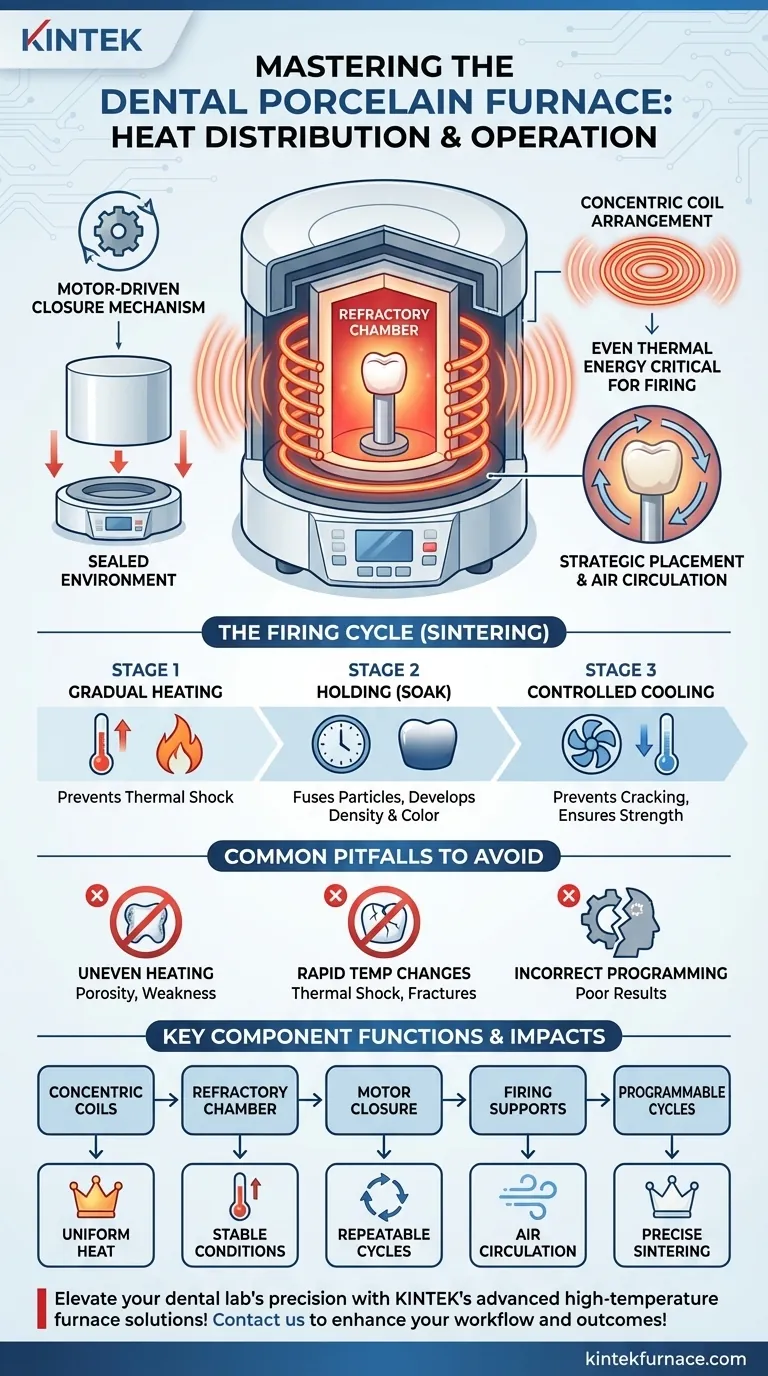

At its core, a porcelain furnace operates using a simple yet precise system: a motor-driven mechanism seals a refractory chamber, where heating coils arranged concentrically around the dental restoration distribute heat uniformly. This design ensures that every surface of the ceramic receives even thermal energy, which is critical for the firing process.

The fundamental challenge in firing dental porcelain is not merely reaching a high temperature, but achieving perfectly uniform heat in a highly controlled environment. The entire design of a modern furnace, from its mechanical closure to its coil placement, is engineered to master this single objective.

The Firing Chamber: A Controlled Environment

The entire process begins and ends with the furnace's ability to create a sealed, stable, and predictable heating environment. This is accomplished through its primary mechanical and material components.

The Closing Mechanism

A motor-driven mechanism is responsible for closing the chamber. This happens in one of two ways: either the firing platform holding the restoration is raised into the upper housing, or the upper housing containing the heating elements is lowered onto the base.

The goal of both methods is identical: to create a sealed environment that prevents heat from escaping and external contaminants from entering, ensuring the firing cycle is predictable and repeatable.

The Role of the Refractory Chamber

The firing chamber itself is a refractory unit. This means it is constructed from materials specifically designed to withstand and contain extremely high temperatures without deforming or breaking down.

This material integrity is crucial for maintaining a stable temperature throughout the lengthy firing and cooling cycles.

Achieving Uniform Heat Distribution

The quality of the final restoration is directly dependent on how evenly heat is applied. Any hot spots or cold spots can compromise the material's strength and aesthetics.

Concentric Coil Arrangement

The heating coils are not placed arbitrarily; they are arranged concentrically around the restoration. Imagine ripples spreading from the center of a pond—this is how heat radiates inward from the coils.

This circular, layered arrangement ensures that thermal energy converges on the restoration from all sides simultaneously, providing the most even heat distribution possible.

Strategic Placement of Restorations

Restorations are never placed directly on the chamber floor. Instead, they are set on supports like ceramic pins, mesh, or firing pads.

This small detail is critical, as it elevates the piece and allows hot air to circulate completely around it, including underneath. This eliminates the risk of a cold spot on the restoration's base and ensures it is heated uniformly from top to bottom.

Understanding the Firing Cycle (Sintering)

The operation of the furnace is defined by the firing cycle, a carefully programmed sequence of heating and cooling stages that transforms porcelain powder into a dense, solid material. This process is technically known as sintering.

Gradual Heating and Holding

The cycle begins with a gradual increase in temperature. This slow ramp-up prevents thermal shock and allows the entire volume of the ceramic to heat at the same rate.

Once the target temperature is reached, it is held for a specific period. This "hold" or "soak" time allows the desired chemical and physical changes to occur, fusing the ceramic particles to achieve optimal density and color stability.

Controlled Cooling

Just as important as the heating is the cooling. The furnace controls the rate of temperature decrease to prevent the new ceramic structure from cracking or developing internal stresses, which ensures its final strength and longevity.

Programmable Cycles for Precision

Modern furnaces feature programmable firing cycles with pre-set profiles. Technicians can select the exact program designed for a specific material, whether it's for an initial build-up, a final glaze, or the crystallization of a glass-ceramic.

Common Pitfalls to Avoid

Even with a perfect furnace, user error or a misunderstanding of the principles can lead to failed restorations.

The Risk of Uneven Heating

If a restoration is placed too close to a heating element or improperly supported, it will heat unevenly. This can lead to porosity, poor color matching, and internal stresses that make the final crown or veneer weak and prone to fracture.

The Danger of Rapid Temperature Changes

Rushing the heating or cooling cycle is a common mistake that induces thermal shock. This is the primary cause of cracks and fractures in ceramic restorations.

The Importance of Correct Programming

Using a firing cycle that does not match the ceramic manufacturer's specifications is a guaranteed way to achieve a poor result. Each material has a unique composition that requires a specific heat and time profile to mature correctly.

Making the Right Choice for Your Goal

Understanding how the furnace operates allows you to control the variables that matter most for your desired outcome.

- If your primary focus is aesthetics and color stability: Pay close attention to the hold time at peak temperature, as this is when the material's optical properties fully develop.

- If your primary focus is strength and longevity: Ensure the heating and cooling rates are gradual to eliminate internal stress and porosity, which are the main culprits behind clinical failures.

- If your primary focus is efficiency and repeatability: Rely on the furnace's pre-set programs and ensure you are matching the correct program to the specific ceramic you are using.

By mastering these principles, you move from simply operating a machine to truly engineering a successful dental restoration.

Summary Table:

| Component/Process | Key Function | Impact on Firing |

|---|---|---|

| Concentric Coils | Distribute heat uniformly around restoration | Prevents hot/cold spots for even material properties |

| Refractory Chamber | Withstands high temperatures and seals environment | Maintains stable, predictable firing conditions |

| Motor-Driven Closure | Seals chamber by raising platform or lowering housing | Ensures repeatable cycles and prevents contamination |

| Firing Supports (e.g., pins, mesh) | Elevate restoration for air circulation | Eliminates cold spots and promotes uniform heating |

| Programmable Cycles | Control heating, holding, and cooling stages | Enables precise sintering for density, color, and strength |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering uniform heat distribution and controlled firing for flawless dental restorations. Contact us today to discuss how our solutions can enhance your workflow and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations