Choosing the right dental furnace is a decision directly driven by your operational demands. At its core, your workload and capacity needs determine the required chamber size and cycle speed of the furnace to ensure you can meet current production volumes and accommodate future growth without creating a workflow bottleneck.

Beyond simply fitting more restorations, matching a furnace to your workload is about optimizing your entire workflow for efficiency and profitability. The right choice prevents production bottlenecks, minimizes operational costs per unit, and ensures your investment remains viable as your practice or lab grows.

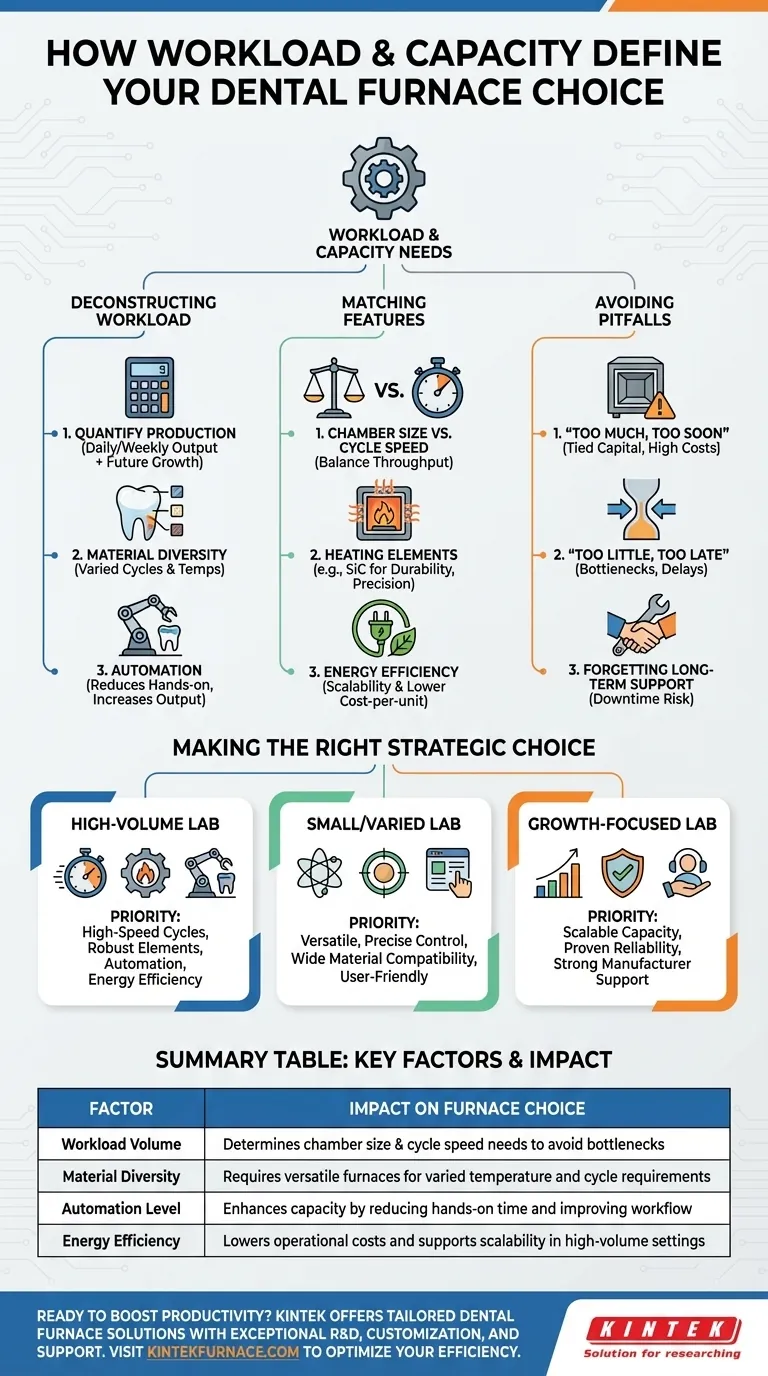

Deconstructing Your Workload: Beyond Simple Volume

To make an informed decision, you must analyze your workload with a level of detail that goes beyond a simple daily count.

Calculating Your True Capacity Needs

Your first step is to quantify your production. Analyze your average daily and weekly output for all restorations that require firing or sintering.

Critically, you must also project your growth. A furnace that is perfect for your needs today may become a limiting factor in two years. Planning for future demand prevents the need for a premature and costly upgrade.

The Role of Material Diversity

Your capacity is not just about the number of units but also the types of materials you use. A lab specializing in high-volume zirconia will have different firing cycle requirements than a boutique lab focused on complex, multi-layered porcelain cases.

Different materials require different temperatures, ramp rates, and cycle durations. A diverse material portfolio means your furnace must be versatile, which can impact its overall daily throughput.

The Human Factor: Automation and Ease of Use

In a high-workload environment, technician time is a valuable resource. A furnace's capacity is directly enhanced by features that reduce hands-on requirements.

Look for furnaces with extensive pre-programmed cycles, intuitive touchscreen interfaces, and software integration. These automation features free up your team to focus on other value-added tasks, effectively increasing your lab's total operational capacity.

Matching Furnace Features to Production Demands

Once you understand your workload, you can translate those needs into specific technical features.

Chamber Size vs. Cycle Speed

It is easy to assume that a larger chamber is always better, but this is a simplification. The true measure of throughput is a balance between chamber size and cycle speed.

A large-chamber furnace with a very long cycle may be less productive than a smaller, faster furnace that can complete multiple cycles in the same amount of time. For labs requiring quick turnarounds, speed and efficiency (including ramp rates and cooling) are often more critical than raw size.

Heating Elements and Temperature Control

For high-demand environments, the durability of the heating elements is paramount. Elements made from materials like silicon carbide (SiC) are known for their longevity and reliability under constant use.

Furthermore, precise temperature control and uniform heat distribution are non-negotiable. Inconsistent firing leads to remakes, which directly damages your productivity and eats into your capacity.

Energy Efficiency as a Scalability Factor

In a small lab, the energy consumption of a furnace may seem minor. In a high-volume production setting, however, it becomes a significant operational cost.

Some modern furnaces offer substantial energy-saving functions—up to 40% in some cases. At scale, this efficiency directly reduces your cost-per-unit and makes your operation more profitable and scalable.

Understanding the Trade-offs and Common Pitfalls

Choosing a furnace involves balancing competing priorities. Being aware of common mistakes can save you significant time and money.

The "Too Much, Too Soon" Trap

Purchasing a large, industrial-scale furnace for a small but growing lab can be a mistake. You tie up significant capital in capacity you won't use for years while paying for higher energy consumption and a larger footprint.

The "Too Little, Too Late" Bottleneck

The more common error is underestimating growth. A furnace that is at 90% capacity on day one will quickly become a major bottleneck, limiting your ability to take on new clients, forcing staff into overtime, and delaying delivery times.

Forgetting Long-Term Support

A high-workload furnace is a workhorse that will eventually require service and maintenance. Opting for a cheaper model from a manufacturer with a poor reputation for after-sales support is a critical error. When that furnace goes down, your entire production line can grind to a halt, making any initial savings irrelevant.

Making the Right Choice for Your Goal

Your decision should be a strategic one based on your specific operational profile.

- If your primary focus is a high-volume production lab: Prioritize furnaces with high-speed cycles, robust heating elements (like SiC), significant automation, and proven energy efficiency to lower your cost-per-unit.

- If your primary focus is a small or in-office lab with varied cases: Focus on a versatile furnace with precise temperature control, compatibility with a wide range of materials, and a user-friendly interface for quick cycle programming.

- If your primary focus is future growth and scalability: Invest in a model with slightly more capacity than you currently need, but place the highest priority on proven reliability and strong manufacturer support to avoid costly downtime.

By analyzing your workflow, not just your volume, you can select a furnace that serves as a powerful engine for growth rather than a limit on your potential.

Summary Table:

| Factor | Impact on Furnace Choice |

|---|---|

| Workload Volume | Determines chamber size and cycle speed needs to avoid bottlenecks |

| Material Diversity | Requires versatile furnaces for varied temperature and cycle requirements |

| Automation Level | Enhances capacity by reducing hands-on time and improving workflow |

| Energy Efficiency | Lowers operational costs and supports scalability in high-volume settings |

Ready to boost your lab's productivity with a tailored dental furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, helping you optimize efficiency and scale for the future. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations