To achieve a truly seamless workflow, a dental furnace must be integrated into a complete digital ecosystem. The key additional components are intraoral or extraoral scanners for data capture, CAD/CAM software for design and manufacturing, and milling or grinding machines for producing the restoration. These elements work in concert to transform a digital impression into a finished, patient-ready product.

The core principle of a seamless workflow is not about any single piece of equipment, but about the uninterrupted digital chain connecting data acquisition (scanning), virtual design (software), and physical fabrication (milling), which culminates in the final heat treatment (furnace).

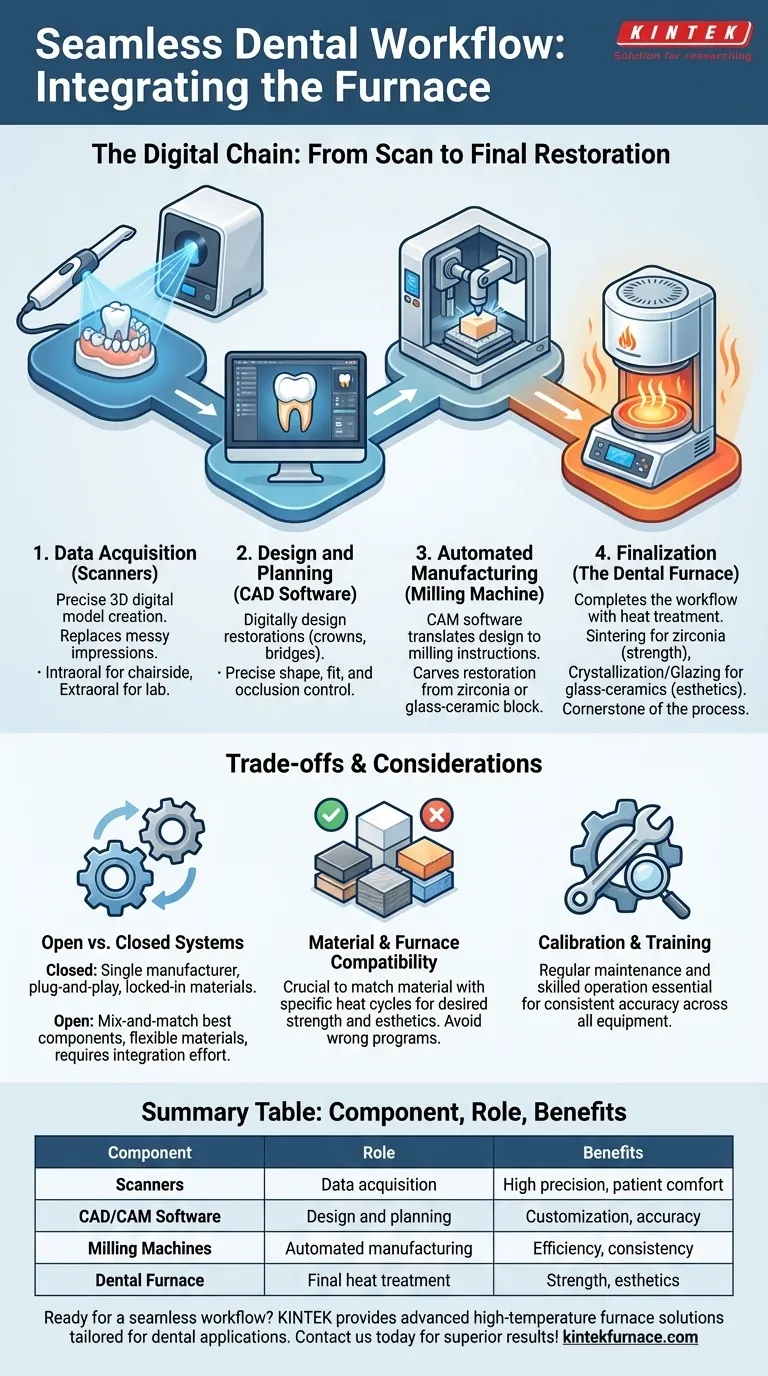

The Digital Workflow: From Scan to Final Restoration

Modern dentistry and dental lab technology rely on a Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) process. This digital workflow minimizes manual steps, increases precision, and dramatically improves efficiency. The furnace is the final, critical stage in this high-tech production line.

Step 1: Data Acquisition (The Scanners)

The entire process begins with creating a precise digital model of the patient's dentition. This replaces messy, uncomfortable traditional impression materials.

Two types of scanners accomplish this:

- Intraoral Scanners: These are small, wand-like devices used directly in the patient's mouth to capture a 3D image of the teeth and gums. This is the foundation of chairside, single-visit dentistry.

- Extraoral (Lab) Scanners: These are desktop units used in a dental laboratory to scan physical models or traditional impressions. They provide extremely high accuracy for complex cases.

Step 2: Design and Planning (The Software)

Once the 3D scan data is captured, it is imported into CAD (Computer-Aided Design) software.

Here, a dentist or technician digitally designs the restoration—be it a crown, bridge, or veneer. The software allows for precise control over shape, fit, and occlusion before any physical object is made.

Step 3: Automated Manufacturing (The Milling Machine)

The completed digital design is then sent to the CAM (Computer-Aided Manufacturing) software, which translates the design into a set of instructions for a milling machine.

The milling or grinding machine is a robotic device that automatically carves the restoration from a solid block of dental material, such as zirconia or glass-ceramic. The result is a precise but unfinished restoration, often in a chalky, pre-sintered state.

Step 4: Finalization (The Dental Furnace)

This is where the dental furnace completes the workflow. The milled restoration is placed into the furnace for a specific, pre-programmed heat cycle.

- For zirconia, this process is called sintering. It shrinks the restoration to its final size and hardens it, giving it immense strength.

- For glass-ceramics, the furnace performs crystallization and glazing, which provides the material with its final strength and tooth-like esthetics.

Without this final step, the high-tech restoration from the mill would be weak and unusable.

Understanding the Trade-offs and Considerations

A "seamless" workflow is powerful, but success depends on understanding the underlying system architecture and material science.

Open vs. Closed Systems

This is the most critical decision when building a digital workflow.

- Closed Systems: All components (scanner, software, mill, furnace) come from a single manufacturer. This offers true plug-and-play simplicity and unified support but locks you into one vendor's materials and technology.

- Open Systems: You can mix and match best-in-class components from different manufacturers. This provides maximum flexibility and access to a wider range of materials but may require more effort to ensure all parts communicate correctly.

Material and Furnace Compatibility

You cannot use just any furnace program with any material. Each dental ceramic has a unique, manufacturer-specified heating and cooling cycle required to achieve its prescribed physical and esthetic properties.

Using the wrong program can result in a fractured, weak, or improperly shaded restoration, wasting time and resources.

The Need for Calibration and Training

Digital does not mean fully automatic. To ensure consistent accuracy, every piece of equipment—the scanner, the mill, and the furnace—requires regular calibration and maintenance. Operator skill and training are paramount to managing the software and troubleshooting issues.

Making the Right Choice for Your Goal

Building a seamless digital workflow requires aligning your equipment choices with your specific operational needs.

- If your primary focus is a streamlined chairside (in-office) workflow: An integrated, closed system from a single brand is often the most efficient path to delivering single-visit restorations.

- If your primary focus is a high-volume dental lab: An open system provides the flexibility to combine specialized scanners, powerful software, and multiple mills to handle a diverse range of cases and materials from different clients.

- If your primary focus is a gradual, budget-conscious transition: Begin with an intraoral scanner and outsource the design and milling, allowing you to bring the full manufacturing process in-house with a mill and furnace later.

Ultimately, integrating these components correctly transforms the dental furnace from a standalone appliance into the cornerstone of a modern, efficient, and precise digital manufacturing process.

Summary Table:

| Component | Role in Workflow | Key Benefits |

|---|---|---|

| Scanners | Data acquisition for digital impressions | High precision, patient comfort |

| CAD/CAM Software | Design and planning of restorations | Customization, accuracy |

| Milling Machines | Automated manufacturing of restorations | Efficiency, consistency |

| Dental Furnace | Final heat treatment (sintering, crystallization) | Strength, esthetics |

Ready to enhance your dental lab's efficiency with a seamless digital workflow? KINTEK provides advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored for dental applications. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs. Contact us today to discuss how our furnaces can integrate into your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision