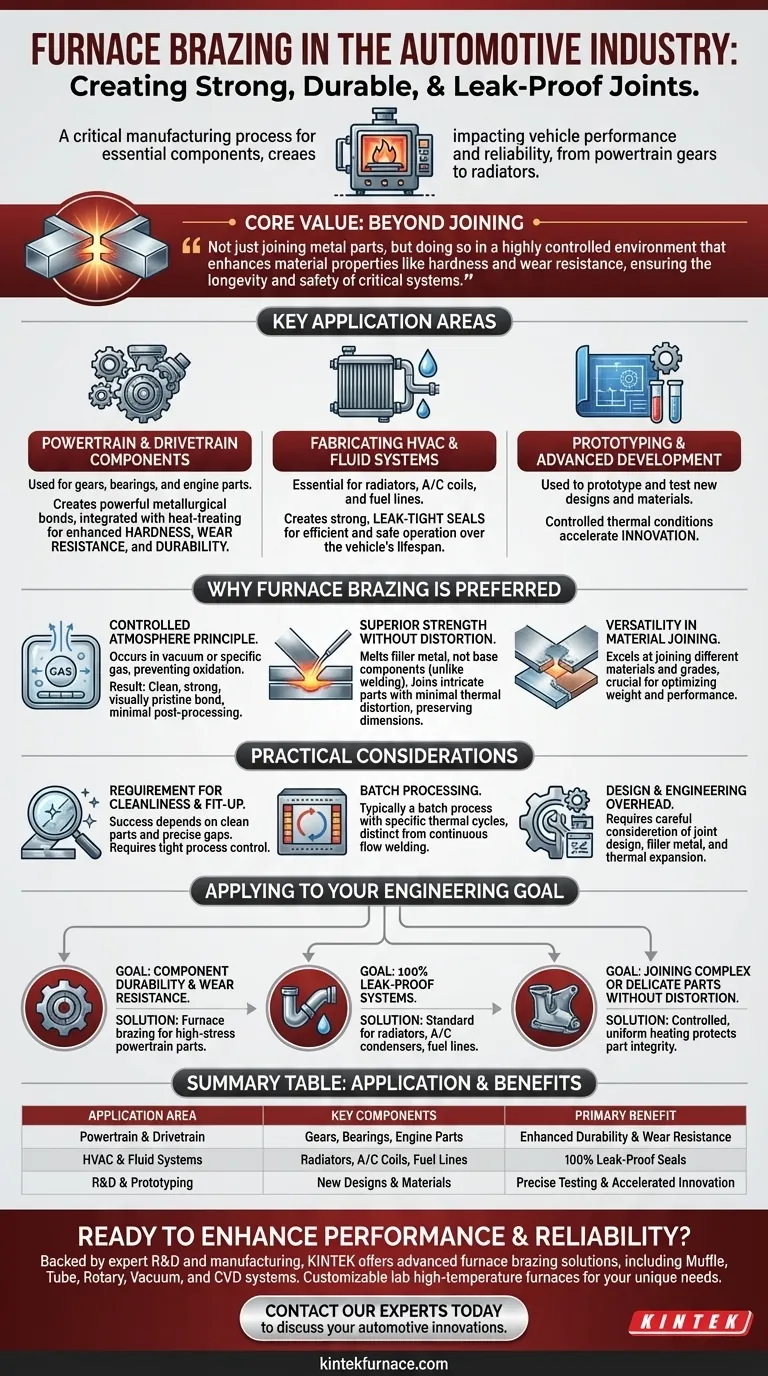

In the automotive industry, furnace brazing is a critical manufacturing process used to create strong, durable, and leak-proof joints for essential components. It is the method of choice for parts ranging from powertrain gears and engine components to radiators and air conditioning systems, directly impacting vehicle performance and reliability.

The core value of furnace brazing in automotive applications is not just joining metal parts, but doing so in a highly controlled environment that enhances material properties like hardness and wear resistance, ensuring the longevity and safety of critical systems.

The Role of Furnace Brazing in Automotive Manufacturing

Furnace brazing is not a one-size-fits-all solution; it is applied strategically where joint integrity and material enhancement are paramount. Its use is concentrated in systems that experience high stress, temperature variations, or require absolute sealing.

Joining Powertrain and Drivetrain Components

The process is heavily used for components like gears, bearings, and various engine parts.

By heating the assembly in a controlled furnace, the brazing process creates a powerful metallurgical bond. This not only joins the parts but can also be integrated with heat-treating, enhancing the hardness, wear resistance, and overall durability of the final component.

Fabricating HVAC and Fluid Systems

Furnace brazing is essential for producing heating, ventilation, and air conditioning (HVAC) assemblies.

Components such as radiators, air conditioning coils, and fuel lines rely on this method to create strong, leak-tight seals. This ensures that refrigerant and fuel systems operate efficiently and safely without leakage over the vehicle's lifespan.

Prototyping and Advanced Development

Beyond mass production, furnace brazing is a key tool in automotive research and development.

Engineers use the process to prototype and test new designs for a wide variety of parts. The controlled thermal conditions of a furnace allow for precise study of how new materials and joint configurations behave, accelerating innovation.

Why Furnace Brazing is the Preferred Method

The preference for furnace brazing over other joining methods, like welding, stems from its unique advantages in control, precision, and the quality of the final joint.

The Principle of a Controlled Atmosphere

Furnace brazing occurs within a sealed environment, often a vacuum or a specific gas atmosphere.

This controlled environment prevents oxidation and other contaminants from compromising the joint. The result is a clean, strong, and visually pristine bond that requires little to no post-processing.

Superior Joint Strength Without Distortion

The process works by melting a filler metal that flows between the base components, which do not melt themselves.

This is a critical distinction from welding. It allows for the joining of intricate or thin-walled parts with minimal thermal distortion, preserving their original dimensions and mechanical properties while creating a robust, uniform bond.

Versatility in Material Joining

Furnace brazing excels at joining materials with different properties, such as different grades of steel or even non-ferrous metals found in cooling systems. This flexibility is crucial for modern vehicle designs that use a mix of materials to optimize weight and performance.

Understanding the Practical Considerations

While highly effective, furnace brazing is a specialized process with specific requirements that make it ideal for certain applications but less so for others.

Requirement for Cleanliness and Fit-Up

The success of a brazed joint depends entirely on the cleanliness of the parts and the precise gap between them. Any contaminants or incorrect tolerances will prevent the filler metal from properly wetting the surfaces and creating a strong bond, demanding tight process control.

Batch Processing vs. Continuous Flow

Furnace brazing is typically a batch process, where parts are loaded into a furnace for a specific thermal cycle. This can be less suited for the high-speed, continuous flow of some automotive assembly lines compared to instantaneous processes like robotic welding.

Design and Engineering Overhead

Properly designing a component for furnace brazing requires careful consideration of joint design, filler metal selection, and thermal expansion rates. This adds an engineering requirement upfront to ensure the process is successful and repeatable.

Applying Furnace Brazing to Your Goal

To leverage this process effectively, align the method with your specific engineering objective.

- If your primary focus is component durability and wear resistance: Furnace brazing is the ideal choice for high-stress powertrain parts like gears and engine assemblies.

- If your primary focus is creating 100% leak-proof systems: This is the standard for fabricating reliable radiators, A/C condensers, and fuel lines.

- If your primary focus is joining complex or delicate parts without distortion: The controlled, uniform heating of furnace brazing protects part integrity better than localized welding.

Ultimately, furnace brazing is a precision technology that enables the production of higher-performing and more reliable automotive components.

Summary Table:

| Application Area | Key Components | Primary Benefit |

|---|---|---|

| Powertrain & Drivetrain | Gears, Bearings, Engine Parts | Enhanced Durability & Wear Resistance |

| HVAC & Fluid Systems | Radiators, A/C Coils, Fuel Lines | 100% Leak-Proof Seals |

| R&D & Prototyping | New Designs & Materials | Precise Testing & Accelerated Innovation |

Ready to enhance the performance and reliability of your automotive components?

Backed by expert R&D and manufacturing, KINTEK offers advanced furnace brazing solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are all customizable to meet your unique production or prototyping needs for creating strong, durable, and leak-proof joints.

Contact our experts today to discuss how our brazing technology can drive your automotive innovations forward.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control