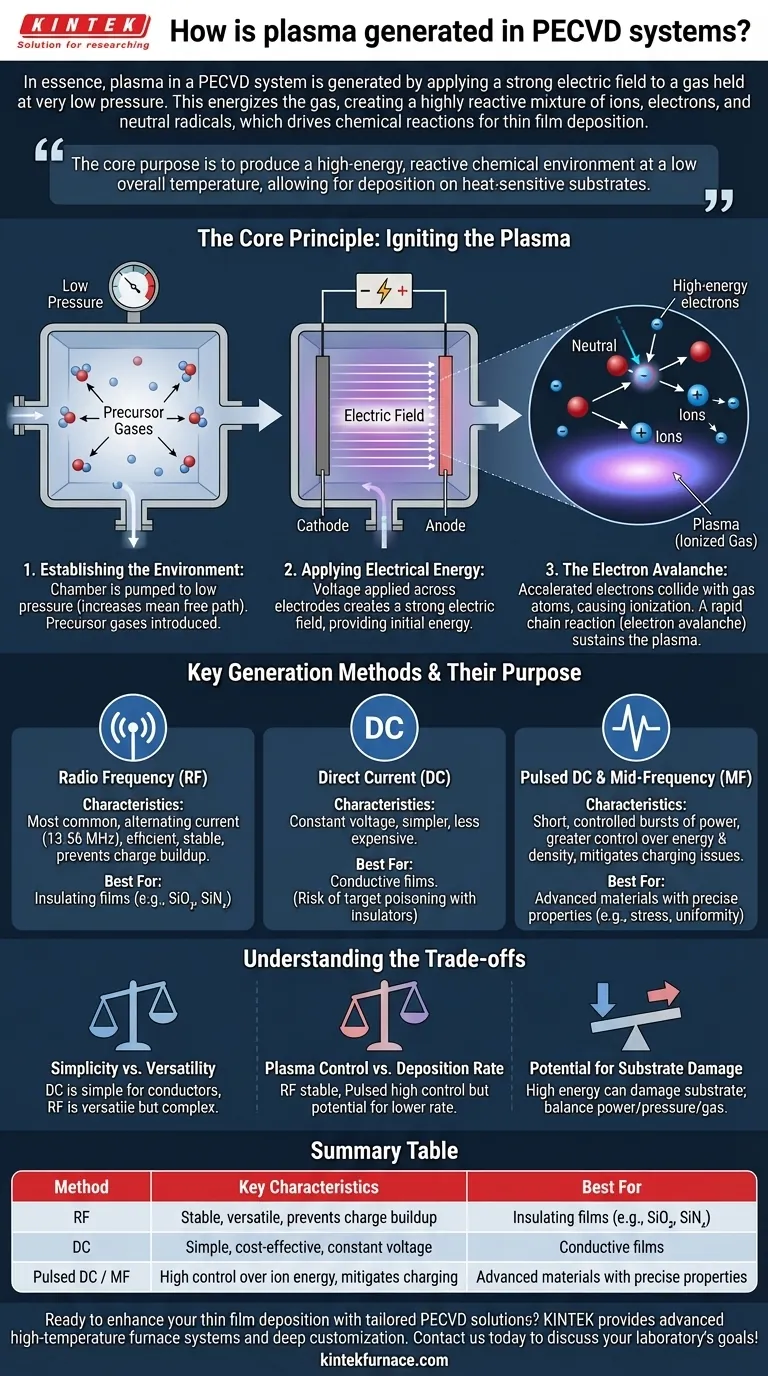

In essence, plasma in a PECVD system is generated by applying a strong electric field to a gas held at very low pressure. This process energizes the gas, stripping electrons from its atoms and molecules to create a highly reactive mixture of ions, electrons, and neutral radicals. This electrically charged gas, or plasma, is the engine that drives the chemical reactions for thin film deposition.

The core purpose of generating plasma in PECVD is not merely to create a glow discharge, but to produce a high-energy, reactive chemical environment at a low overall temperature. This allows for the deposition of high-quality thin films on substrates that could not withstand the heat of traditional thermal processes.

The Core Principle: Igniting the Plasma

Generating plasma follows a precise sequence of events. It transforms a stable, inert gas into a chemically active state capable of facilitating deposition.

Step 1: Establishing the Environment

First, a vacuum chamber is pumped down to a low pressure. This reduction in pressure is critical because it increases the "mean free path"—the average distance a particle can travel before colliding with another.

The chamber is then filled with a small amount of precursor gases. These are the source materials that will ultimately form the thin film.

Step 2: Applying Electrical Energy

Two electrodes within the chamber are connected to a power supply. When a voltage is applied, a strong electric field is created in the space between them.

This field acts as the accelerator, providing the initial energy required to start the plasma generation process.

Step 3: The Electron Avalanche

A few free electrons, naturally present in the gas, are accelerated to high speeds by the electric field. When one of these high-energy electrons collides with a neutral gas atom, it can knock another electron loose.

This process, known as ionization, creates a positive ion and another free electron. Now there are two electrons, which are then accelerated to cause more collisions. This creates a rapid chain reaction, or an electron avalanche, that quickly ionizes the gas and sustains the plasma.

Key Generation Methods and Their Purpose

The type of electrical power used has a significant impact on the plasma's characteristics and, consequently, the properties of the deposited film.

Radio Frequency (RF) Plasma

Radio Frequency (RF) is the most common method, typically using an alternating current at a standard industrial frequency of 13.56 MHz.

The rapid reversal of the electric field continuously accelerates electrons back and forth, leading to efficient and stable plasma generation. RF power is particularly effective for depositing insulating (dielectric) films, as it prevents charge from building up on surfaces.

Direct Current (DC) Plasma

Direct Current (DC) power supplies use a constant voltage. This is a simpler and often less expensive method for generating plasma.

However, DC plasma generation is primarily suited for depositing conductive films. If used with insulating materials, a phenomenon called "target poisoning" can occur, where an insulating layer builds up on the electrode and extinguishes the plasma.

Pulsed DC and Mid-Frequency (MF)

Pulsed DC and Mid-Frequency (MF) supplies are advanced alternatives that bridge the gap between DC and RF. They apply power in short, controlled bursts.

This pulsing action provides greater control over the plasma's energy and density. It helps mitigate the charging issues seen in standard DC while offering more precise regulation of film properties like stress and uniformity.

Understanding the Trade-offs

Choosing a plasma generation method is not about finding the "best" one, but the one best suited for a specific application. Each approach involves clear trade-offs.

Simplicity vs. Versatility

DC systems are the simplest to implement but are largely restricted to conductive materials. RF systems are far more versatile and can deposit virtually any material, but they require more complex and expensive impedance-matching networks to operate efficiently.

Plasma Control vs. Deposition Rate

While RF creates a stable, uniform plasma, methods like Pulsed DC offer an even higher degree of control over ion energy and flux. This precision can be critical for developing advanced materials but may sometimes come at the cost of a lower overall deposition rate.

Potential for Substrate Damage

The plasma is a high-energy environment. The same ion bombardment that activates the chemical reaction can also cause damage to the substrate or the growing film if not properly managed. The choice of power, pressure, and gas chemistry must be balanced to maximize deposition quality while minimizing damage.

Making the Right Choice for Your Goal

Your choice of plasma generation method should be dictated by the material you are depositing and the film properties you need to achieve.

- If your primary focus is process stability and depositing insulating films (like SiO₂ or SiNₓ): RF plasma is the industry standard and the most reliable choice.

- If your primary focus is a simple, cost-effective setup for depositing conductive films: A DC system is a perfectly viable and economical solution.

- If your primary focus is advanced control over film stress, density, and other mechanical properties: Pulsed DC or MF systems provide the precision needed for specialized applications.

Ultimately, understanding how plasma is formed is the first step toward controlling the PECVD process and engineering thin films with desired characteristics.

Summary Table:

| Plasma Generation Method | Key Characteristics | Best For |

|---|---|---|

| Radio Frequency (RF) | Stable, versatile, prevents charge buildup | Insulating films (e.g., SiO₂, SiNₓ) |

| Direct Current (DC) | Simple, cost-effective, constant voltage | Conductive films |

| Pulsed DC / Mid-Frequency (MF) | High control over ion energy, mitigates charging | Advanced materials with precise properties |

Ready to enhance your thin film deposition with tailored PECVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, boosting efficiency and results. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment