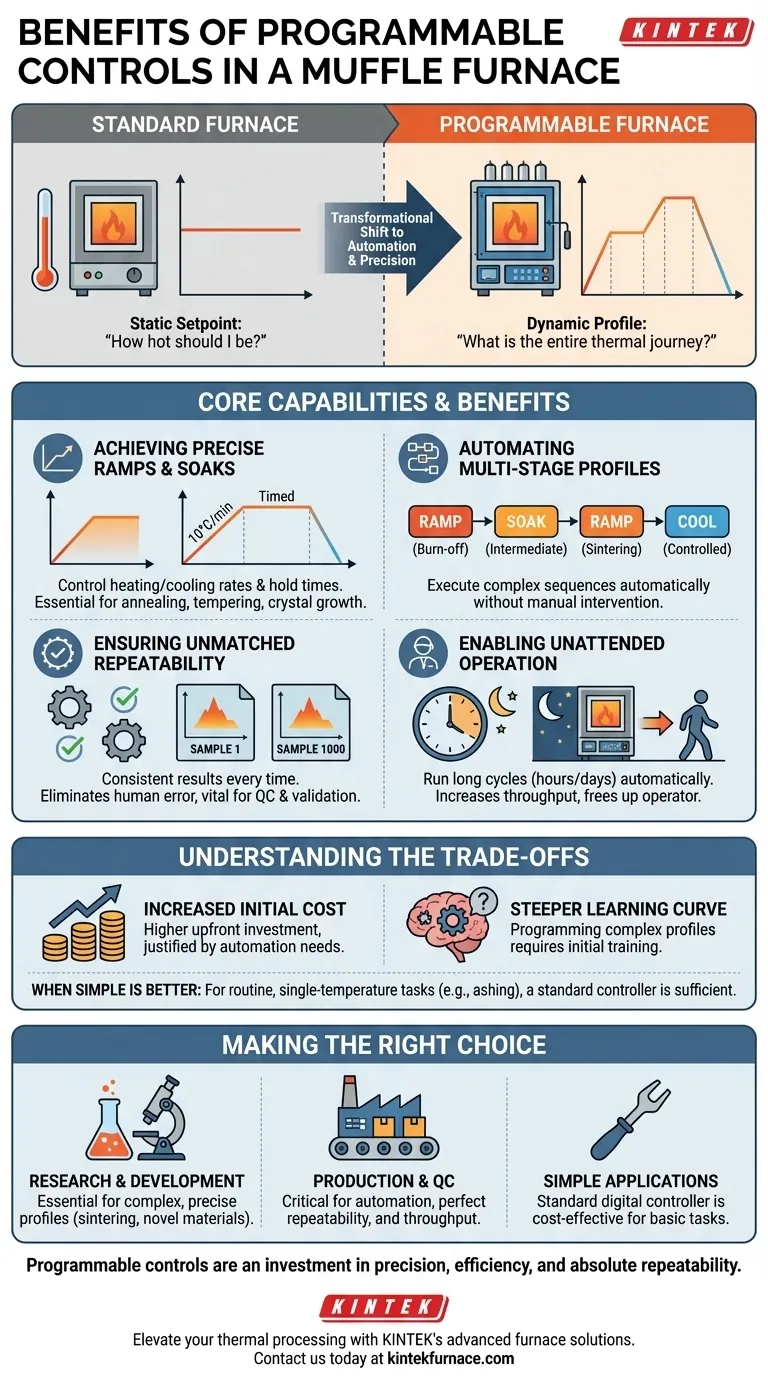

Programmable controls transform a muffle furnace from a simple high-temperature oven into a precise, automated thermal processing instrument. While a standard furnace can hold a set temperature, a programmable furnace can execute complex, multi-stage heating and cooling cycles automatically, unlocking advanced capabilities for research, development, and quality control.

A standard furnace asks, "How hot should I be?" A furnace with programmable controls asks, "What is the entire thermal journey this material needs to take?" This shift from a static setpoint to a dynamic profile is the key to process automation, repeatability, and sophisticated material treatment.

The Core Capabilities of Programmable Controls

Programmable controls provide a level of command over the thermal process that is impossible to achieve manually. This unlocks several critical capabilities that are essential for advanced applications.

Achieving Precise Ramps and Soaks

A thermal process is often more than just a single temperature. A ramp is the rate at which temperature changes (e.g., 10°C per minute), and a soak is a period of holding a specific temperature for a set duration.

Programmable controls allow you to define these rates and times with precision, which is crucial for processes like annealing, tempering, and crystal growth where the heating and cooling curve directly impacts the final material properties.

Automating Multi-Stage Thermal Profiles

Many advanced processes require a sequence of different temperatures and hold times. For example, a ceramic sintering process might involve a slow ramp to burn off binders, a soak at an intermediate temperature, a fast ramp to a high sintering temperature, and then a controlled cool-down.

A programmable controller executes this entire multi-step profile without any manual intervention, ensuring the process runs exactly as designed every time.

Ensuring Unmatched Repeatability

In scientific research and industrial quality control, consistency is paramount. Programmable controls eliminate the human error and variability associated with manual timing and temperature adjustments.

By automating the process, you guarantee that every sample, from the first to the thousandth, undergoes the exact same thermal treatment. This repeatability is fundamental to validating results and maintaining product quality.

Enabling Unattended Operation

Complex thermal cycles can take many hours or even days. Programmable controls allow you to set the entire process and let it run unattended, even overnight or over a weekend.

This dramatically increases laboratory or production throughput by freeing up operator time and utilizing furnace downtime for long processes.

Understanding the Trade-offs

While powerful, programmable controls are not the default choice for every situation. Understanding the trade-offs ensures you select the right tool for the job.

Increased Initial Cost

Furnaces equipped with advanced programmable controllers typically have a higher upfront cost compared to models with basic, single-setpoint digital controllers. This investment must be justified by the need for process automation and complexity.

A Steeper Learning Curve

Programming a multi-stage thermal profile is inherently more complex than setting a single temperature. Users may need a brief training period to become comfortable with the controller's interface and programming logic.

When Simple Is Better

For many routine applications, such as simple ashing, moisture determination, or basic heat-treating at one temperature, a programmable controller is unnecessary. A standard digital controller is more cost-effective, simpler to operate, and perfectly sufficient for these tasks.

Making the Right Choice for Your Application

The decision to invest in programmable controls should be driven entirely by the demands of your thermal process.

- If your primary focus is research or materials development: Programmable controls are virtually essential for executing the complex and precise thermal profiles needed for sintering, annealing, and creating novel materials.

- If your primary focus is production or quality control: The automation and perfect repeatability of programmable controls are critical for ensuring every batch meets the exact same process standard and for maximizing throughput.

- If your primary focus is simple, single-temperature applications: A standard digital controller is more cost-effective and perfectly suited for basic tasks like drying or ashing where process automation is not required.

Ultimately, choosing programmable controls is an investment in process precision, operational efficiency, and the absolute repeatability of your results.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Ramps and Soaks | Control heating/cooling rates and hold times for accurate thermal profiles. |

| Multi-Stage Automation | Execute complex sequences automatically without manual intervention. |

| Unmatched Repeatability | Ensure consistent results by eliminating human error in thermal processes. |

| Unattended Operation | Run long cycles automatically, increasing throughput and freeing operator time. |

Ready to elevate your thermal processing with precision and automation? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong deep customization capability, we can precisely meet your unique experimental requirements. Contact us today to discuss how our programmable muffle furnaces can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity