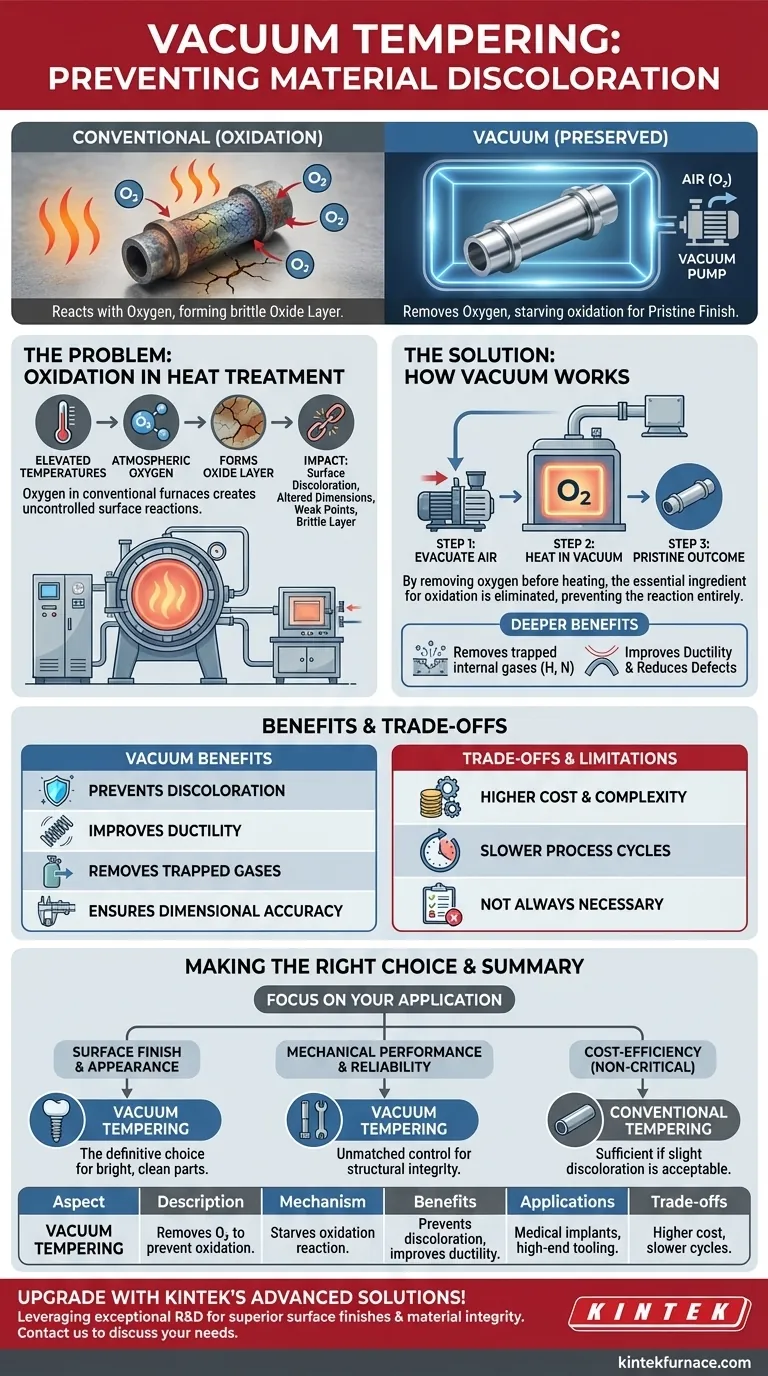

To be precise, vacuum tempering prevents discoloration by removing the atmospheric oxygen required for oxidation to occur. By heating the material in a near-vacuum, the chemical reaction that forms a discolored oxide layer on the metal's surface is effectively starved of its key ingredient, preserving the material's original finish and structural integrity.

The absence of oxygen in a vacuum furnace is the key. It shifts the goal from simply managing unpredictable surface reactions to achieving precise, repeatable control over the material's final properties, ensuring both visual and structural quality.

The Fundamental Problem: Oxidation in Heat Treatment

To understand why vacuum is so effective, we must first understand the problem it solves. The discoloration seen after conventional heat treatment is a direct result of oxidation.

What is Oxidation?

At elevated temperatures, metals like steel become highly reactive with the elements in the air. The most significant reaction is with oxygen.

This reaction forms a thin layer of metallic oxide on the material's surface. This oxide layer is what you perceive as discoloration, scale, or tarnish.

The Impact of a Contaminated Surface

This oxide layer is not just a cosmetic issue. It is a new, often brittle ceramic material formed on top of your metal part.

This layer can alter the precise dimensions of a component, flake off during use, and create a weak point for cracks or corrosion to begin. It fundamentally compromises the intended surface properties of the material.

The Conventional Atmosphere Challenge

Standard air is approximately 78% nitrogen and 21% oxygen, with traces of other gases and water vapor.

When a part is heated in a conventional furnace, it is bathed in this reactive atmosphere. The result is an uncontrolled and often undesirable chemical reaction on the part's surface, leading to oxidation and discoloration.

How Vacuum Provides the Solution

A vacuum furnace works by fundamentally changing the environment. Instead of trying to manage reactive gases, it removes them almost entirely.

Eliminating the Reactants

The primary function of the vacuum pump is to evacuate the air from the furnace chamber before the heating cycle begins.

By removing the oxygen, the process eliminates the essential component needed for oxidation. Without available oxygen atoms, the oxide layer simply cannot form, even at high tempering temperatures.

Preserving a Pristine Surface

The direct result is a component that exits the furnace with the same clean, bright surface it had when it went in.

This is critical for parts where appearance is important, such as medical implants or high-end tooling, and for components requiring tight dimensional tolerances where any surface scale is unacceptable.

Improving Deeper Material Properties

The benefits of a vacuum environment extend beyond the surface. A strong vacuum can also pull dissolved gases, like hydrogen and nitrogen, out from within the metal itself.

Removing these trapped gases can significantly improve the material's ductility and reduce the risk of internal defects or hydrogen embrittlement. This leads to a part that is not only visually perfect but also structurally superior.

Understanding the Trade-offs

While vacuum tempering offers superior results, it is essential to recognize the trade-offs involved in the process. Objectivity requires acknowledging its limitations.

Equipment Cost and Complexity

Vacuum furnaces are significantly more complex and expensive than their conventional atmosphere counterparts. They require robust vacuum pumps, precise seals, and sophisticated control systems, all of which increase capital investment and maintenance costs.

Slower Process Cycles

Achieving a deep vacuum takes time. The pump-down phase adds to the overall cycle time for each batch, potentially reducing throughput compared to a simple atmospheric furnace.

Not a Universal Necessity

For many low-carbon steel parts where surface finish is not a primary concern and a slight oxide layer is acceptable or even desired for paint adhesion, conventional tempering is a more cost-effective and faster solution.

Making the Right Choice for Your Application

Selecting the correct heat treatment process depends entirely on the requirements of your final product.

- If your primary focus is surface finish and appearance: Vacuum tempering is the definitive choice to guarantee a bright, clean, and unoxidized part right out of the furnace.

- If your primary focus is mechanical performance and reliability: The vacuum process offers unmatched control, preventing brittle oxide layers and removing trapped gases that can compromise structural integrity.

- If your primary focus is cost-efficiency on non-critical parts: Conventional tempering may be sufficient, provided some surface discoloration and potential post-processing (like cleaning or shot blasting) are acceptable.

Ultimately, choosing a vacuum process is an investment in certainty—delivering predictable quality from the surface all the way to the core.

Summary Table:

| Aspect | Description |

|---|---|

| Mechanism | Removes oxygen to prevent oxidation, preserving material finish and structural integrity. |

| Benefits | Prevents discoloration, improves ductility, removes trapped gases, and ensures dimensional accuracy. |

| Applications | Ideal for medical implants, high-end tooling, and parts requiring tight tolerances and visual appeal. |

| Trade-offs | Higher equipment cost, slower process cycles, and may not be necessary for non-critical parts. |

Upgrade your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, guaranteeing superior surface finishes and material integrity. Contact us today to discuss how we can enhance your results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance