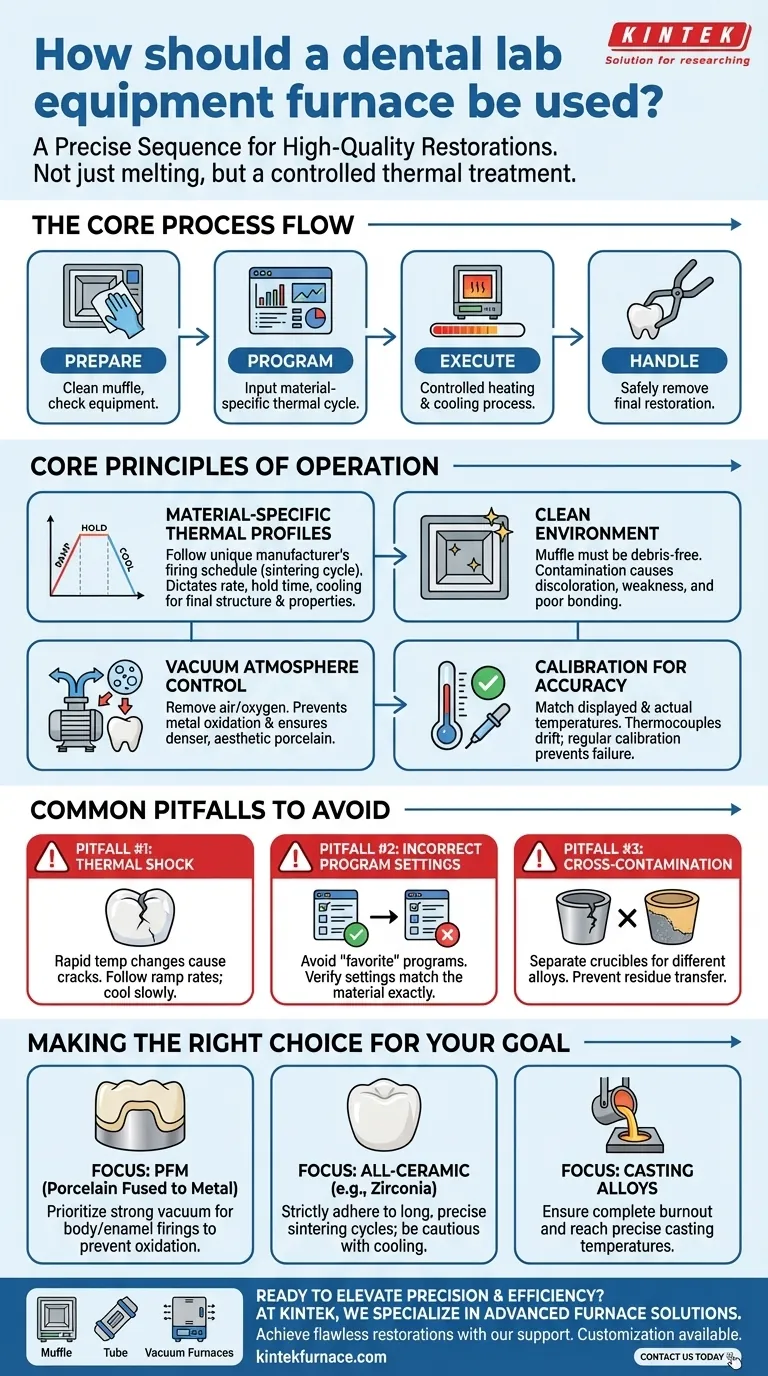

At its core, using a dental lab furnace involves a precise sequence of steps: preparing the furnace, accurately programming the required thermal cycle for the specific material, executing the heating and cooling process under controlled conditions, and safely handling the final restoration. This is not simply a melting process, but a highly controlled thermal treatment essential for achieving the desired physical and aesthetic properties of dental prosthetics.

The key to successful furnace operation is understanding that you are not just heating a material, but meticulously managing a thermal profile. Each stage—from temperature ramp-up to hold time and controlled cooling—is critical for ensuring the integrity, strength, and fit of the final dental crown, bridge, or implant.

The Core Principles of Furnace Operation

A dental furnace is more than an oven; it's a precision instrument. To use it effectively, you must master the principles that govern its function and impact the quality of your work.

Material-Specific Thermal Profiles

Every dental material, whether it's porcelain, zirconia, or a metal alloy, has a unique thermal recipe provided by its manufacturer. This "firing schedule" or "sintering cycle" dictates the exact rate of temperature increase, the specific temperatures to hold at, the duration of each hold, and the rate of cooling.

Deviating from this profile is a primary cause of failure. It dictates the material's final crystalline structure, which determines its strength, color, and translucency.

The Critical Role of a Clean Environment

Your furnace's muffle (the heating chamber) must be completely free of debris and contaminants before every cycle. Any foreign particles, from investment material dust to residual metal oxides from a previous firing, can become embedded in a restoration.

This contamination can cause discoloration, create points of weakness, or compromise the bond between porcelain and a metal substructure. Regular cleaning is a non-negotiable step for quality control.

Achieving Atmosphere Control with a Vacuum

Many modern dental furnaces use a vacuum pump. The purpose of pulling a vacuum during a ceramic firing cycle is to remove air from the chamber, which accomplishes two things.

First, it eliminates oxygen, preventing the oxidation of metal frameworks and ensuring a strong, clean bond with the porcelain. Second, it removes trapped air from within the porcelain particles, resulting in a denser, less porous, and more aesthetic final restoration.

Calibration for Temperature Accuracy

The temperature displayed on your furnace must match the actual temperature inside the muffle. Over time, thermocouples (the furnace's temperature sensors) can drift, leading to inaccurate readings.

Regularly calibrating your furnace using a certified calibration kit is essential. Firing even 10-15 degrees off the recommended temperature can ruin a sophisticated ceramic, leading to a weak, opaque, or glassy result.

Understanding the Common Pitfalls

Knowing what can go wrong is as important as knowing the correct procedure. Avoiding these common mistakes will save significant time, materials, and cost.

Pitfall #1: Thermal Shock

Thermal shock is the stress induced in a material by a rapid change in temperature. It is the leading cause of cracks in dental ceramics.

This occurs when a restoration is heated or cooled too quickly. Always follow the manufacturer's recommended temperature ramp rates and allow restorations to cool slowly, often by opening the furnace door in stages.

Pitfall #2: Incorrect Program Settings

Relying on a "favorite" program for all materials is a recipe for failure. Using a zirconia sintering cycle for a lithium disilicate (e.max) pressing, for example, would completely destroy the material.

Always verify that the program you select perfectly matches the material you are working with. Double-checking the parameters before pressing "start" is a crucial habit.

Pitfall #3: Cross-Contamination

If you use your furnace for both casting noble/precious alloys and non-precious alloys, you must have separate crucibles and take care to decontaminate the muffle. Trace elements from non-precious metals can contaminate a high-noble alloy, affecting its properties and biocompatibility.

The same principle applies to ceramics; never place a restoration directly on a surface that may have residue from a different type of material.

Making the Right Choice for Your Goal

Your specific workflow depends entirely on the material and the desired outcome. Adhere to the manufacturer's instructions for the material first, and use these principles as a guide.

- If your primary focus is Porcelain Fused to Metal (PFM): Prioritize a strong vacuum during the body and enamel firings to prevent oxidation and ensure a dense, vital-looking ceramic.

- If your primary focus is All-Ceramic Restorations (e.g., Zirconia): Adhere strictly to the long, precise sintering cycles and be extremely cautious about the cooling rate to prevent thermal shock and micro-cracks.

- If your primary focus is Casting Metal Alloys: Ensure the burnout oven has completely eliminated all wax from the investment mold before casting, and that you reach the precise casting temperature for the specific alloy to ensure a complete and accurate casting.

Mastering your dental furnace is the gateway to producing consistent, high-quality restorations that define the reputation of your lab.

Summary Table:

| Key Aspect | Description |

|---|---|

| Thermal Profiles | Follow material-specific schedules for temperature, hold times, and cooling rates. |

| Clean Environment | Keep the muffle free of debris to prevent contamination and discoloration. |

| Vacuum Control | Use vacuum to remove oxygen and air for oxidation prevention and denser restorations. |

| Calibration | Regularly calibrate temperature sensors for accuracy to avoid material failure. |

| Common Pitfalls | Avoid thermal shock, incorrect settings, and cross-contamination for better results. |

Ready to elevate your dental lab's precision and efficiency? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Our expertise in R&D and in-house manufacturing ensures you get reliable equipment like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique needs. Achieve flawless restorations with our support—contact us today to discuss how we can enhance your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations