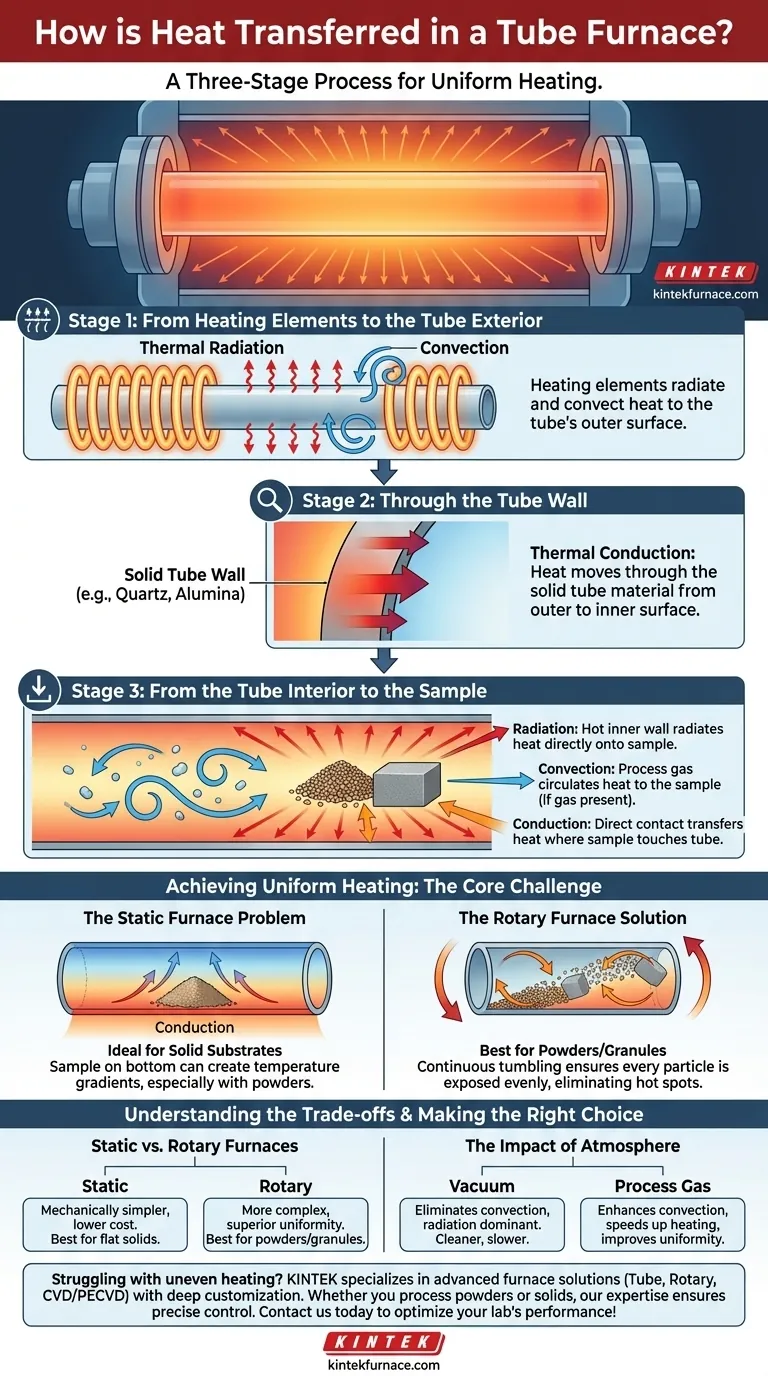

In short, heat is transferred to materials inside a tube furnace through a three-stage process. First, heating elements transfer energy to the outside of the furnace tube via radiation and convection. Next, this heat travels through the solid wall of the tube by conduction. Finally, the hot inner surface of the tube heats the sample inside through a combination of radiation, convection (if a gas is present), and direct conduction.

A tube furnace does not heat your sample directly. Instead, it creates a precisely controlled hot environment—the tube itself—which then transfers that heat to your material through a combination of all three fundamental heat transfer mechanisms. Understanding this sequence is key to achieving a uniform and predictable result.

The Three-Stage Heat Transfer Pathway

The journey of heat from the electrical outlet to your sample is a controlled chain of events. Each stage uses different physical principles to move the energy where it needs to go.

Stage 1: From Heating Elements to the Tube Exterior

The process begins with the heating elements, which are typically made of high-resistance materials like silicon carbide or molybdenum disilicide. When current flows through them, they get extremely hot.

These elements surround the process tube without touching it. The intense heat they generate is transferred to the outer surface of the tube primarily through two mechanisms:

- Thermal Radiation: The hot elements emit electromagnetic waves that are absorbed by the tube, raising its temperature. This is the dominant form of heat transfer at the high temperatures seen in most furnaces.

- Convection: The air or gas in the space between the elements and the tube heats up, circulates, and transfers heat to the tube's surface.

Stage 2: Through the Tube Wall

Once the exterior of the furnace tube is hot, the heat must travel to the interior. This transfer occurs purely through thermal conduction.

Heat energy moves directly through the solid material of the tube—whether it's quartz, alumina, or another ceramic—from the hotter outer surface to the cooler inner surface. The efficiency of this step depends on the thermal conductivity of the tube material.

Stage 3: From the Tube Interior to the Sample

This is the final and most nuanced stage, where heat is transferred from the hot inner wall of the tube to your material. All three heat transfer modes can be at play inside the tube.

- Radiation: The hot inner wall of the tube radiates heat directly onto the surface of your sample. For samples in a vacuum or at very high temperatures, this is often the primary mechanism.

- Convection: If you are using a process gas (like argon, nitrogen, or air), the gas heats up upon contact with the tube wall. It then circulates within the tube, transferring heat to your sample.

- Conduction: Where your sample physically touches the bottom or sides of the tube, heat is transferred through direct contact. This is most relevant for the parts of the sample resting on the tube floor.

Achieving Uniform Heating: The Core Challenge

Simply getting the sample hot is not enough; for most processes, it must be heated uniformly. Inconsistent heating can lead to failed experiments, with some parts of the sample being under-processed while others are overheated.

The Static Furnace Problem

In a standard, static tube furnace, a sample lying at the bottom of the tube can create a temperature gradient. The bottom of the sample gets hot via conduction, while the top is heated more slowly by radiation and convection. This can be a problem, especially for powders or granules.

The Rotary Furnace Solution

Rotary tube furnaces solve this problem with a simple, effective mechanical solution: they rotate the entire process tube.

This rotation continuously tumbles or "flips" the material inside. By constantly mixing the sample, every particle is repeatedly exposed to direct conduction from the hot tube wall, convection from the internal atmosphere, and radiation from all angles. This dynamic movement is highly effective at eliminating hot spots and ensuring exceptional temperature uniformity.

Understanding the Trade-offs

Choosing the right heating approach requires understanding the inherent compromises between different methods and conditions.

Static vs. Rotary Furnaces

A static furnace is mechanically simpler and ideal for processing solid, flat substrates where the surface facing the heat source is the primary area of interest.

A rotary furnace is more complex but is essential for powders, granules, or any particulate matter that requires every surface to be heated evenly. The added mechanical system increases cost and maintenance but provides superior uniformity for these materials.

The Impact of Atmosphere

The environment inside the tube dramatically affects heat transfer.

Operating under vacuum eliminates convection entirely, making radiation the dominant transfer mechanism from the tube wall to the sample. This can result in slower heating but provides an ultra-clean, non-reactive environment.

Flowing a process gas introduces and enhances convection. This can speed up heating and help improve temperature uniformity, especially in a static furnace, as the moving gas helps distribute heat more actively.

Making the Right Choice for Your Goal

Your material and your process goal will dictate the most effective heating strategy.

- If your primary focus is a solid substrate or wafer: A static tube furnace is typically sufficient, as radiation from the uniform tube wall will heat the exposed surface effectively.

- If your primary focus is powders or granular materials: A rotary furnace is the superior choice to prevent temperature gradients and ensure every particle is processed evenly.

- If your primary focus is atmosphere control: Be aware that using a vacuum removes convection, while using a flowing gas enhances it, directly changing the dynamics of how your sample is heated.

By understanding this heat transfer chain, you can better control your experimental outcomes and select the right equipment for your specific application.

Summary Table:

| Stage | Heat Transfer Mechanism | Key Details |

|---|---|---|

| 1: Elements to Tube Exterior | Radiation, Convection | Heating elements radiate heat; air/gas convection transfers energy to tube surface. |

| 2: Through Tube Wall | Conduction | Heat moves through solid tube material (e.g., quartz, alumina) from outer to inner surface. |

| 3: Tube Interior to Sample | Radiation, Convection, Conduction | Inner tube radiates heat; gas convection circulates; direct contact conduction occurs if sample touches tube. |

| Uniform Heating Solutions | Method | Application |

| Static Furnace | Radiation-dominated | Ideal for solid substrates; may have gradients in powders. |

| Rotary Furnace | Continuous mixing | Best for powders/granules; ensures even exposure to heat sources. |

Struggling with uneven heating in your experiments? KINTEK specializes in advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Tube Furnaces, Rotary Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique requirements. Whether you're processing powders, granules, or solid substrates, our expertise ensures precise temperature control and uniformity. Contact us today to discuss how we can optimize your lab's performance and achieve reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing