In short, a rotary tube furnace's temperature control system works as a continuous feedback loop. A sensor, typically a thermocouple, measures the internal temperature and converts it into an electrical signal. This signal is sent to a digital controller, which compares the actual temperature to your desired setpoint and precisely adjusts the power sent to the heating elements to eliminate any difference.

The core function of the temperature control system is not just to heat the furnace, but to execute a precise thermal program. It achieves this by constantly measuring the chamber temperature, comparing it to a target, and making real-time power adjustments to ensure the material inside is processed with exceptional stability and accuracy.

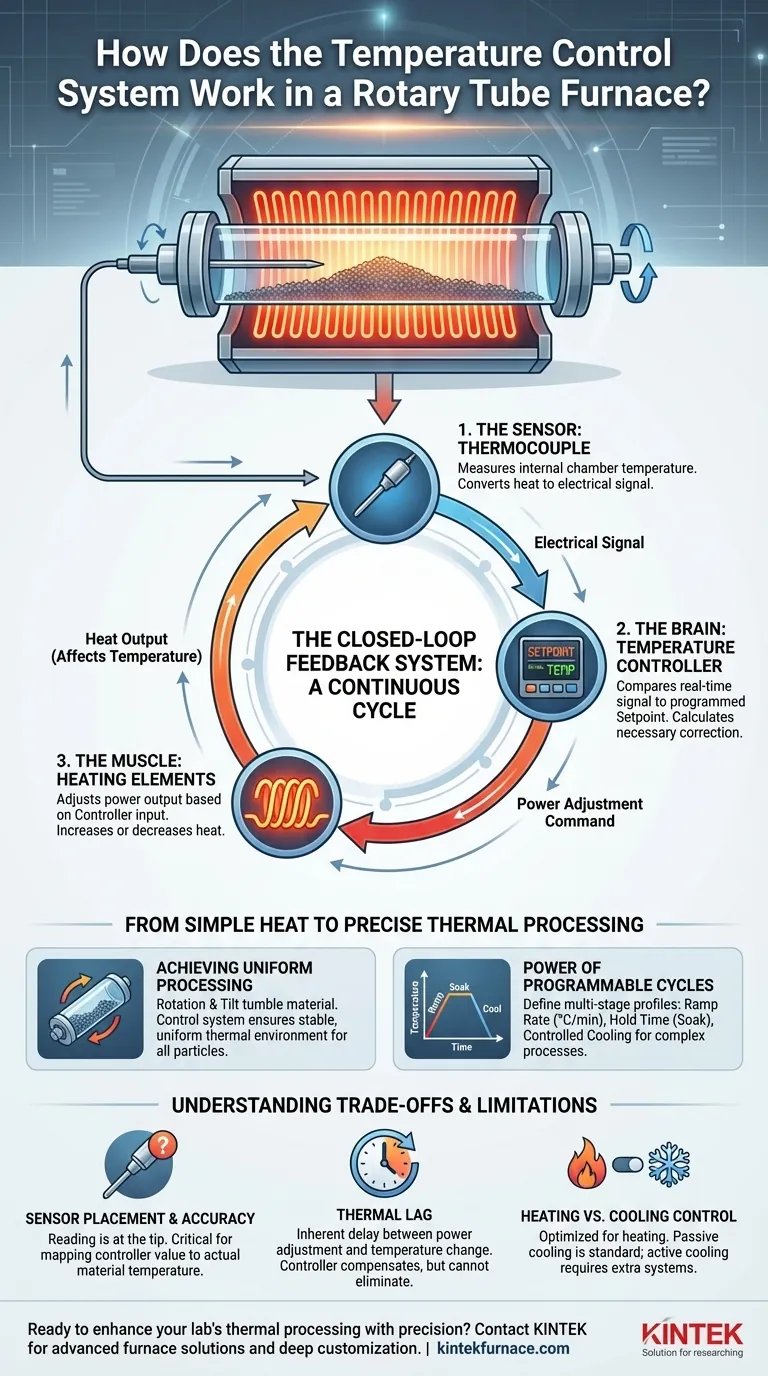

The Anatomy of Temperature Control: A Closed-Loop System

At its heart, the system is a classic example of closed-loop feedback control. It is composed of three primary components working in a continuous, self-correcting cycle to maintain thermal stability.

The Sensor: The Thermocouple's Role

The process begins with the thermocouple. This robust sensor is placed inside the furnace chamber to get an accurate reading of the operational temperature.

It works on a simple principle: when two dissimilar metals joined at one end are heated, they generate a small, measurable voltage. This voltage changes predictably with temperature, allowing it to be converted into a precise temperature reading.

The Brain: The Temperature Controller

The electrical signal from the thermocouple is sent to the temperature controller, which acts as the brain of the operation.

This digital device performs one critical task: it constantly compares the real-time temperature reading from the thermocouple to the setpoint temperature you have programmed into it.

The Muscle: The Heating Elements

Based on the comparison, the controller calculates the necessary correction and adjusts the power output to the electric heating elements lining the furnace.

If the furnace is too cool, the controller increases power. If it is too hot, it decreases or cuts power. This constant modulation is what allows the system to hold a temperature with remarkable precision.

The Feedback Loop in Action

These three components form a loop: the heating elements produce heat, the thermocouple measures the result, and the controller makes adjustments. This measure-compare-correct cycle runs continuously, making dozens or even hundreds of adjustments per minute to keep the temperature locked onto the setpoint.

From Simple Heat to Precise Thermal Processing

Understanding the control loop is only half the story. The true value of a modern system lies in how it enables complex and repeatable thermal processing, which is critical for materials science and manufacturing.

Achieving Uniform Processing

The physical rotation and tilt of the furnace tube ensure your material tumbles and mixes, exposing all particles to the heat source evenly.

The temperature control system complements this mechanical action by providing an incredibly stable and uniform thermal environment. This synergy is what guarantees that every part of your sample receives the exact same thermal treatment.

The Power of Programmable Cycles

Modern controllers are not limited to a single setpoint. They are programmable, allowing you to define a multi-stage thermal profile for your process.

This typically includes:

- Ramp Rate: The speed at which the temperature increases (°C/minute).

- Hold Time (Soak): The duration the furnace stays at a specific temperature.

- Cooling Phase: Controlled or natural cooling periods.

This programmability is essential for processes like annealing, calcination, or complex chemical syntheses that require precise temperature changes over time.

Understanding the Trade-offs and Limitations

While highly effective, this system is governed by physical realities that are important to understand for achieving perfect results.

Sensor Placement and Accuracy

The controller only knows the temperature at the tip of the thermocouple. Its placement is critical. A reading taken near the heating element will differ from one taken in the center of the tube. This is why understanding your furnace's specific thermal profile is key to mapping the controller's reading to the actual temperature of your material.

The Impact of Thermal Lag

There is an inherent delay, or thermal lag, between the controller adjusting power and the material inside the furnace changing temperature. The control algorithm (often a PID controller) is designed to anticipate and compensate for this lag, but it cannot eliminate it entirely. Fast ramp rates can sometimes lead to temperature overshoot for this reason.

Heating vs. Cooling Control

These systems are optimized for heating control. While you can program cooling steps, most standard furnaces cool passively by simply cutting power. Achieving a specific, rapid cooling rate requires a separate, active cooling system (e.g., forced air or water jackets) which adds complexity.

Applying This to Your Process

Your specific goal determines how you should approach using the temperature control system.

- If your primary focus is basic drying or debinding: A simple, single setpoint with a reasonable hold time is typically sufficient.

- If your primary focus is complex material synthesis or crystal growth: You must leverage a programmable controller to define precise ramp rates and multiple soak stages.

- If your primary focus is high-precision annealing or quality control: Pay close attention to thermocouple calibration and placement, and consider performing profile runs to understand the exact relationship between the setpoint and the material temperature.

Ultimately, mastering the temperature control system transforms the furnace from a simple heater into a precision instrument for materials processing.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Thermocouple | Measures temperature inside furnace | Converts heat to electrical signal for accuracy |

| Temperature Controller | Compares actual vs. setpoint temperature | Digital, programmable for multi-stage profiles |

| Heating Elements | Adjusts power based on controller input | Enables precise temperature modulation |

| Feedback Loop | Continuously measures, compares, and corrects | Ensures thermal stability and uniformity |

Ready to enhance your lab's thermal processing with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior results. Contact us today to discuss how we can optimize your processes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing