Absolutely. The High Vacuum Melting Furnace is not merely suitable for research applications; it is a foundational tool in modern materials science and metallurgy. Its primary value lies in its ability to create an ultra-clean and highly controllable environment, which is essential for developing and studying high-performance materials where purity and precise composition are non-negotiable.

The core strength of a vacuum melting furnace in a research setting is its power to isolate variables. By eliminating atmospheric contamination and controlling pressure, it allows researchers to study the intrinsic properties of a material and develop new alloys with unparalleled precision.

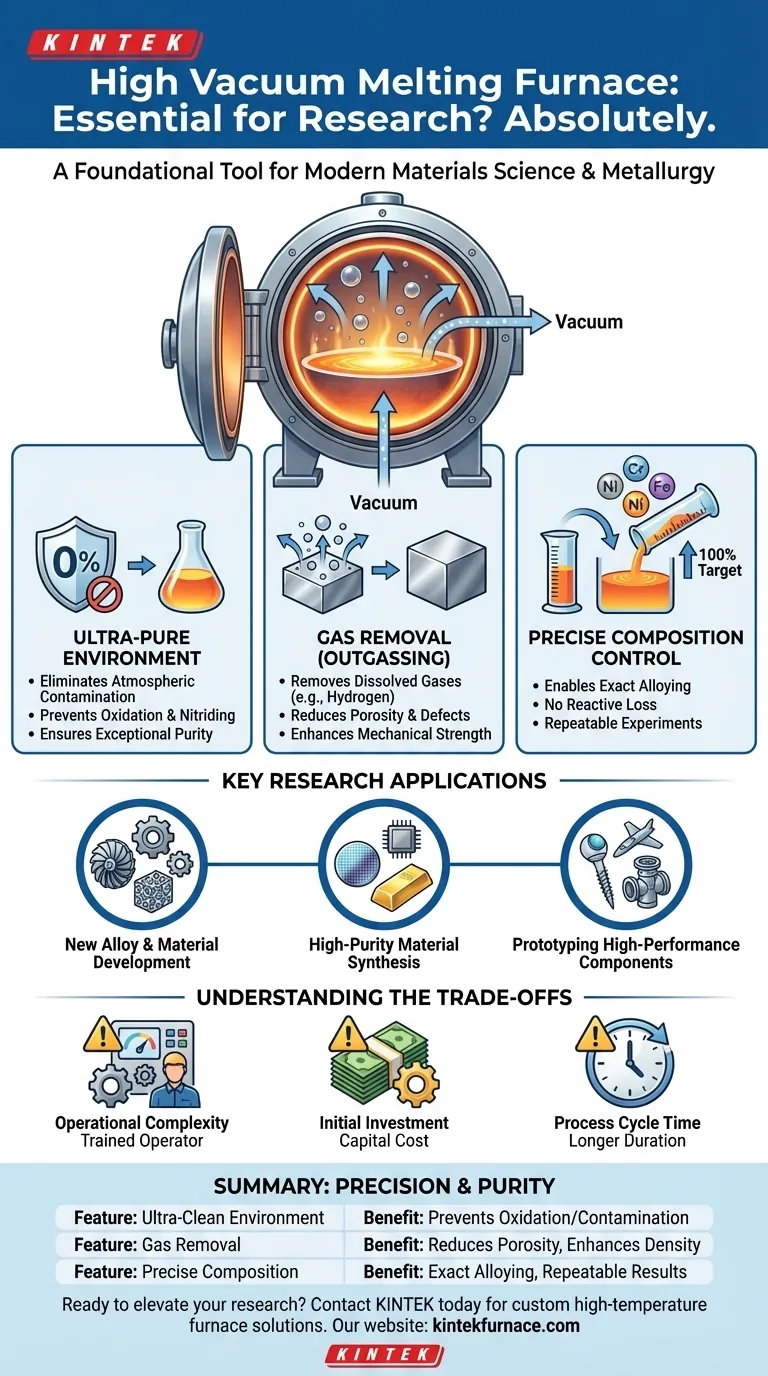

The Core Principle: Achieving an Ultra-Pure Environment

The defining characteristic of this furnace is its vacuum chamber. This feature is not just an add-on; it is the central reason for its utility in research and development.

Eliminating Atmospheric Contamination

In a standard furnace, molten metal is exposed to air, which is roughly 78% nitrogen and 21% oxygen. These reactive gases can readily dissolve into the metal, forming undesirable oxides and nitrides that compromise the material's final properties.

A high vacuum environment removes these reactive gases. This prevents oxidation and ensures the final product is exceptionally pure and free from atmospheric impurities.

Removing Dissolved Gases

Many metals contain dissolved gases like hydrogen from previous processing steps. These gases can cause porosity and internal defects when the metal solidifies, severely degrading its mechanical strength and integrity.

The vacuum actively pulls these dissolved gases out of the molten metal, a process known as outgassing. This results in a denser, more structurally sound material.

Enabling Precise Compositional Control

When developing a new alloy, the exact percentage of each element is critical. In a vacuum, researchers can introduce precise amounts of alloying elements without the risk of them reacting with the atmosphere.

This guarantees that the final composition of the material is exactly what was intended, allowing for repeatable experiments and the creation of alloys with very close compositional tolerances.

Key Research Applications

The furnace's ability to produce ultra-clean, precisely defined materials makes it indispensable across numerous fields of advanced research.

New Alloy and Material Development

Researchers use vacuum furnaces to create novel materials from the ground up. This includes high-temperature superalloys for jet engines, special steels for demanding industrial use, and amorphous metals (metallic glasses).

The controlled environment is also vital for synthesizing sensitive materials like superconductors and advanced ceramics, where even trace impurities can ruin the desired properties.

High-Purity Material Synthesis

Industries like electronics and semiconductors rely on materials of the highest possible purity. Vacuum melting is a key step in refining metals to produce the high-purity silicon, germanium, and other materials required for manufacturing microchips.

It is also used in refining precious metals and creating the master alloys used in jewelry and minting.

Prototyping High-Performance Components

For applied research in aerospace, biomedical, and energy, the furnace is used to cast prototype parts. The combination of purity and low porosity is critical for components that must withstand extreme stress, temperature, or corrosive environments.

Examples include casting turbine blades, medical implants, and complex valves for the energy sector.

Understanding the Trade-offs

While incredibly powerful, this technology is a specialized tool with specific considerations. An objective assessment requires acknowledging its operational demands.

Operational Complexity

A high vacuum furnace is not a simple "plug-and-play" device. It requires trained operators who understand vacuum technology, metallurgy, and the specific safety protocols involved. Proper maintenance of vacuum pumps and seals is essential for reliable operation.

Initial Investment

The precision engineering, vacuum systems, and control electronics make these furnaces a significant capital investment. The cost must be weighed against the specific research needs and the value of the data and materials it can produce.

Process Cycle Time

Achieving a high vacuum takes time. The full process cycle—including loading, pumping down to the target vacuum level, melting, casting, and cooling—can be longer than for a simple atmospheric furnace. This can impact throughput for labs with high sample volumes.

Making the Right Choice for Your Research

Your decision to use a High Vacuum Melting Furnace should be driven by the specific goals of your project.

- If your primary focus is fundamental materials science: The furnace's ability to eliminate variables and produce ultra-pure materials is absolutely essential for discovering intrinsic properties.

- If your primary focus is developing novel, high-performance alloys: The precise compositional control and protection from oxidation are the most critical features for your work.

- If your primary focus is process optimization or component prototyping: The ability to create dense, gas-free castings that mimic industrial-scale results makes this an invaluable tool for applied R&D.

Ultimately, the High Vacuum Melting Furnace empowers researchers to move beyond the limitations of conventional melting and explore the true potential of materials.

Summary Table:

| Feature | Benefit for Research |

|---|---|

| Ultra-Clean Environment | Prevents oxidation and contamination for pure material synthesis |

| Gas Removal (Outgassing) | Reduces porosity, enhancing material density and strength |

| Precise Composition Control | Allows exact alloying for repeatable experiments and new material creation |

| Key Applications | Alloy development, high-purity material synthesis, prototyping |

| Considerations | Higher initial cost, operational complexity, longer cycle times |

Ready to elevate your research with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for materials science and metallurgy. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're developing new alloys, synthesizing high-purity materials, or prototyping high-performance components, our furnaces deliver the ultra-clean, controlled environments essential for breakthrough discoveries. Contact us today to discuss how we can support your research goals and provide a customized solution!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys