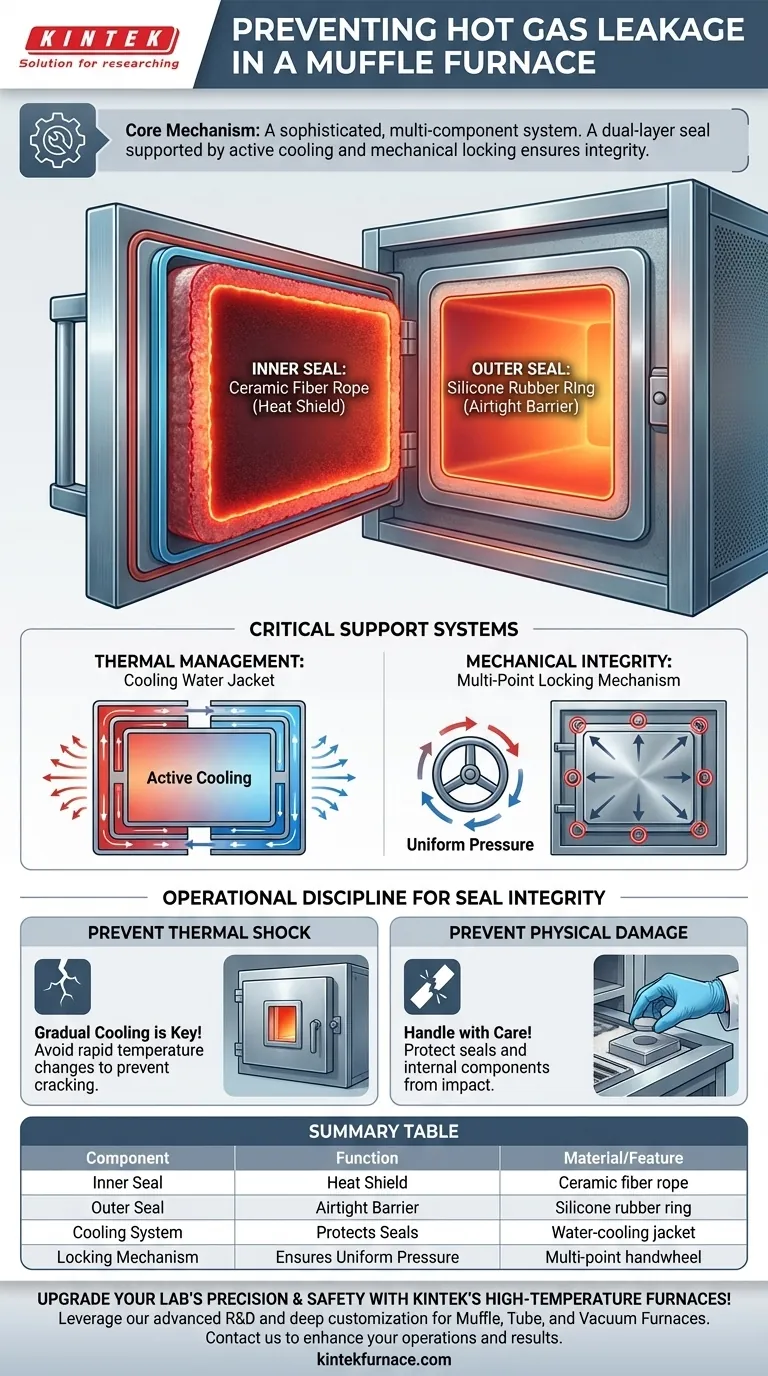

At its core, preventing hot gas leakage in a muffle furnace relies on a sophisticated, multi-component system at the furnace door. The primary mechanism is a dual-layer seal design, where an inner ceramic fiber rope withstands direct heat while an outer silicone rubber ring provides an airtight barrier. This system is supported by a water-cooling jacket and a multi-point locking mechanism to ensure its integrity and effectiveness.

The key to preventing leaks is not a single component, but an integrated system. Effective sealing depends on the synergy between heat-resistant materials, active cooling to protect sensitive parts, and a mechanical lock that applies uniform pressure.

The Anatomy of a Furnace Seal: A Two-Layer Defense

The furnace door is the most critical point of potential failure for containing hot gases. The design addresses this with two distinct layers, each serving a specific purpose.

The Inner Heat Shield: Ceramic Fiber Rope

The first line of defense, directly exposed to the furnace's extreme internal temperatures, is a ceramic fiber rope.

This material is chosen for its exceptional thermal resistance. Its primary job is not to be perfectly airtight, but to act as a robust thermal break, absorbing the brunt of the heat before it can reach the more sensitive outer seal.

The Outer Airtight Barrier: Silicone Rubber Ring

Behind the ceramic rope is an outer silicone rubber sealing ring. This is the component that creates the actual airtight seal.

Silicone is flexible and provides excellent sealing against gas flow, but it cannot withstand the high temperatures inside the furnace. It relies completely on the inner ceramic rope and the cooling system to keep its temperature within a safe operating range.

The Critical Support Systems

The two sealing materials cannot function alone. They are enabled by two crucial engineering systems: one for thermal management and one for mechanical pressure.

Thermal Management: The Cooling Water Jacket

To protect the silicone rubber seal from degrading or melting, a stainless steel cooling water jacket is installed at the furnace mouth.

This jacket circulates cool water, actively drawing heat away from the furnace door frame. This creates a temperature gradient, ensuring that while the furnace interior is at hundreds or thousands of degrees, the outer frame where the silicone ring sits remains cool enough for it to function effectively and have a long service life.

Mechanical Integrity: The Multi-Point Locking Mechanism

A seal is only effective if it is compressed evenly and firmly. This is achieved with a multi-point handwheel rotation locking mechanism.

Instead of a single latch, this system uses multiple locking points around the perimeter of the door. When the handwheel is turned, it applies uniform pressure across the entire sealing surface, compressing both the ceramic and silicone layers to eliminate any potential gaps where hot gas could escape.

Operational Discipline and Seal Integrity

The long-term effectiveness of the sealing system is not just dependent on its design, but also on how the furnace is operated. Improper use can quickly compromise the seal.

The Danger of Thermal Shock

After a heating cycle, the furnace and its components are extremely hot. Opening the door suddenly creates thermal shock—a rapid, uneven change in temperature.

This can cause the ceramic components or even the furnace chamber itself to crack. A cracked or warped furnace door will no longer sit flush, rendering the entire sealing system ineffective. The correct procedure is to open a small slit first to allow for gradual cooling before fully opening the door.

Preventing Physical Damage

Careless loading and unloading of samples can also damage critical components. For instance, striking the thermocouple can break it, but it also highlights the risk of damaging the furnace's internal lining or the ceramic fiber seal itself.

Any physical damage to the sealing surfaces on the door or the furnace body will create a path for gas to leak.

How to Ensure a Leak-Free Operation

Your operational priorities will determine which aspects of the sealing system require the most attention.

- If your primary focus is maximum furnace lifespan: Prioritize the integrity of the cooling system and always follow gradual cool-down procedures to prevent thermal shock.

- If your primary focus is consistent experimental results: Emphasize the importance of the multi-point lock; ensure it is fully and evenly engaged every time to maintain a stable internal atmosphere.

- If your primary focus is safety and reliability: Conduct regular visual inspections of both the inner ceramic rope and outer silicone ring for signs of wear, brittleness, or damage.

Ultimately, maintaining a perfect seal is a function of understanding how these integrated systems work together to protect the furnace and your results.

Summary Table:

| Component | Function | Material/Feature |

|---|---|---|

| Inner Seal | Acts as heat shield | Ceramic fiber rope |

| Outer Seal | Provides airtight barrier | Silicone rubber ring |

| Cooling System | Protects seals from heat | Water-cooling jacket |

| Locking Mechanism | Ensures uniform pressure | Multi-point handwheel |

Upgrade your lab's precision and safety with KINTEK's high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our reliable sealing systems can enhance your operations and deliver consistent results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?