In essence, the sintering process for dental zirconia has been a transformative innovation because it enables the conversion of a soft, chalk-like material into a final dental restoration with immense strength, exceptional aesthetics, and precise fit. This technology has fundamentally streamlined the creation of crowns, bridges, and implants, dramatically reducing production time and costs while increasing safety and reliability.

The true innovation of zirconia sintering is its ability to merge three critical dental objectives—durability, aesthetics, and efficiency—into a single, digitally-driven workflow that was previously unattainable with traditional methods.

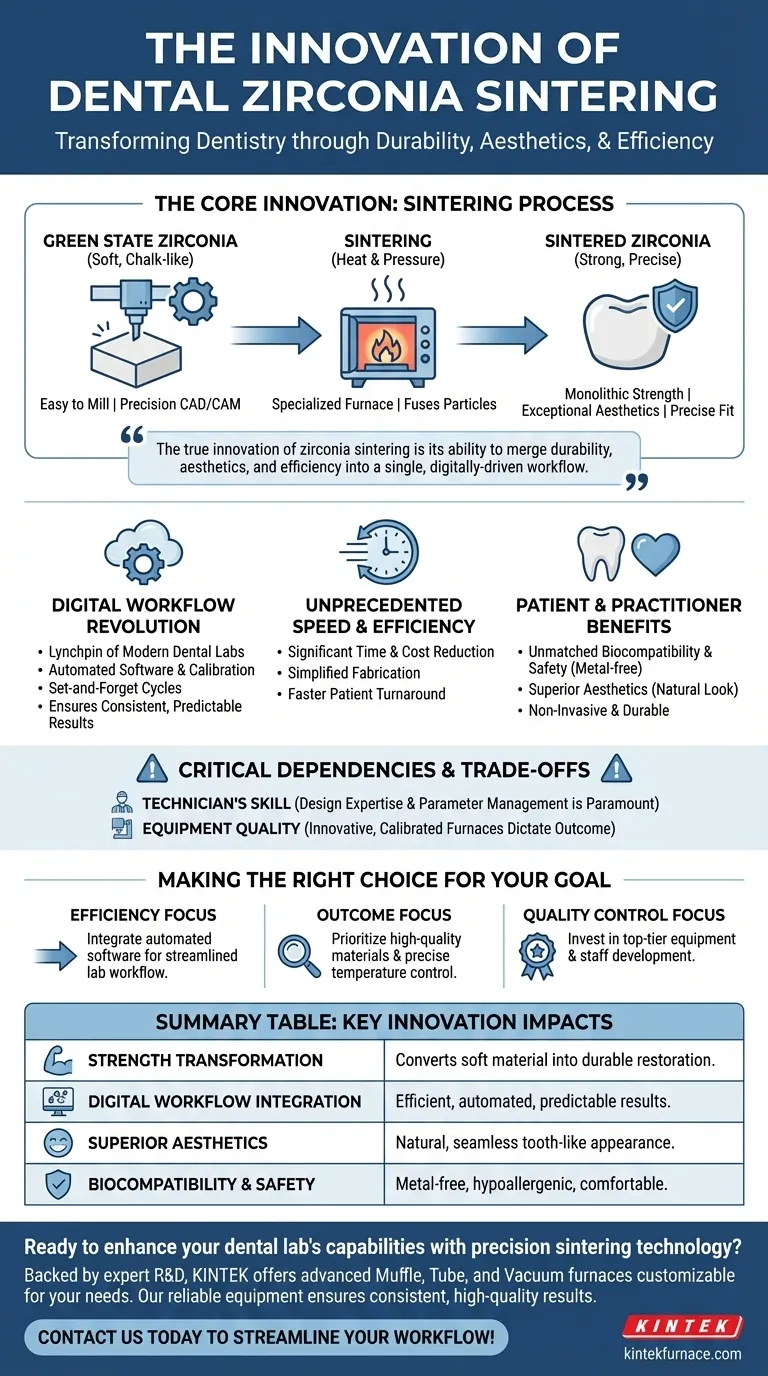

How Sintering Fundamentally Changed Restorative Dentistry

The introduction of sintering didn't just improve an existing process; it created an entirely new paradigm for dental labs and practitioners. It is the critical final step that unlocks the full potential of modern digital dentistry.

From Brittle to Unbreakable

Before sintering, zirconia is in a soft, "green state," which is easy to mill with high precision using CAD/CAM technology. The sintering process then heats this milled form in a specialized furnace under immense pressure. This fuses the zirconia particles together, creating a monolithic, incredibly strong final product that can withstand the forces of chewing.

The Digital Workflow Revolution

Sintering is the lynchpin of the modern digital dental workflow. Modern furnaces incorporate automated software and calibration tools, allowing for "set-and-forget" cycles. This integration saves significant time and reduces the potential for human error, ensuring consistent and predictable results every time.

Achieving Unprecedented Speed and Efficiency

By simplifying the fabrication process, sintering has led to significant reductions in both labor time and material costs. What once required complex, multi-step procedures can now be managed through a more automated and efficient system, allowing for faster turnaround for patients.

The Tangible Benefits for Patients and Practitioners

The advantages of sintered zirconia extend directly to patient safety, comfort, and long-term dental health, providing a clear benefit for clinicians to offer.

Unmatched Biocompatibility and Safety

Sintered zirconia is a metal-free ceramic, eliminating the risk of allergic reactions common with older metal-based restorations. The process itself involves low radiation, and modern temperature-controlled equipment minimizes the risk of fractures or chipping, enhancing the safety of the final restoration.

Superior Aesthetics and a Natural Look

One of the most significant patient benefits is the material's natural, tooth-like color. It blends seamlessly with surrounding teeth, providing a superior cosmetic appearance that is difficult to achieve with traditional materials like porcelain-fused-to-metal crowns.

A Non-Invasive and Durable Solution

In many cases, fitting a zirconia restoration does not require the aggressive removal of healthy tooth structure. Once sintered and placed, the restoration is exceptionally durable and comfortable, providing a strong, fully functional, and long-lasting replacement for weak or damaged teeth.

Understanding the Critical Dependencies and Trade-offs

While the technology is powerful, the final outcome is not guaranteed. The quality of a sintered zirconia restoration is highly dependent on two key factors that cannot be overlooked.

The Technician's Skill is Paramount

The most advanced furnace cannot compensate for poor design or preparation. The expertise of the dental technician in designing the restoration and managing the sintering parameters is absolutely critical for creating a high-quality, perfectly fitting product.

Equipment Quality Dictates the Outcome

Consistency and precision depend entirely on the quality of the sintering furnace. Utilizing innovative, well-calibrated equipment is essential for achieving the correct material density and strength. Choosing a lab or provider that invests in top-tier equipment is vital for predictable results.

Making the Right Choice for Your Goal

To leverage this technology effectively, align your approach with your primary objective.

- If your primary focus is practice efficiency: Integrate sintering furnaces that feature automated software to streamline your lab's workflow and reduce hands-on labor time.

- If your primary focus is patient outcomes: Prioritize high-quality zirconia materials and precise temperature control to achieve the ideal balance of natural aesthetics and long-term durability.

- If your primary focus is quality control: Invest in top-tier equipment and the continuous professional development of your technical staff, as they remain the most critical variables in the final product.

Ultimately, mastering the zirconia sintering process empowers dental professionals to deliver a higher standard of care with greater predictability and confidence.

Summary Table:

| Key Innovation | Impact on Dentistry |

|---|---|

| Strength Transformation | Converts soft, millable zirconia into a monolithic, durable final restoration. |

| Digital Workflow Integration | Enables efficient, automated "set-and-forget" cycles for consistent, predictable results. |

| Superior Aesthetics | Achieves a natural, tooth-like appearance that blends seamlessly with surrounding teeth. |

| Biocompatibility & Safety | Provides a metal-free, hypoallergenic solution, enhancing patient safety and comfort. |

Ready to enhance your dental lab's capabilities with precision sintering technology?

Backed by expert R&D and manufacturing, KINTEK offers advanced laboratory furnaces, including Muffle, Tube, and Vacuum systems, all customizable for your unique dental sintering needs. Our reliable equipment ensures the consistent, high-quality results your practice depends on.

Contact us today to discuss how our solutions can streamline your workflow and elevate the quality of your dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time