The right choice between a ceramic and a zirconia dental furnace is determined by the materials you work with and the final restorations you produce. A ceramic furnace is used for firing and glazing aesthetic materials like porcelain at lower temperatures, while a zirconia furnace is used for sintering high-strength zirconia from its pre-sintered state into a dense, durable final form at much higher temperatures. They perform fundamentally different thermal processes and are not interchangeable.

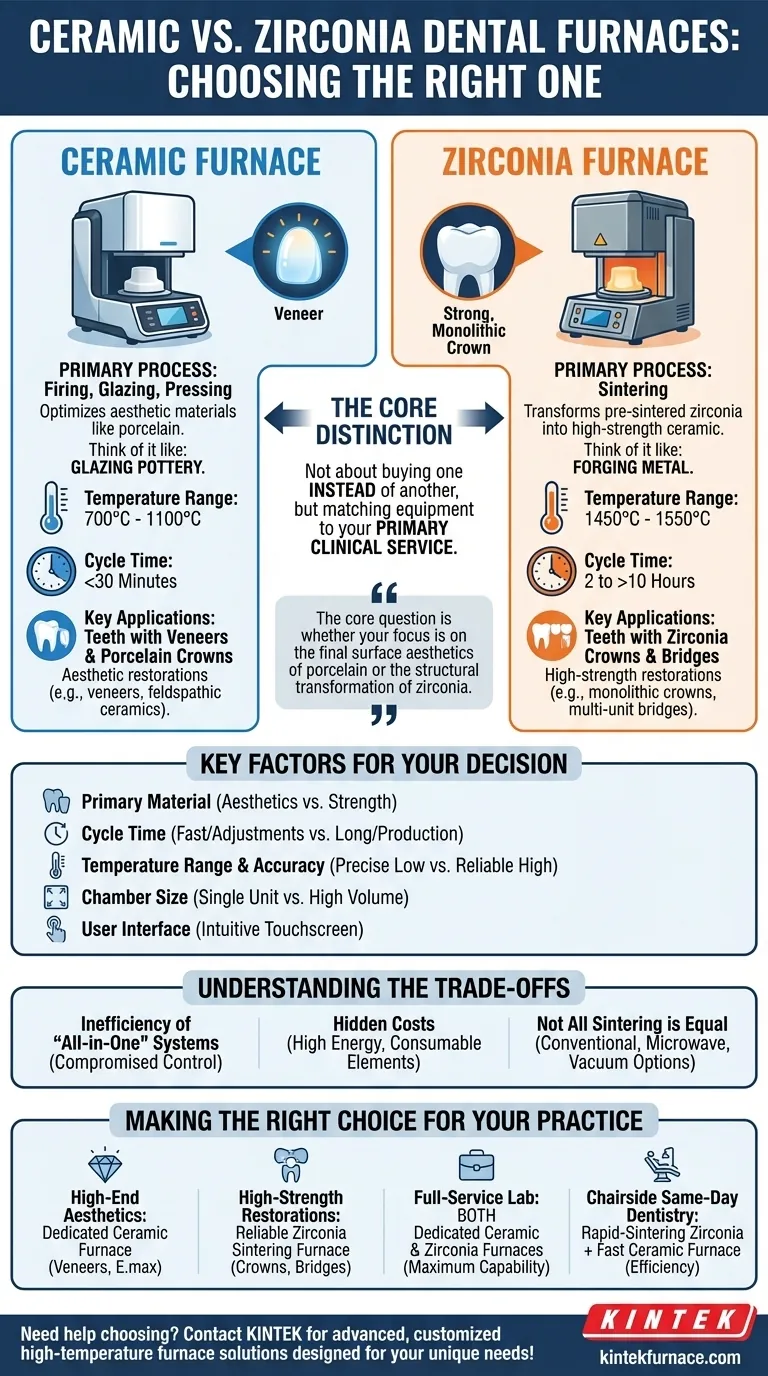

Your decision is not about buying one furnace instead of another; it's about matching your equipment to your primary clinical service. The core question is whether your focus is on the final surface aesthetics of porcelain or the structural transformation of zirconia.

The Core Distinction: Firing vs. Sintering

Understanding the difference between these two thermal processes is the key to making an informed decision. They are not simply "heating" a material; they are causing specific chemical and physical changes.

What is a Ceramic Furnace?

A ceramic furnace performs firing, glazing, and pressing of ceramic materials. This process typically occurs at temperatures between 700°C and 1100°C.

Think of it like glazing pottery. The goal is to fuse layers of porcelain, create a smooth, glass-like surface, and perfect the final shade and translucency of an aesthetic restoration like a veneer or feldspathic crown.

These furnaces are optimized for precision temperature control and often have shorter cycles, enabling quick turnaround for staining and glazing adjustments.

What is a Zirconia Furnace?

A zirconia furnace performs sintering. This process requires much higher temperatures, typically ranging from 1450°C to 1550°C, and much longer cycle times, often lasting several hours.

Sintering transforms a chalk-like, pre-sintered zirconia block into its final, high-strength ceramic state. During this process, the material shrinks significantly and becomes incredibly dense and durable.

Think of it like forging metal. You are fundamentally changing the material's structural properties to achieve maximum strength for monolithic crowns and multi-unit bridges.

Key Factors for Your Decision

Once you understand the primary function, you can evaluate specific features against your lab or practice's needs.

Primary Material & Restoration Type

This is the most important factor. If your work is 90% zirconia crowns and bridges, a sintering furnace is your priority. If you specialize in high-end anterior aesthetics using layered porcelain, a ceramic furnace is essential.

Cycle Time & Workflow Efficiency

Ceramic furnaces offer fast cycles, often under 30 minutes, which is ideal for chairside adjustments or quick glazing.

Zirconia furnaces require long cycles, from 2 to over 10 hours for conventional sintering. Newer "speed" sintering furnaces can drastically reduce this time but may have limitations on material compatibility.

Temperature Range & Accuracy

A zirconia furnace must be able to reliably reach and hold temperatures above 1500°C. A ceramic furnace requires exceptional accuracy at lower temperatures to avoid burning or discoloring delicate porcelains.

Chamber Size & Throughput

Consider how many units you need to process at once. A small chairside practice might only need to sinter a single crown, while a large production lab may need a furnace capable of holding 40 or more units in a single cycle.

User Interface & Program Control

Modern furnaces feature intuitive touchscreen interfaces with pre-set programs for various materials. This simplifies operation and ensures consistent, repeatable results, reducing the risk of user error.

Understanding the Trade-offs

Investing in this equipment requires you to be aware of the potential downsides and hidden complexities.

The Inefficiency of "All-in-One" Systems

Some furnaces claim to handle both ceramic firing and zirconia sintering. While versatile, these often represent a compromise. Using a high-temperature sintering furnace for low-temperature glazing can be energy-inefficient and may not offer the same precise control as a dedicated ceramic furnace.

The Hidden Costs: Energy and Elements

Zirconia sintering is an energy-intensive process due to the high temperatures and long cycles. Furthermore, the heating elements in these furnaces are consumables that will need periodic replacement, representing an ongoing operational cost.

Not All Sintering is Equal

Within zirconia furnaces, different technologies exist. Conventional furnaces are the workhorses but are slowest. Microwave sintering is faster and more energy-efficient but is a newer, more expensive technology. Vacuum furnaces can improve material quality but add complexity and cost.

Making the Right Choice for Your Practice

Evaluate your primary business goal to determine your equipment strategy.

- If your primary focus is high-end aesthetics (veneers, E.max): A dedicated, high-quality ceramic furnace for pressing and glazing is your essential tool.

- If your primary focus is high-strength restorations (zirconia crowns and bridges): A reliable zirconia sintering furnace is non-negotiable for your production workflow.

- If you run a full-service lab or want maximum in-house capability: You will almost certainly need both a dedicated ceramic furnace and a separate zirconia sintering furnace to work efficiently.

- If you are a chairside practice prioritizing same-day dentistry: A combination of a rapid-sintering furnace for zirconia and a small, fast ceramic furnace for characterization is the most efficient setup.

Ultimately, the right furnace is the one that directly enables the quality and efficiency of the specific dental restorations you provide.

Summary Table:

| Feature | Ceramic Furnace | Zirconia Furnace |

|---|---|---|

| Primary Process | Firing, glazing, pressing | Sintering |

| Temperature Range | 700°C - 1100°C | 1450°C - 1550°C |

| Typical Cycle Time | Under 30 minutes | 2 to over 10 hours |

| Key Applications | Aesthetic restorations (e.g., veneers, porcelain crowns) | High-strength restorations (e.g., zirconia crowns, bridges) |

| Material Focus | Porcelain, feldspathic ceramics | Pre-sintered zirconia blocks |

Struggling to choose the right dental furnace for your lab or practice? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to deliver precise temperature control and durability. Whether you're focused on aesthetic ceramics or high-strength zirconia, our deep customization capabilities ensure your furnace matches your clinical requirements perfectly. Contact us today to discuss how we can enhance your dental restoration workflow with reliable, efficient equipment!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations