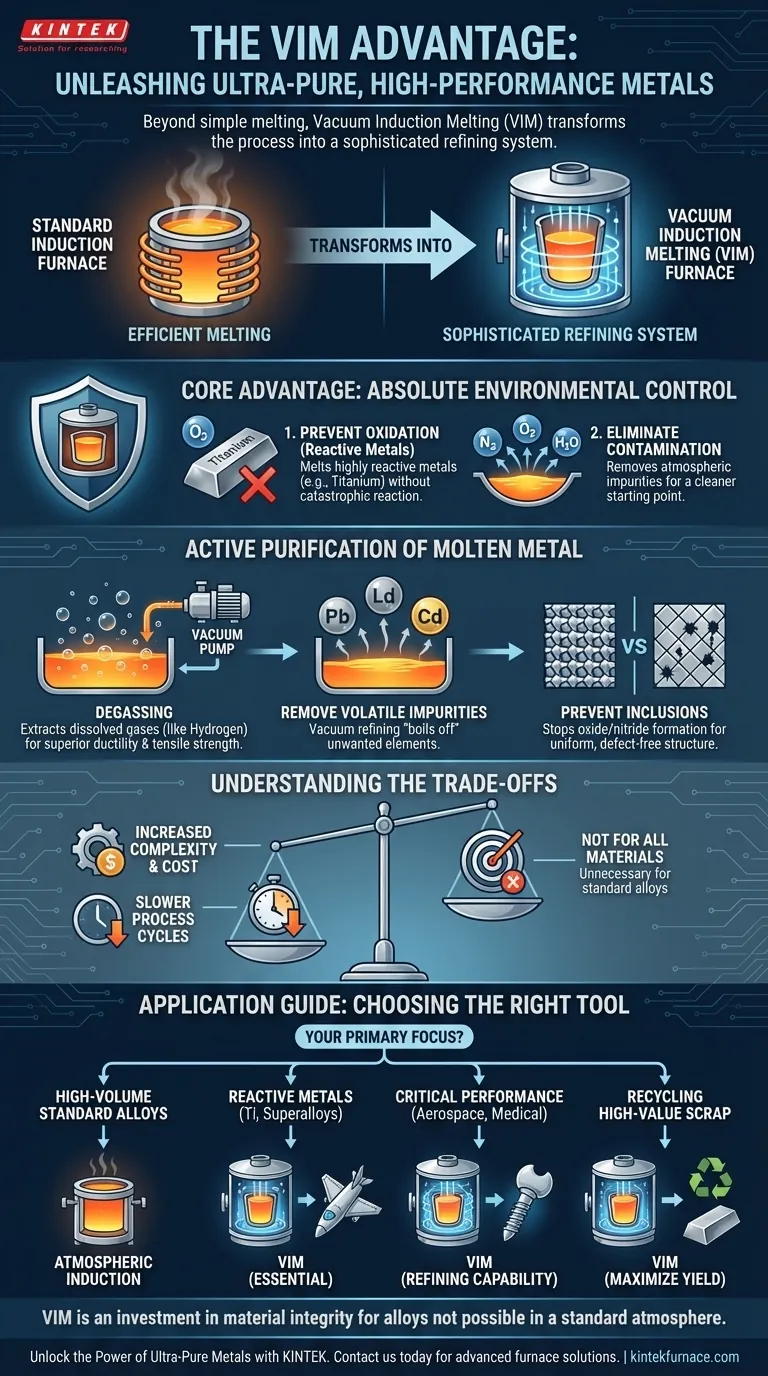

Beyond simple melting, a vacuum induction melting (VIM) furnace provides a fundamentally different level of metallurgical control. By performing the melting process inside a vacuum, it eliminates atmospheric contamination, actively removes impurities from the molten metal, and enables the processing of highly reactive materials that would be impossible to melt in an open-air environment.

While a standard induction furnace efficiently melts metal, adding a vacuum transforms it into a sophisticated refining system. This capability is not just an incremental improvement; it is the critical enabler for producing the ultra-pure, high-performance superalloys and reactive metals demanded by the aerospace, defense, and medical industries.

The Core Advantage: Absolute Environmental Control

The primary function of the vacuum is to create a pristine environment, removing the atmosphere as a variable in the metallurgical process.

Preventing Oxidation of Reactive Metals

Standard furnaces cannot melt highly reactive metals like titanium or certain superalloys. The moment they become molten, they react aggressively with oxygen and nitrogen in the air, leading to catastrophic contamination and useless material.

A VIM furnace removes the atmosphere, preventing oxidation and allowing these sensitive materials to be melted and cast while maintaining their required purity and properties.

Eliminating Atmospheric Contamination

Even for less reactive metals, the atmosphere introduces contaminants. Ambient air contains oxygen, nitrogen, and water vapor, which can dissolve into the molten metal, forming undesirable oxides and nitrides that compromise the final product.

The vacuum environment removes these contaminants before they can ever contact the melt, ensuring a cleaner starting point for the alloy.

Active Purification of the Molten Metal

A VIM furnace goes beyond simply preventing contamination; it actively cleanses the metal. The vacuum acts as a refining tool.

Degassing for Superior Mechanical Properties

Dissolved gases, particularly hydrogen, are a major source of defects. As the metal solidifies, this gas is forced out of solution, creating internal porosity that severely degrades mechanical properties like ductility and tensile strength.

The vacuum effectively pulls these dissolved gases out of the molten bath, resulting in a denser, more structurally sound final product with significantly improved performance.

Removing Volatile Impurities

The low-pressure environment lowers the boiling point of certain elements. This allows the furnace to "boil off" and remove unwanted volatile impurities like lead, cadmium, aluminum, and magnesium from the melt.

This process, known as vacuum refining, is crucial for producing metals with extremely high purity levels.

Preventing Non-Metallic Inclusions

Many defects in high-strength alloys are caused by non-metallic inclusions, such as oxides and nitrides. By removing oxygen and nitrogen from the environment, a VIM furnace prevents these inclusion-forming reactions from occurring in the first place.

This results in a cleaner metal with a more uniform internal structure, which is critical for applications where material failure is not an option.

Understanding the Trade-offs

While the benefits are significant, VIM technology is not a universal solution. The advantages come with clear trade-offs.

Increased Complexity and Cost

Vacuum pumps, chamber seals, and sophisticated controls make VIM furnaces significantly more expensive to purchase and maintain than their atmospheric counterparts. They require specialized knowledge to operate correctly.

Slower Process Cycles

Achieving and maintaining a deep vacuum takes time. The pump-down cycle adds a considerable amount of time to each melt, reducing overall throughput compared to a simple, open-air furnace.

Not Required for All Materials

For many common applications involving standard carbon steels or simple non-ferrous alloys, the level of purity offered by a VIM furnace is unnecessary. An atmospheric furnace is often faster, cheaper, and perfectly adequate for the job.

How to Apply This to Your Project

The decision to use a vacuum induction furnace depends entirely on your material requirements and performance goals.

- If your primary focus is high-volume production of standard alloys: A traditional atmospheric induction furnace likely offers the best balance of speed and cost.

- If your primary focus is producing reactive metals like titanium or superalloys: A vacuum induction furnace is non-negotiable to prevent catastrophic oxidation and ensure purity.

- If your primary focus is achieving maximum material performance for critical applications (e.g., aerospace, medical): The refining capabilities of a VIM furnace are essential for removing the gases and impurities that compromise mechanical properties.

- If your primary focus is recycling high-value scrap and revert: A VIM furnace maximizes yield by virtually eliminating metal loss to oxidation, making the recovery of expensive alloys economically viable.

Ultimately, choosing a vacuum induction furnace is an investment in material integrity, enabling the creation of alloys that are simply not possible in a standard atmosphere.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation | Eliminates atmospheric contact to melt reactive metals like titanium without contamination. |

| Removes Contaminants | Vacuum environment strips oxygen, nitrogen, and water vapor for cleaner metal. |

| Degasses Molten Metal | Extracts dissolved gases like hydrogen to improve ductility and tensile strength. |

| Eliminates Volatile Impurities | Lowers boiling points to remove elements such as lead and cadmium via vacuum refining. |

| Prevents Non-Metallic Inclusions | Stops oxide and nitride formation for uniform internal structure in high-strength alloys. |

Unlock the Power of Ultra-Pure Metals with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, defense, or medical sectors, our vacuum induction melting furnaces deliver the precision and purity you need for critical applications. Contact us today to discuss how we can enhance your metallurgical processes and achieve superior material performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace and Arc Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance