The temperature setting of a laboratory high-temperature muffle furnace is the primary determinant of biochar quality, specifically influencing the crystalline arrangement and porosity of coconut husk. Increasing the pyrolysis temperature to 600°C provides the necessary thermal energy to fundamentally reorganize the biochar's carbon skeleton. This structural shift is essential for transitioning the material from a raw biomass state into a highly effective adsorbent.

Core Takeaway: While lower temperatures initiate carbonization, a pyrolysis temperature of 600°C is required to maximize crystallinity and develop the microporous structure necessary for high-performance applications, such as lead ion adsorption.

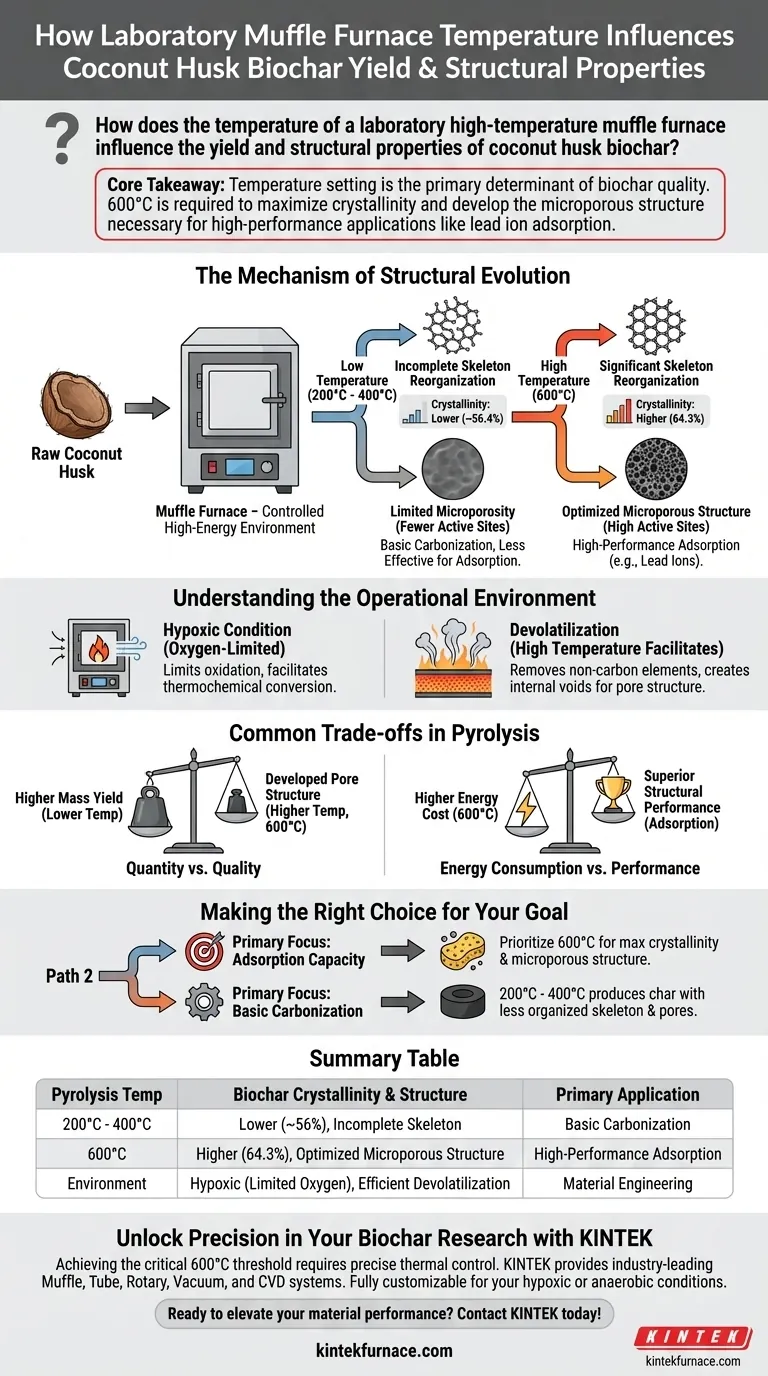

The Mechanism of Structural Evolution

Energy and Skeleton Reorganization

The muffle furnace does not simply burn the material; it provides a controlled, high-energy environment that drives gradient pyrolysis.

At lower temperatures (200°C or 400°C), the heat is insufficient to fully alter the carbon matrix. However, at 600°C, the thermal energy supplied is high enough to promote the reorganization of the biochar skeleton.

The Shift in Crystallinity

This reorganization is quantifiable through the material's crystallinity.

Research indicates that raising the temperature to 600°C causes a significant increase in crystallinity, jumping from 56.4% to 64.3%. This increase signifies a more ordered, stable carbon structure compared to biochars produced at lower temperatures.

Development of Microporosity

The physical outcome of this chemical reorganization is the formation of a highly developed microporous structure.

These micropores are the "active sites" of the biochar. Without the high heat of 600°C, these pores do not fully develop, rendering the biochar less effective for tasks requiring surface interaction, such as the adsorption of heavy metals.

Understanding the Operational Environment

The Hypoxic Condition

Unlike tube furnaces that often use active nitrogen flow to create strictly anaerobic conditions, a muffle furnace typically provides a hypoxic (oxygen-limited) environment.

By heating the coconut husk in a confined space (often utilizing containment like aluminum foil boxes), the furnace limits oxidation while facilitating thermochemical conversion.

Devolatilization

The high temperature facilitates the efficient removal of volatile components (devolatilization).

As the temperature rises, non-carbon elements are driven off. This creates the internal voids that become the pore structure, leaving behind a carbon-rich precursor with a stable architecture.

Common Trade-offs in Pyrolysis

Quantity vs. Quality

There is an inherent trade-off between the mass yield and the structural quality of the biochar.

While lower temperatures might result in a higher mass yield (because fewer volatiles are burned off), the resulting material lacks the developed pore structure required for advanced applications.

Energy Consumption vs. Performance

Operating at 600°C requires significantly more energy than operating at 200°C or 400°C.

However, the primary reference suggests that this energy expenditure is necessary. If the goal is performance—specifically lead ion adsorption—the structural benefits of the 600°C threshold outweigh the energy costs.

Making the Right Choice for Your Goal

To optimize your coconut husk biochar production, consider your specific end-use requirements:

- If your primary focus is Adsorption Capacity: Prioritize a temperature of 600°C to maximize crystallinity (64.3%) and ensure a fully developed microporous structure for trapping contaminants like lead ions.

- If your primary focus is Basic Carbonization: Temperatures between 200°C and 400°C will produce char, but be aware that the carbon skeleton will remain less organized and the pore structure significantly less effective.

Ultimately, for high-value applications, the energy investment of reaching 600°C is mandatory to unlock the full structural potential of coconut husk biochar.

Summary Table:

| Pyrolysis Temperature | Biochar Crystallinity | Structural Development | Primary Application |

|---|---|---|---|

| 200°C - 400°C | Lower (approx. 56%) | Incomplete Skeleton Reorganization | Basic Carbonization |

| 600°C | Higher (64.3%) | Optimized Microporous Structure | High-Performance Adsorption (e.g., Lead Ions) |

| Environment | Hypoxic (Limited Oxygen) | Efficient Devolatilization | Material Engineering |

Unlock Precision in Your Biochar Research with KINTEK

Achieving the critical 600°C threshold for optimal carbon skeleton reorganization requires reliable and precise thermal control. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of laboratory research and material science.

Backed by expert R&D and manufacturing, our furnaces are fully customizable to ensure your specific pyrolysis conditions—whether hypoxic or strictly anaerobic—are met with 100% accuracy.

Ready to elevate your material performance? Contact KINTEK today to find the perfect high-temperature furnace for your lab!

Visual Guide

References

- Adil Ahmed, Perumal Asaithambi. Valorization of coconut husk into biochar for lead (Pb <sup>2+</sup> ) adsorption. DOI: 10.1515/gps-2024-0230

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a box-type resistance furnace utilized for long-duration heat preservation of chromium steel? Key Benefits

- What are the benefits of programmable controls in a muffle furnace? Unlock Precision and Automation for Your Lab

- What roles do programmable laboratory high-temperature furnaces play in calcium perrhenate single crystal preparation?

- What materials can crucible furnaces melt? A Guide to Metals, Glass & Advanced Materials

- Why is a secondary annealing treatment in a muffle furnace necessary for coated ceramic sensor components?

- How does a precision temperature-controlled sintering furnace ensure the structural quality of PTFE/Fe2O3 composites?

- What is the function of a high-temperature muffle furnace in BCZT ceramic synthesis? Optimize Phase Transformation

- Why are muffle furnaces important for determining moisture, ash, and volatile content in pharmaceutical materials? Ensure Purity and Compliance