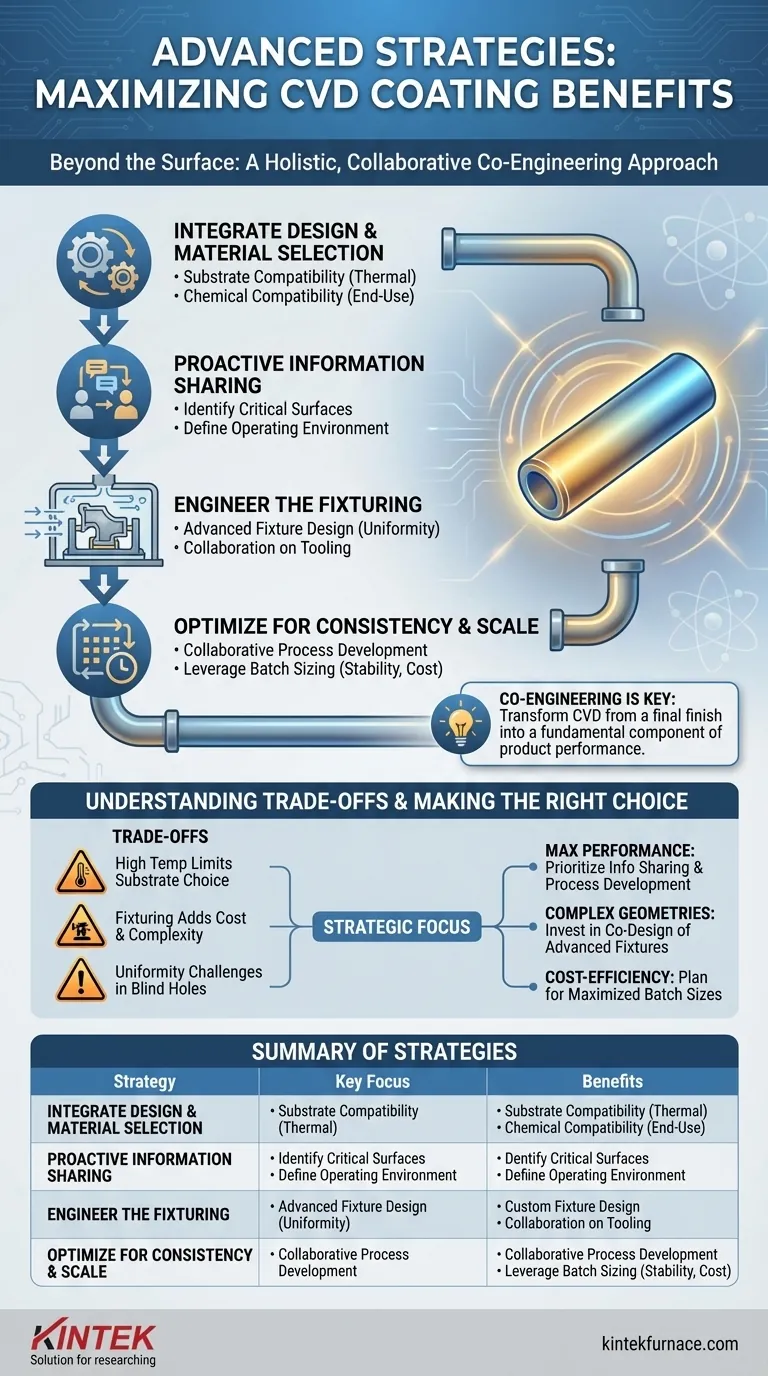

To truly maximize the benefits of Chemical Vapor Deposition (CVD), you must look beyond the coating itself and treat the entire process as an integrated engineering system. Advanced strategies involve a proactive partnership between the product designer and the coating specialist, focusing on collaborative design, precise material selection, and optimized processing long before the first part is coated. This approach transforms the coating from a final finish into a fundamental component of the product's performance.

The most significant gains in CVD performance do not come from simply choosing a better coating, but from co-engineering the part, the fixture, and the process itself. Success is determined by the quality of collaboration and the depth of shared information between you and your coating partner.

The Foundation: Why CVD Demands a Deeper Strategy

Chemical Vapor Deposition is not a simple paint or plating. It is a process that builds a new material, atom by atom, onto a substrate's surface, creating an exceptionally strong bond and a highly uniform layer.

The Principle of Precision and Uniformity

CVD precursors are gases that flow around the part, allowing the coating to form uniformly on every exposed surface. This includes complex shapes, internal channels, and seal areas that are impossible to cover with line-of-sight processes like PVD (Physical Vapor Deposition). This unique characteristic is the basis for its high-performance applications.

Tailoring Properties at the Molecular Level

The process allows for immense customization. By adjusting the precursor gases, temperature, and pressure, the resulting coating's properties can be finely tuned. You can optimize for extreme wear resistance, chemical inertness, lubricity, corrosion resistance, or high purity, depending on the specific demands of the application.

Advanced Strategies for Peak Performance

To leverage these foundational strengths, you must move from a transactional mindset to a collaborative one. The following strategies are essential for achieving superior results.

Strategy 1: Integrate Design and Material Selection

The process begins with the part's initial design. The substrate material is not just a carrier for the coating; it is part of the final composite system.

- Substrate Compatibility: CVD processes often involve high temperatures. You must ensure your chosen base material (metal, ceramic, glass) can withstand the thermal cycle without warping, annealing, or compromising its structural integrity.

- Chemical Compatibility: The coating must be chemically stable for your end-use application. Clearly define the chemical environment the part will experience to select a coating that will not degrade or react.

Strategy 2: Proactive Information Sharing

Your coating provider cannot optimize what they do not know. Providing detailed application information is the single most critical step you can take.

- Identify Critical Surfaces: Clearly mark drawings to indicate which surfaces are functionally critical and which are non-critical. This guides fixturing and quality control.

- Define the Operating Environment: Share everything about the part's life. This includes operating temperatures (and thermal cycling), mechanical stresses, contact pressures, and exposure to corrosive agents.

Strategy 3: Engineer the Fixturing

How a part is held within the CVD reactor is not a trivial detail; it is a critical process variable that directly controls coating quality and uniformity.

- Advanced Fixture Design: For complex parts, custom fixtures are essential. The goal is to position each part to ensure uniform gas flow across all critical surfaces, preventing gas shadows or pooling that can cause inconsistencies in thickness.

- Collaboration on Fixtures: Work with your coating expert to develop this tooling. Their experience with gas dynamics inside the reactor is invaluable for designing fixtures that guarantee consistent results.

Strategy 4: Optimize for Consistency and Scale

Process stability is key to repeatable performance. Planning for production volume from the outset can yield significant benefits in both quality and cost.

- Collaborative Process Development: A true partnership involves jointly refining the coating process for your specific part. This may involve multiple test runs to dial in the perfect parameters.

- Leverage Batch Sizing: Larger, consistent batch sizes not only reduce per-unit costs but also improve process stability. Fewer startups and shutdowns lead to a more repeatable and reliable outcome for every part in the run.

Understanding the Trade-offs

No process is without limitations. Objectively understanding these trade-offs is key to making sound engineering decisions.

High Temperatures Can Limit Substrate Choice

The high heat required for many CVD processes can be a major constraint. It can alter the temper of certain steel alloys or damage temperature-sensitive components. This factor must be considered early in the material selection phase.

Fixturing Adds Complexity and Cost

While essential for quality, custom fixturing represents an upfront investment in both time and money. For low-volume or prototype runs, this cost can be significant and must be factored into the project budget.

Uniformity Is Not Automatic

Although CVD is known for non-line-of-sight coverage, extremely complex internal geometries or blind holes can still pose a challenge. Ensuring adequate gas flow and exhaust in these areas requires expert-level fixture design and process control.

Making the Right Choice for Your Goal

Your strategic focus will shift depending on your primary objective. Use these guidelines to prioritize your efforts.

- If your primary focus is maximum performance and reliability: Center your efforts on proactive information sharing and collaborative process development to create a perfectly tailored coating solution.

- If your primary focus is coating complex or internal geometries: Invest heavily in the co-design of advanced fixtures to guarantee uniform gas flow and complete coverage.

- If your primary focus is cost-efficiency at scale: Plan your production schedule to maximize batch sizes, as this enhances both process consistency and your bottom line.

By treating CVD as a holistic engineering discipline, you transform it from a simple surface treatment into a powerful tool for strategic advantage.

Summary Table:

| Strategy | Key Focus | Benefits |

|---|---|---|

| Integrate Design and Material Selection | Substrate and chemical compatibility | Ensures part integrity and optimal coating performance |

| Proactive Information Sharing | Detailed application data | Enables precise customization and prevents failures |

| Engineer the Fixturing | Uniform gas flow and coverage | Achieves consistent coating on complex geometries |

| Optimize for Consistency and Scale | Batch sizing and process stability | Reduces costs and improves repeatability |

Ready to elevate your lab's capabilities with tailored CVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for maximum performance and efficiency. Contact us today to discuss how we can partner for superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication